A different plane welding technology and welding equipment using the same

A plane welding and technology technology, applied in the field of parts processing, can solve the problems of consuming manpower and material resources, increasing processing and manufacturing costs, affecting the focal length of camera lenses, etc., to achieve the effect of saving manpower and material resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

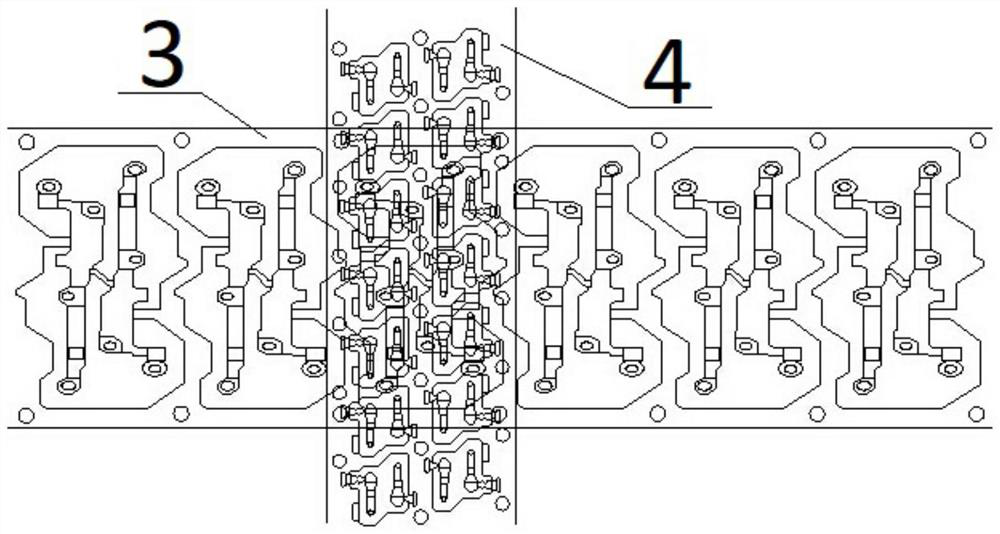

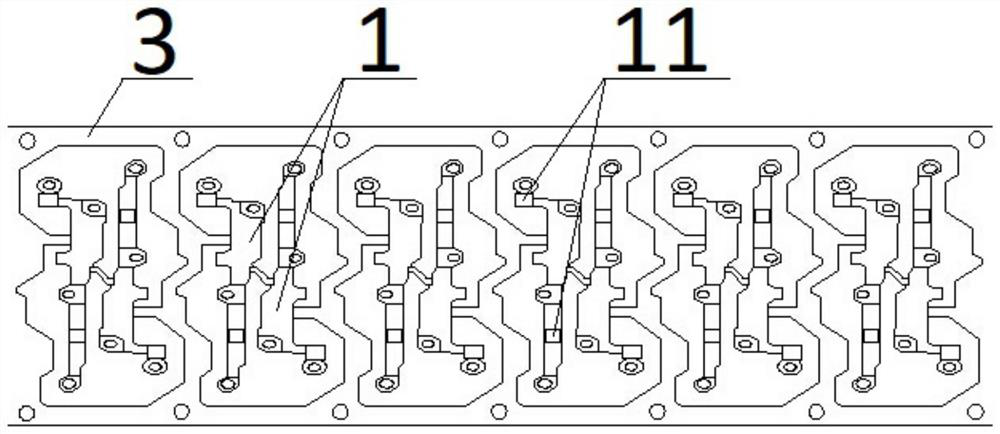

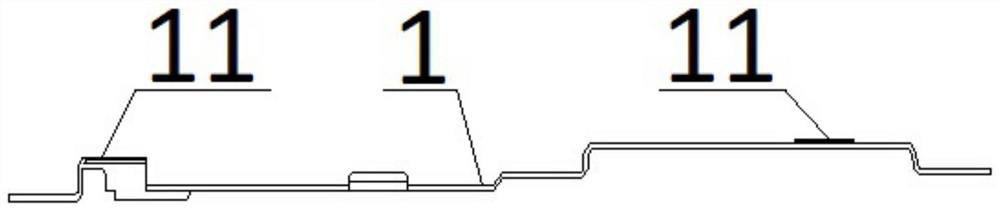

[0029] figure 1 Schematically showing a top perspective view of strips and parts being welded by a different planar welding technique according to an embodiment of the present invention, figure 2 shown figure 1 Top view of large strips and large parts in , image 3 shown figure 2 Side view of the large part in, Figure 4 shown figure 1 Top view of small strips and small parts in . Such as Figure 1-4 As shown, this method is mainly to design the structure of the large part 1 and the small part 2 to be welded to a certain extent, and then feed them on a large material belt 3 and a small material belt 4 respectively, and use the corresponding The equipment simultaneously pulls the large strip 3 and the small strip 4 at different heights, and performs welding work in due course.

[0030] In this embodiment, one large part 1 is welded with two small par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com