Water cutter robot for slotting of construction wall and slotting method for same

A grooving method and robot technology, which are applied to used abrasive processing devices, abrasive jet machine tools, stone processing equipment, etc., can solve the problems of labor-intensive, dusty, and difficult grooving, and reduce dust. The effect of pollution, labor saving, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

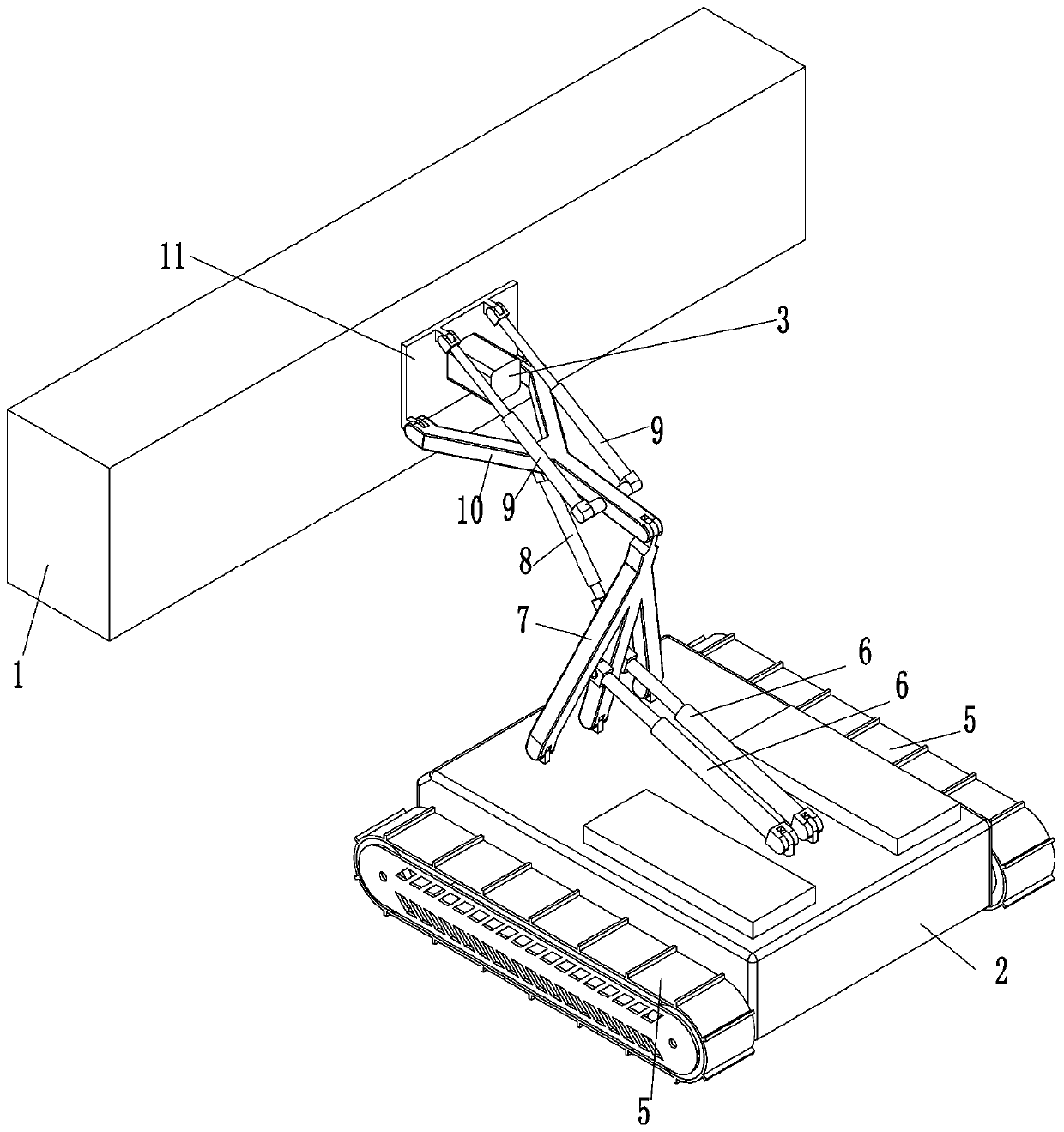

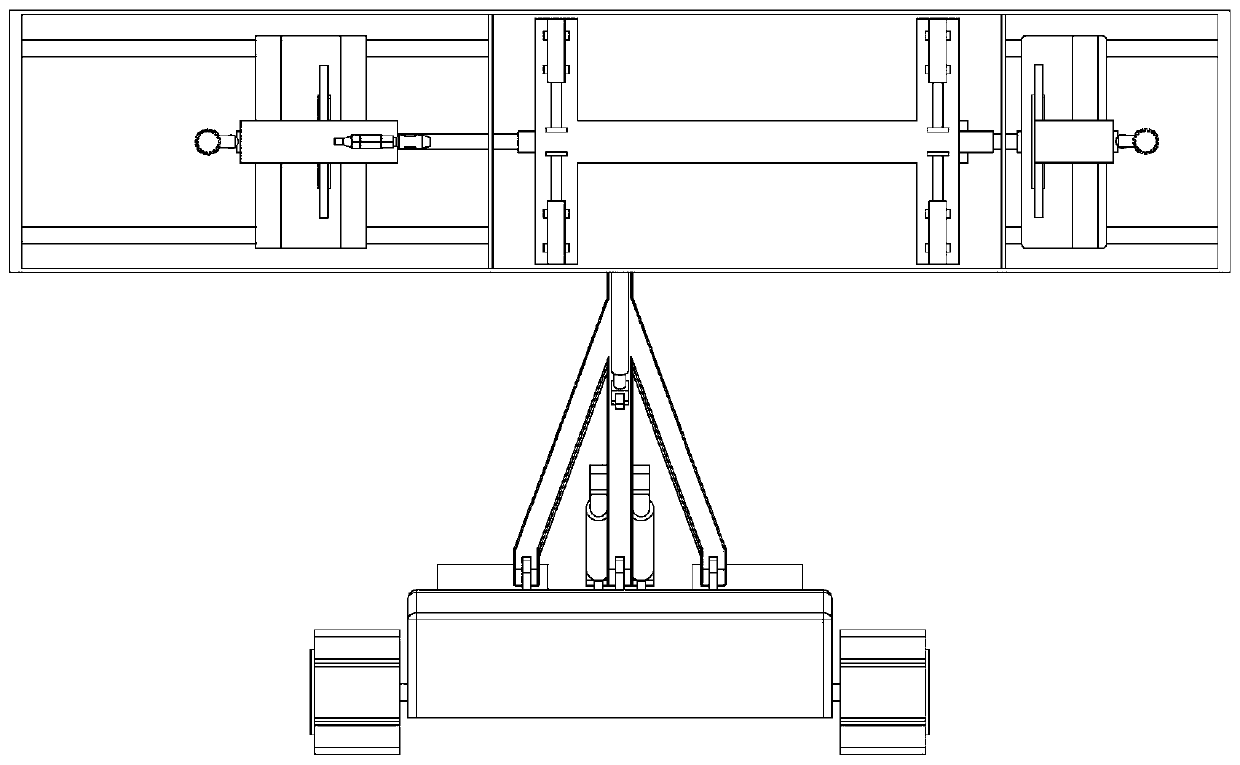

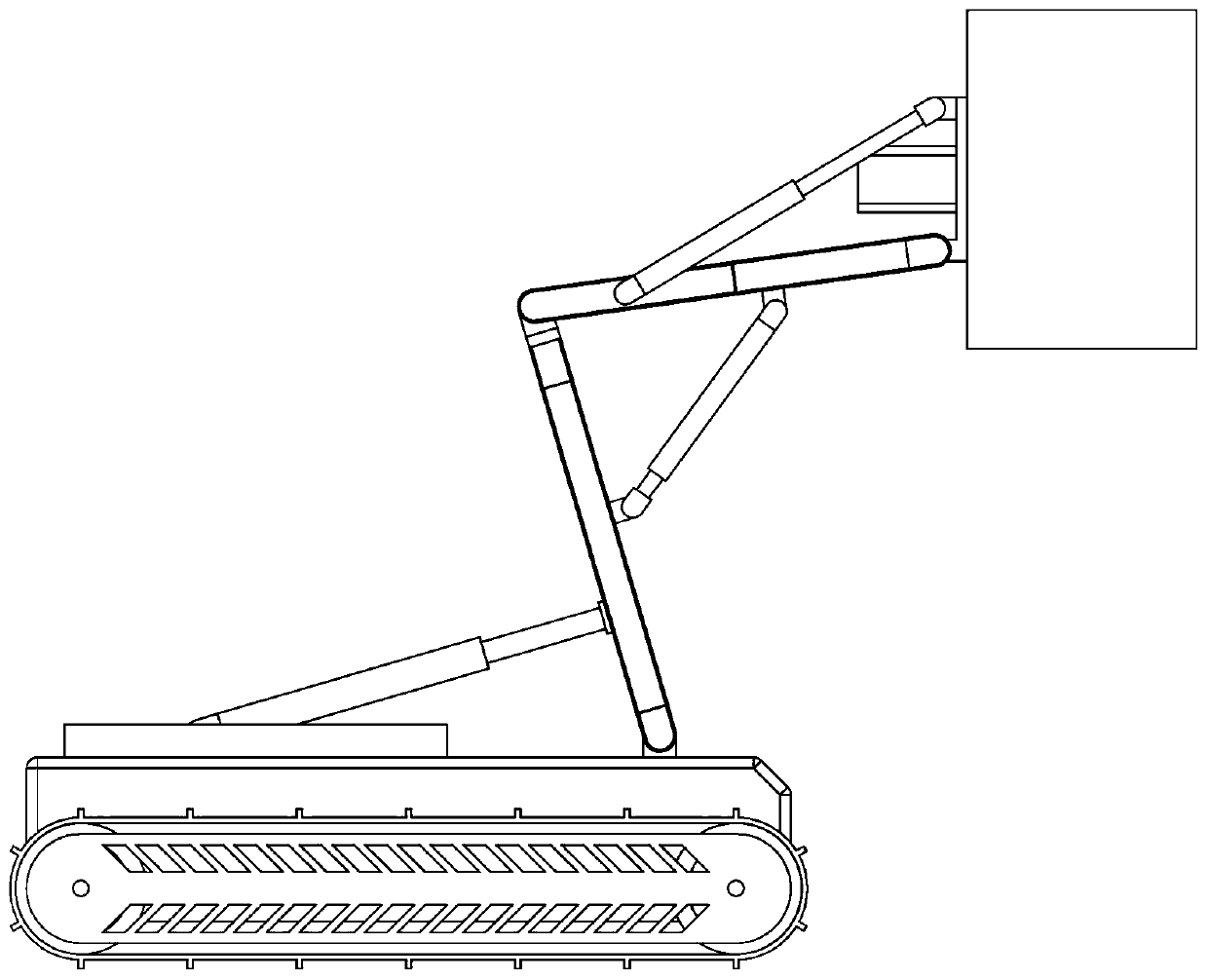

[0035] see Figure 1-15 As shown, a water jet robot for slotting a building wall includes a body 2, and power wheels 5 arranged on both sides of the body 2 for driving the body 2 to move, and the body 2 is hinged with an isosceles triangle The first support frame 7, two first electric push rods 6 for driving the first support frame 7 to rotate around its hinged shaft with the body 2 are arranged side by side on the body 2; A Y-shaped second support frame 10 is hinged at one end away from the body 2, and the first support frame 7 is provided with a first support frame for driving the second support frame 10 to rotate around its hinged axis with the first support frame 7. Two electric push rods 8; the first mounting plate 11 is hinged on the end away from the first support frame 7 on the second support frame 10, and two are arranged side by side for driving the first installation plate 11 on the second support frame 10. The third electric push rod 9 that the plate 11 rotates ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com