Flexible clutch-braking method of press clutch brake

A technology of clutches and brakes, which is applied in the field of presses, can solve problems such as clutches and brakes being unclear, unclear, and interference, and achieve the effects of reducing friction damage and mechanism impact, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

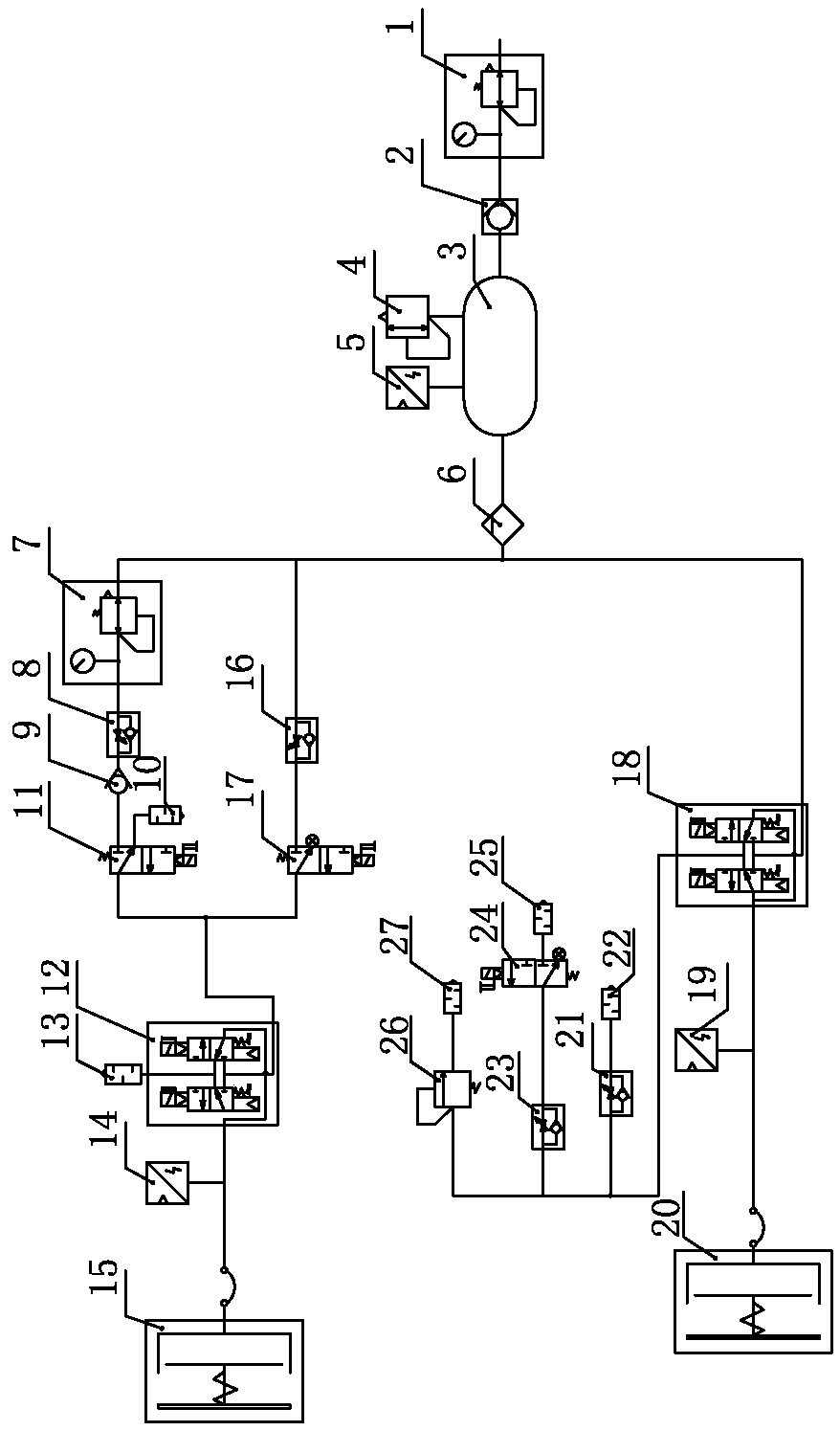

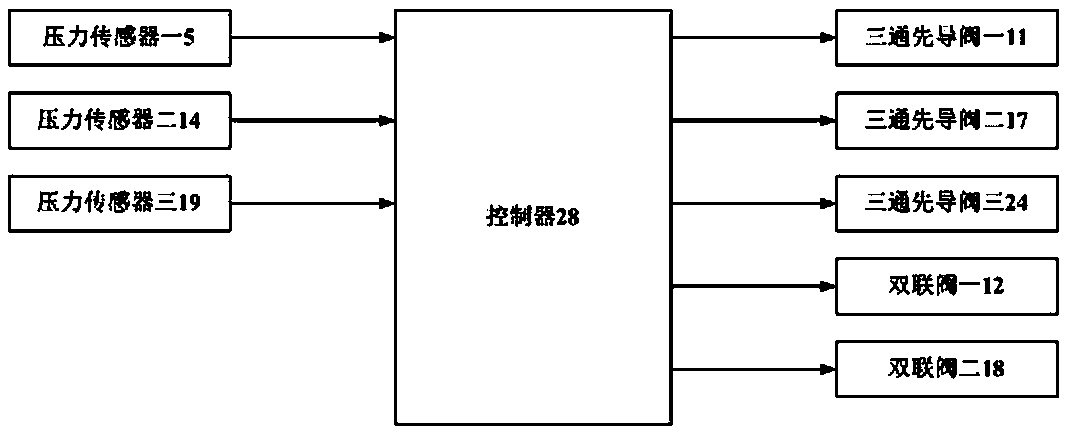

[0015] like figure 1 and figure 2 Shown is the flexible clutch-brake system based on the flexible clutch-brake method of the press clutch brake of the present invention, including the gas storage tank 3, and the branch of the air outlet pipeline of the gas storage tank 3 is connected with the clutch gas supply air circuit and the brake Air supply air circuit, the front branch of the clutch air supply air circuit is provided with a soft clutch branch and a fast clutch branch, and the rear section of the clutch air supply circuit combined at the outlet of the soft clutch branch and the fast clutch branch passes through the first double The valve 12 is connected to the clutch cylinder 15, and the first pressure sensor 14 is also connected to the air supply path between the clutch cylinder 15 and the first double valve 12; Two pressure sensors 19 and a brake cylinder 20.

[0016] In order to ensure the stability of the air pressure in the gas storage tank 3, the air intake pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com