Tyre anti-skid device

An anti-skid device and tire technology, applied in the directions of wheels, wheel accessories, transportation and packaging, etc., to achieve good application prospects, improve safe driving, and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

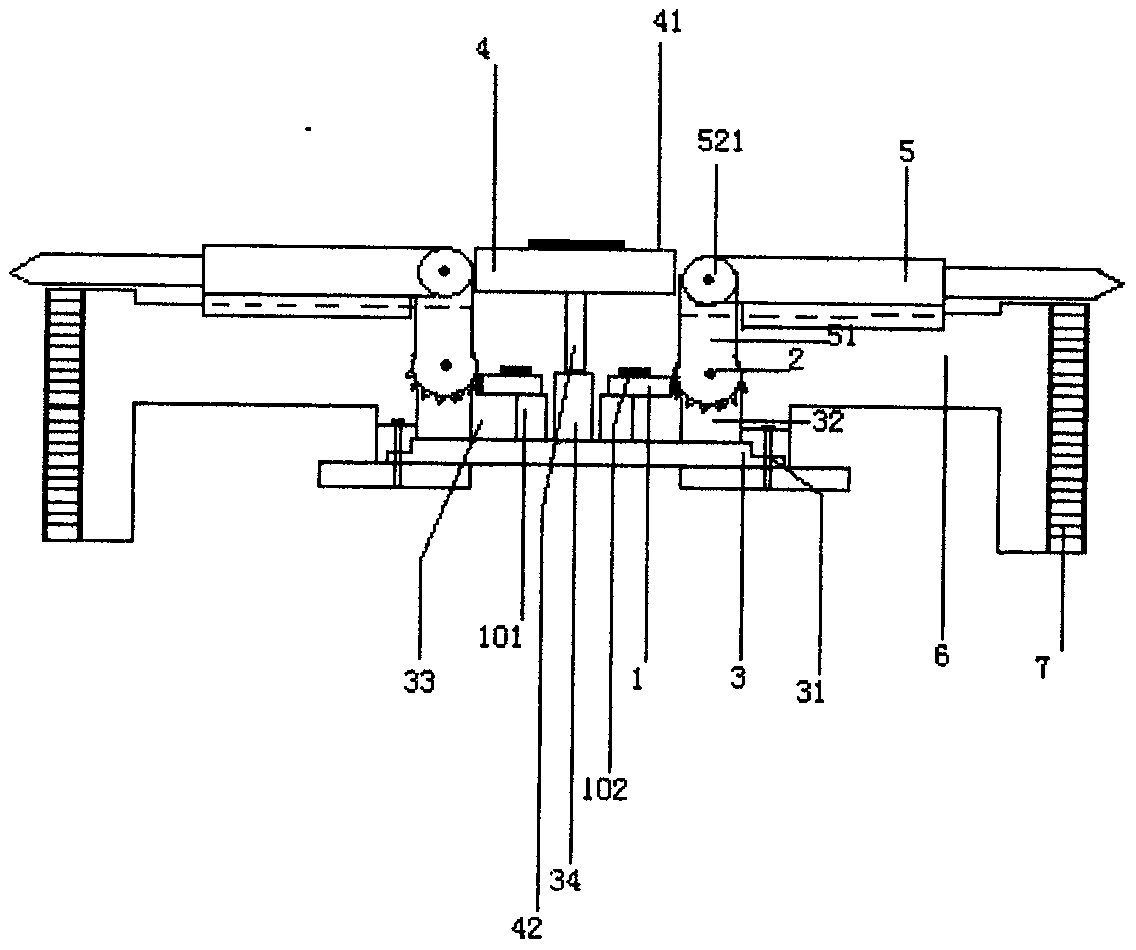

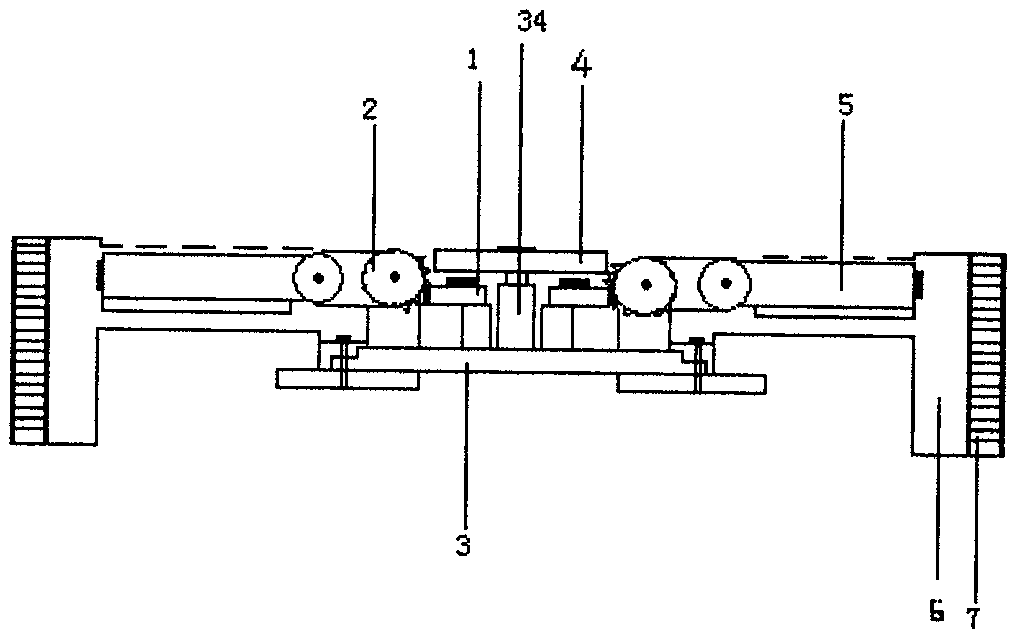

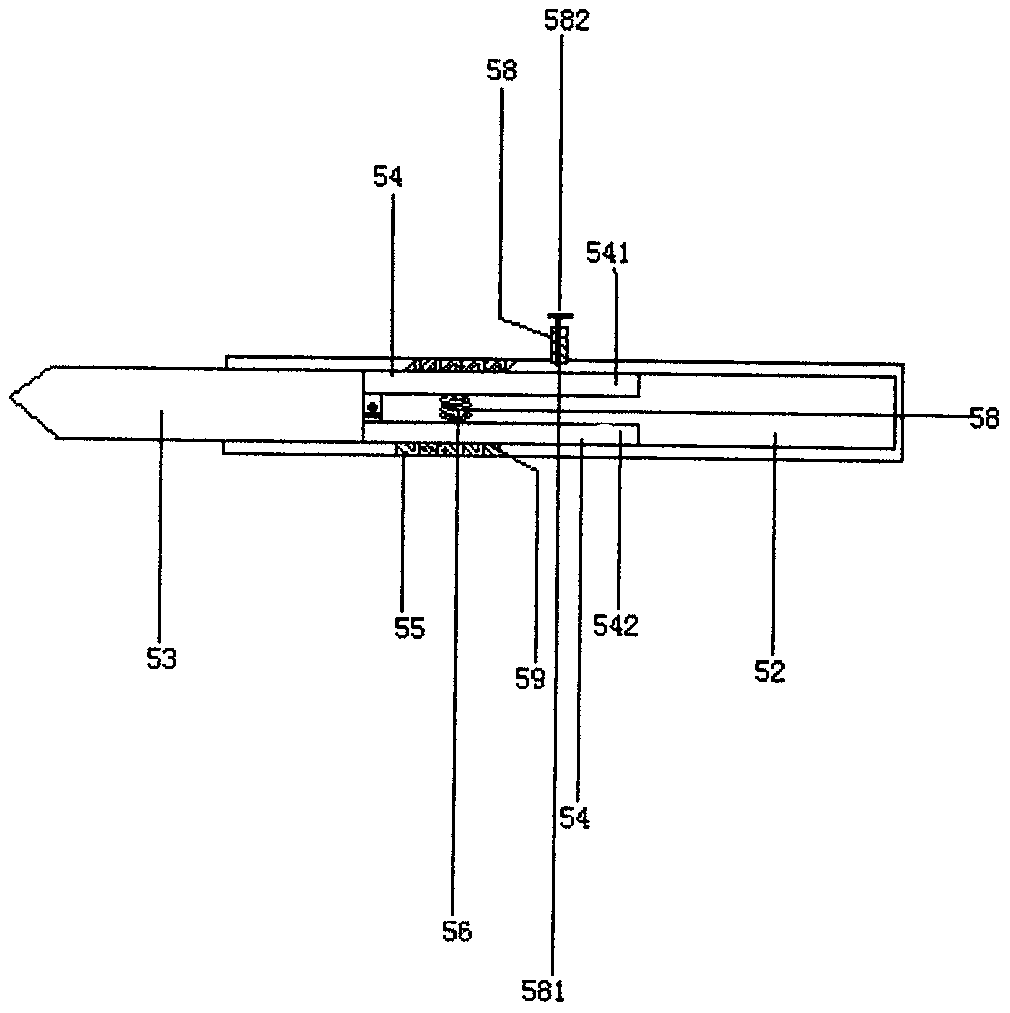

[0015] figure 1 , 2 , Shown in 3, 4, a kind of tire anti-skid device, comprises the conical large gear 1 that has opening in the middle, helical gear 2, also has fixed disk 3, positioning disk 4, telescopic arm equipment 5, ring fixed disk 3 The outer side has a plurality of fixing holes 31 at certain equidistant intervals, and five supporting plates 32 are welded at certain equidistant intervals at the front end of the ring fixed disk 3, and a bearing seat is welded on the front upper side end of each supporting plate 32, and the bearing A shaft is installed in the bearing inner ring of the seat, and the helical gear 2 has the same five, and the shaft hole in the middle of each helical gear 2 is installed horizontally on the upper end of the shaft of each support plate bearing seat, and screwed into the screw through a nut The upper external thread is fixed, and the rear end of each helical gear 2 is a semicircular helical tooth structure. A bearing seat 33 is welded in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com