PTFE (polytetrafluoroethylene) sewing thread and preparation technique thereof

A technology of PTFE and sewing thread, applied in the field of sewing thread structure, can solve the problem of scattered thread ends and difficult to find, and achieve the effects of eliminating the need to search for thread ends, high installation and fixing strength, and reasonable and effective preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

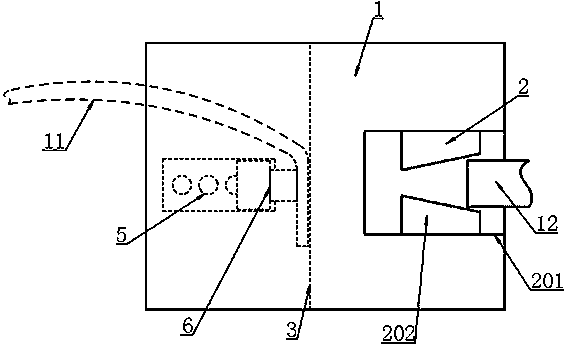

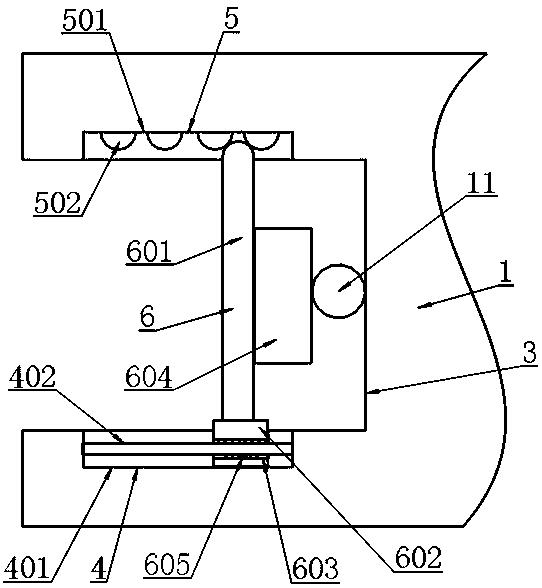

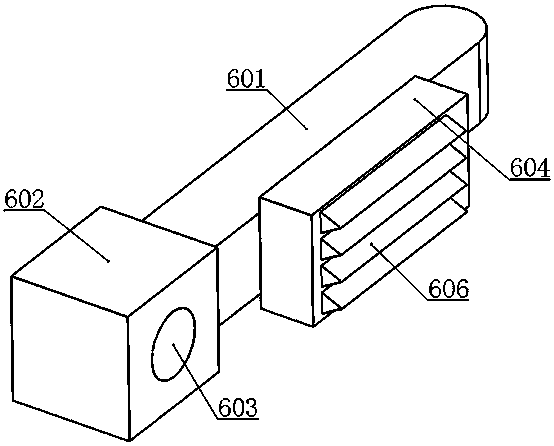

[0026] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, a PTFE sewing thread includes a PTFE thread body 11, and also includes a thread end marking block 1, which is arranged on the side of the thread end marking block 1 and is used for clamping and fixing the board body clamping unit 2 on the desktop board 12 , the thread body fixing groove 3 arranged on the side of the thread head marking block 1, the in-slot inserting unit 4 and the in-slot engaging unit 5 respectively arranged on two opposite inner sides of the thread body fixing groove 3, and The two ends are respectively arranged on the plug-in unit 4 in the groove and the engaging unit 5 in the groove, and are used to press and fix the PTFE wire on the inner side of the wire body fixing groove 3 by sliding and pressing. The slide plate unit 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com