Laser cutting fed material and baiting conveyor

A laser cutting and conveyor technology, used in glass cutting devices, glass manufacturing equipment, electrical components, etc., can solve problems such as the inability of the scribing effect to meet the requirements for use, the wrong alignment of the battery plate, and the flawed scribing. To achieve the effect of shortening process production time, improving productivity and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

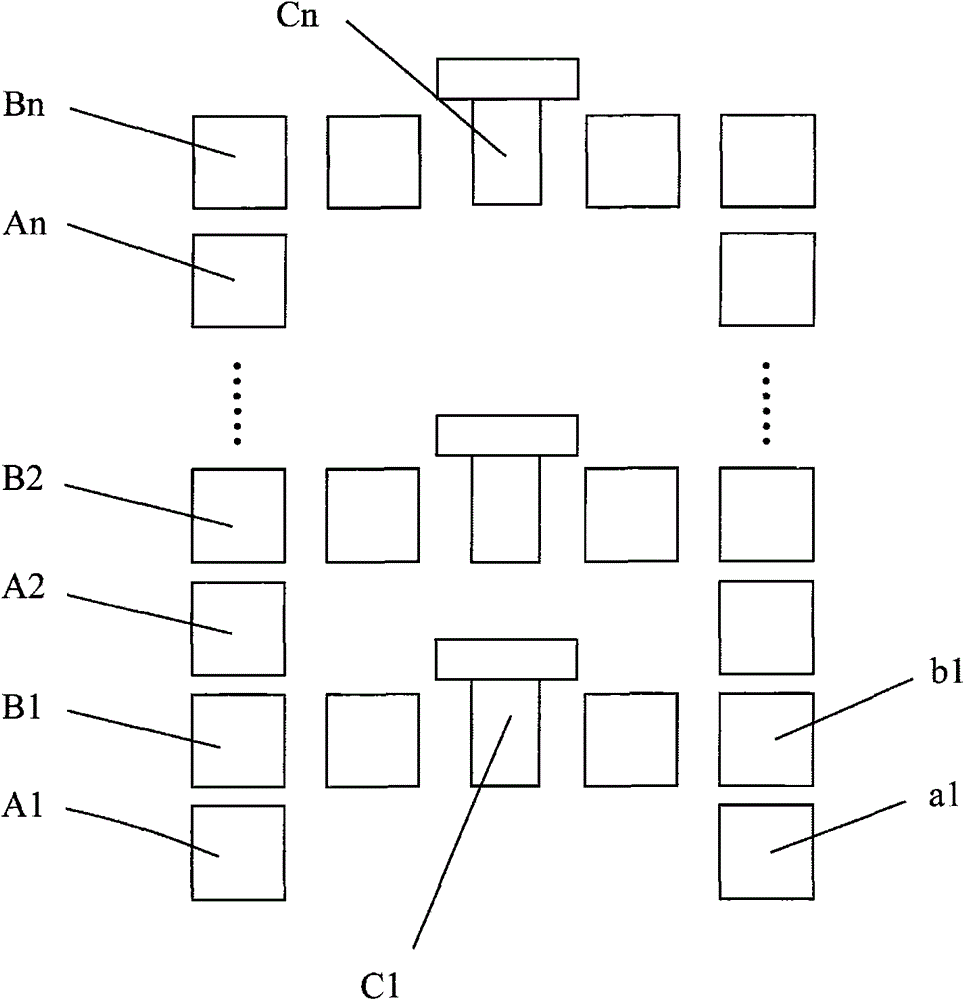

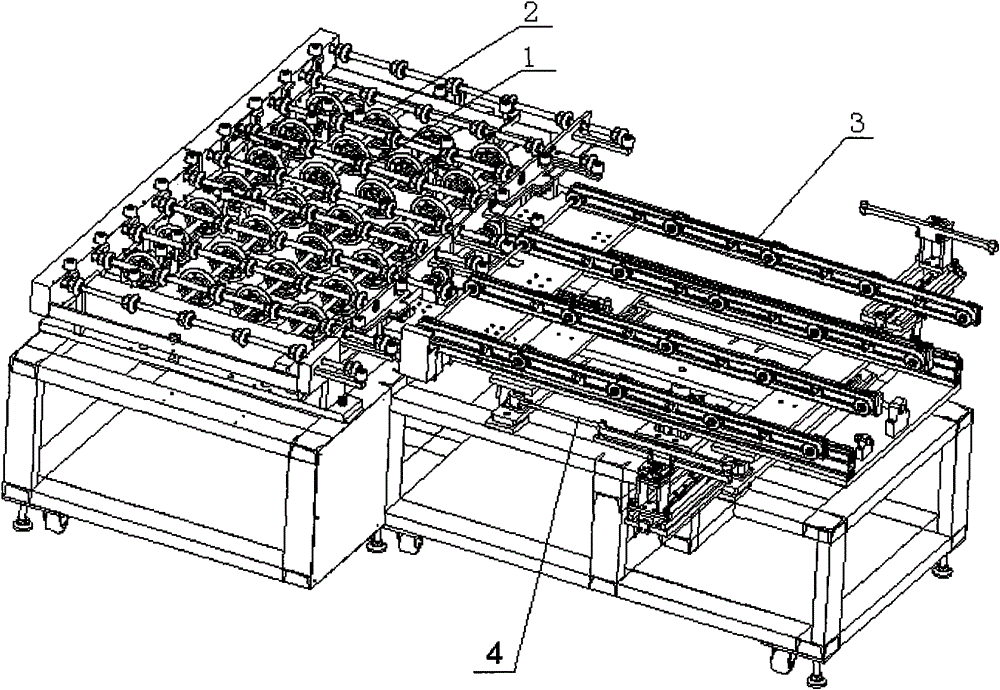

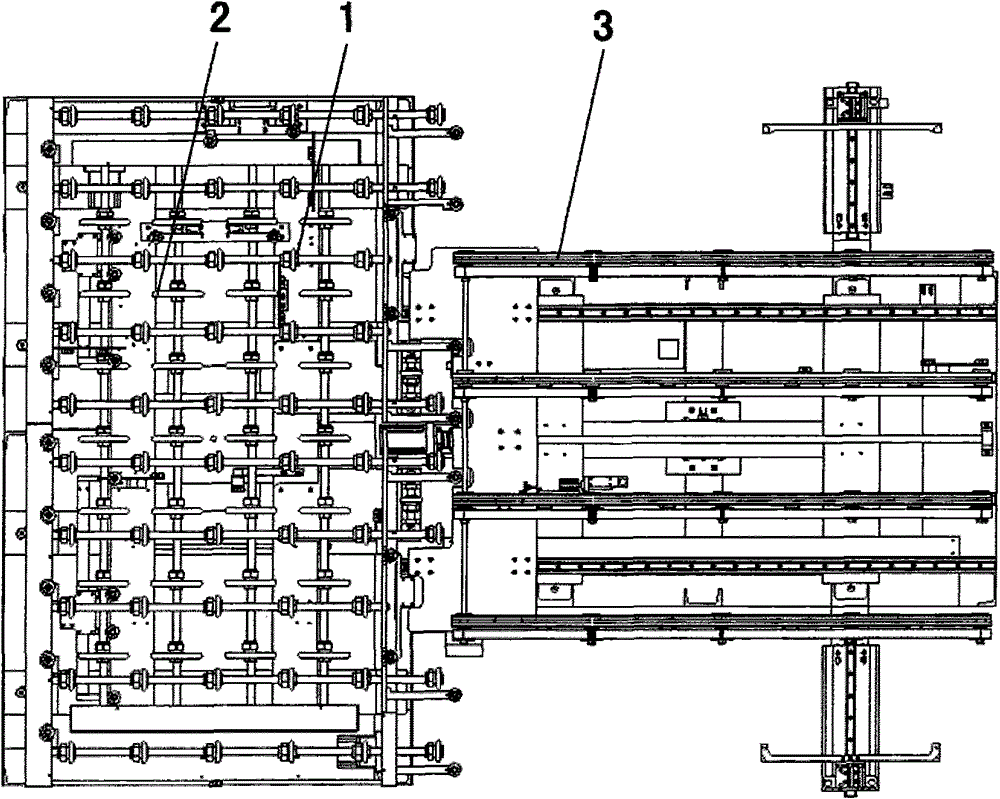

[0028] Such as figure 1 As shown, the laser cutting loading and unloading machine involved in the present invention includes n feeding machine transmission mechanisms, loading cross guide rollers, unloading machine transmission mechanisms, and unloading cross guide rollers. The conveying mechanism of the feeding machine is arranged on one side of the laser marking machine (C1~Cn in sequence), arranged in a straight line, A1~An in sequence. The feeding cross guide rollers and the feeding machine conveying mechanism are arranged alternately, B1~Bn in sequence. The conveying mechanism of the unloading machine (b1~bn in sequence) and the unloading cross guide roller are set on the other side of the laser marking machine, and the arrangement between the two is the same as the arrangement of the feeding conveying mechanism and the feeding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com