Thermal power generating unit heater terminal difference self-adaptive adjusting method and device

A technology of self-adaptive adjustment and thermal power unit, which is applied to feed water heaters, lighting and heating equipment, preheating, etc., can solve the problems of high labor intensity, inconvenient calculation of heaters, and failure of heaters to operate, etc., to achieve non-disturbance switching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

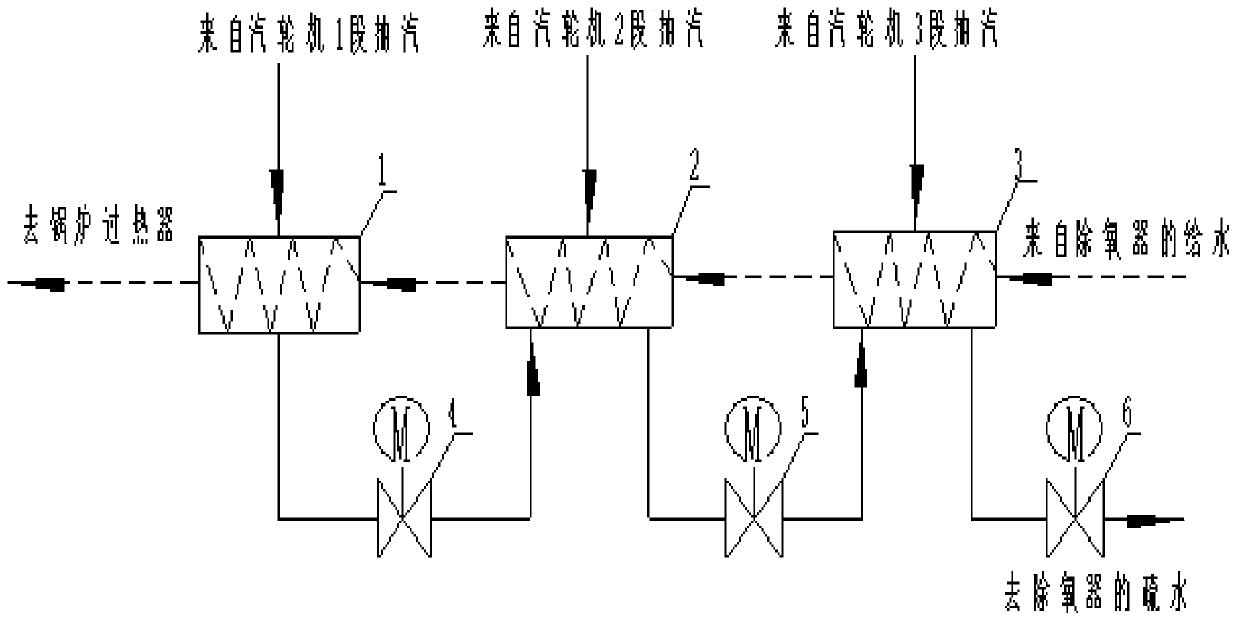

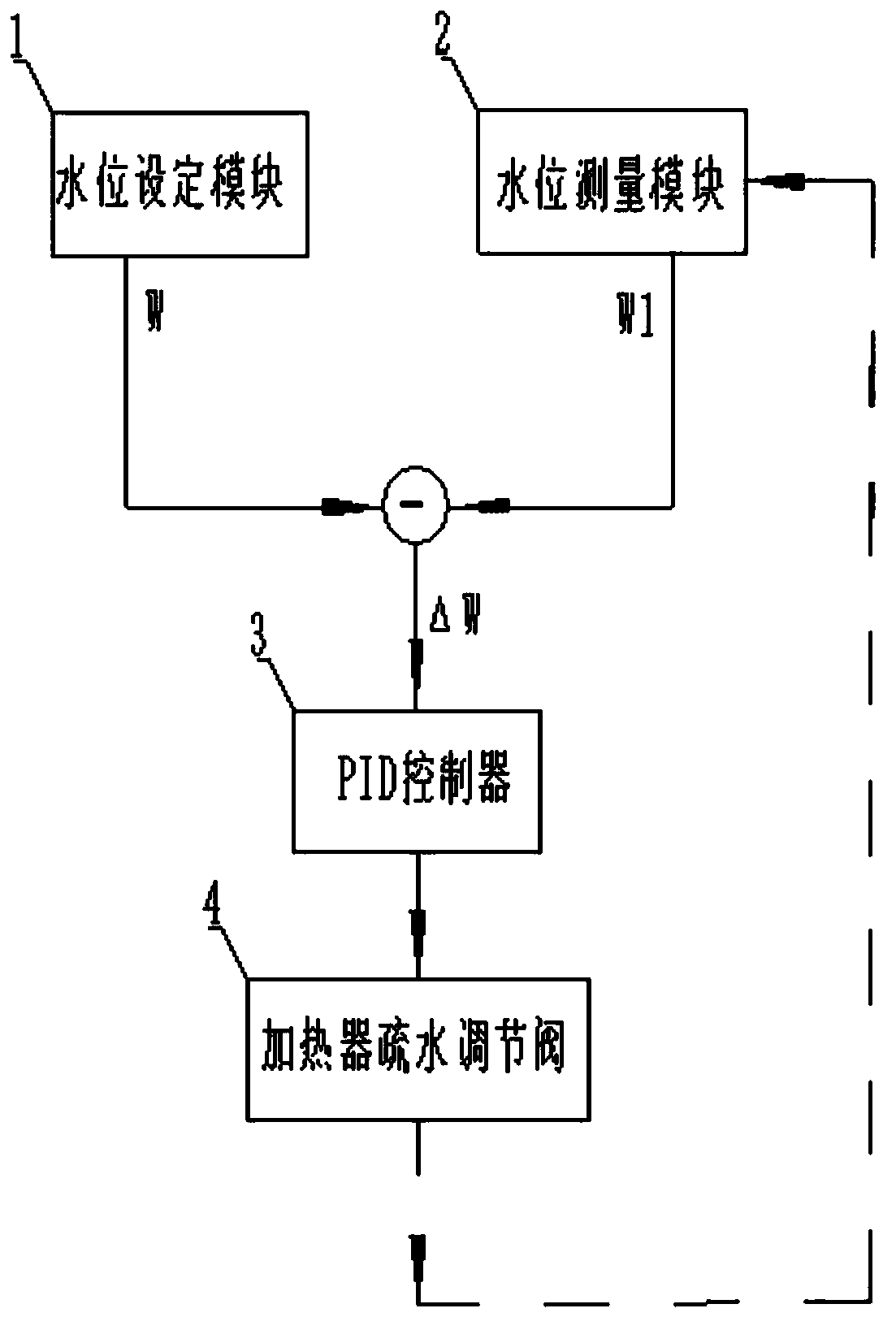

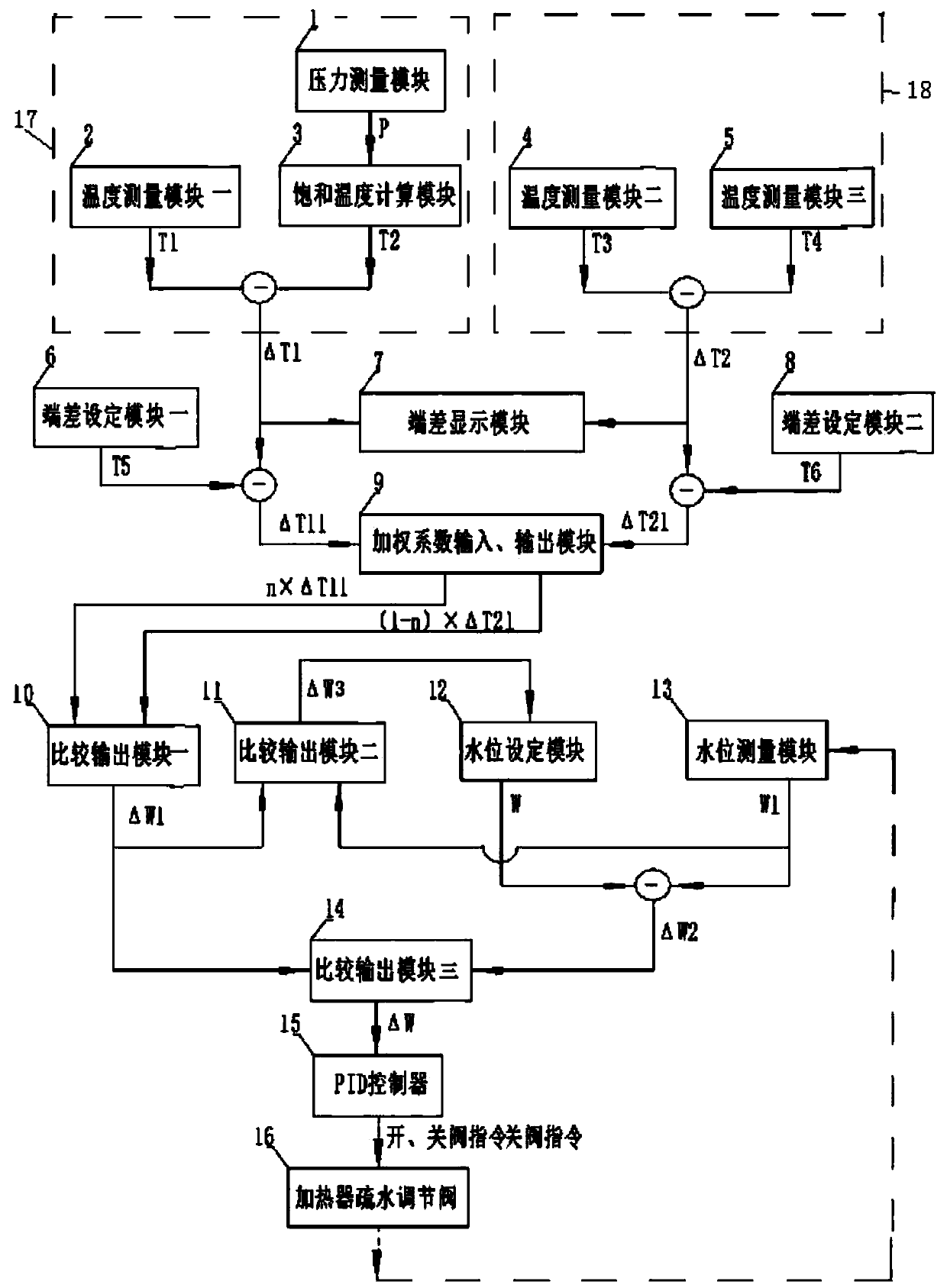

[0036] Embodiment 1: as image 3 As shown, a thermal power unit heater terminal difference adaptive adjustment method, the method includes the following steps:

[0037] (1) After the high-pressure heater end difference automatic control system is put into use, the pressure measurement module 1 measures the extraction steam pressure P of the heater in real time and sends it to the saturation temperature calculation module 3, and the saturation temperature calculation module 3 calculates the corresponding pressure P according to the pressure P value. Saturation temperature value T2;

[0038] (2) The difference ΔT1 between the calculated saturation temperature T2 and the measured temperature T1 measured by the temperature measurement module 1 2 is the upper end difference of the heater; at the same time, the temperature measurement module 2 4 and the temperature measurement module 3 5 respectively measure the inlet water of the heater The temperature T3 and the hydrophobic tempe...

Embodiment 2

[0046] Embodiment 2: as image 3 As shown, a thermal power unit heater end difference adaptive adjustment device, including a temperature measurement module 2, a pressure measurement module 1, a temperature measurement module 2 4, a temperature measurement module 3 5, a water level measurement module 13, a controller and a heater Drain regulating valve 16, temperature measurement module 1 2, pressure measurement module 1, temperature measurement module 2 4, temperature measurement module 3 5 and water level measurement module 13 are all electrically connected to the signal receiving end of the controller, and the control end of the controller is connected to the heating The controller is electrically connected to the drain regulating valve 16, the human-computer interaction terminal of the controller is electrically connected to the touch screen (or DCS system), the temperature measurement module 1 is used to measure the outlet water temperature of the high pressure heater, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com