Part molded surface contour detection method

A detection method and surface profile technology, applied in the direction of measuring devices, mechanical counters/curvature measurement, instruments, etc., can solve the problems of deviation of detection results, inaccurate positioning of reference points, high equipment costs, etc., to reduce detection errors and improve Convenience, weight reduction effect

Inactive Publication Date: 2019-07-26

陈剑

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this detection process, the positioning of the reference point is very important. Inaccurate positioning of the reference point will lead to deviations in the detection results.

However, each time the operator is different, the operating habits are different, the environment changes, the reference point is different, the repeatability of the operation is very low, and the reliability and stability of the detection are low.

In addition, the cost of equipment is high, the operation is complicated, and the process needs to be combined with the program or the extraction of the surface and the selected reference point to complete the detection, and the process is complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

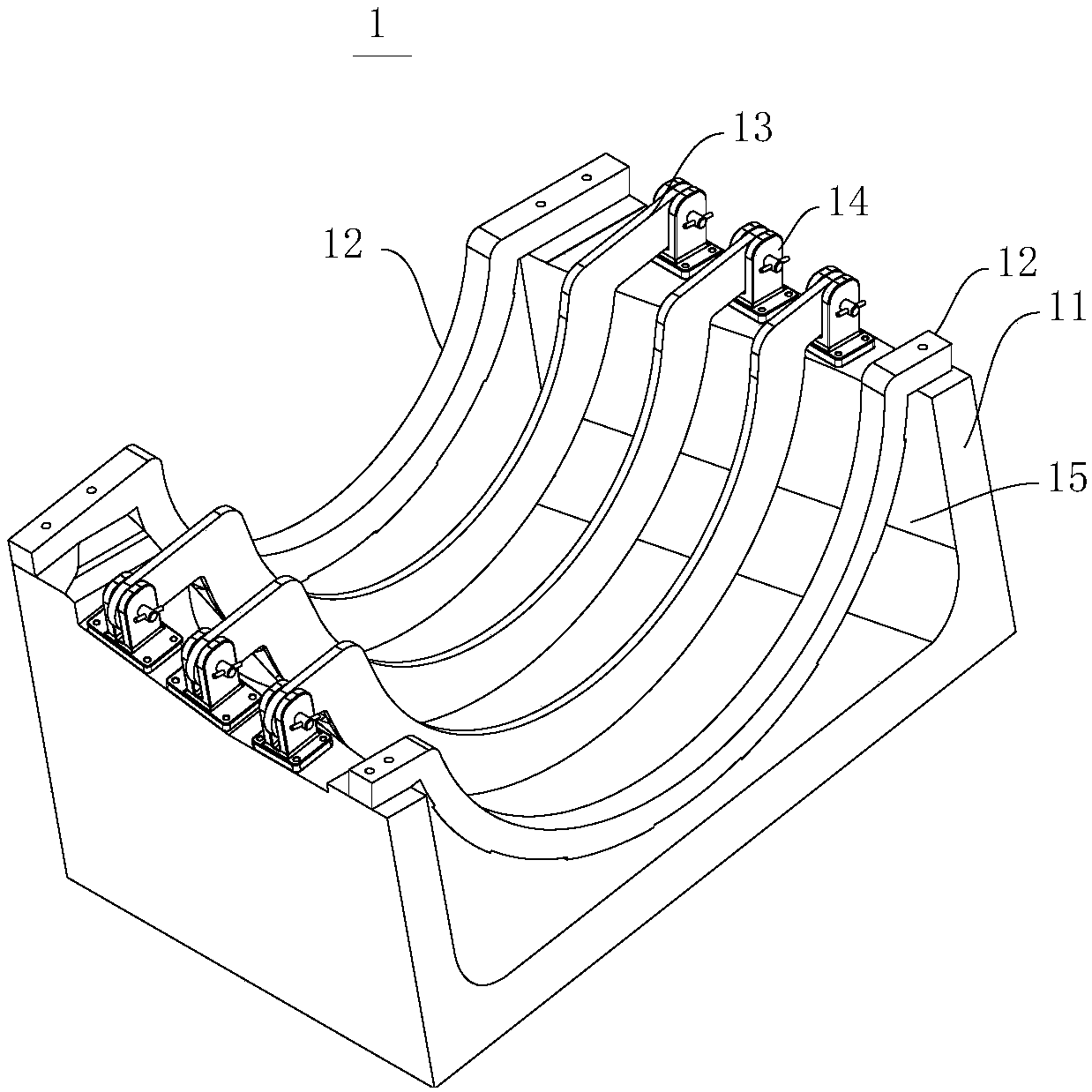

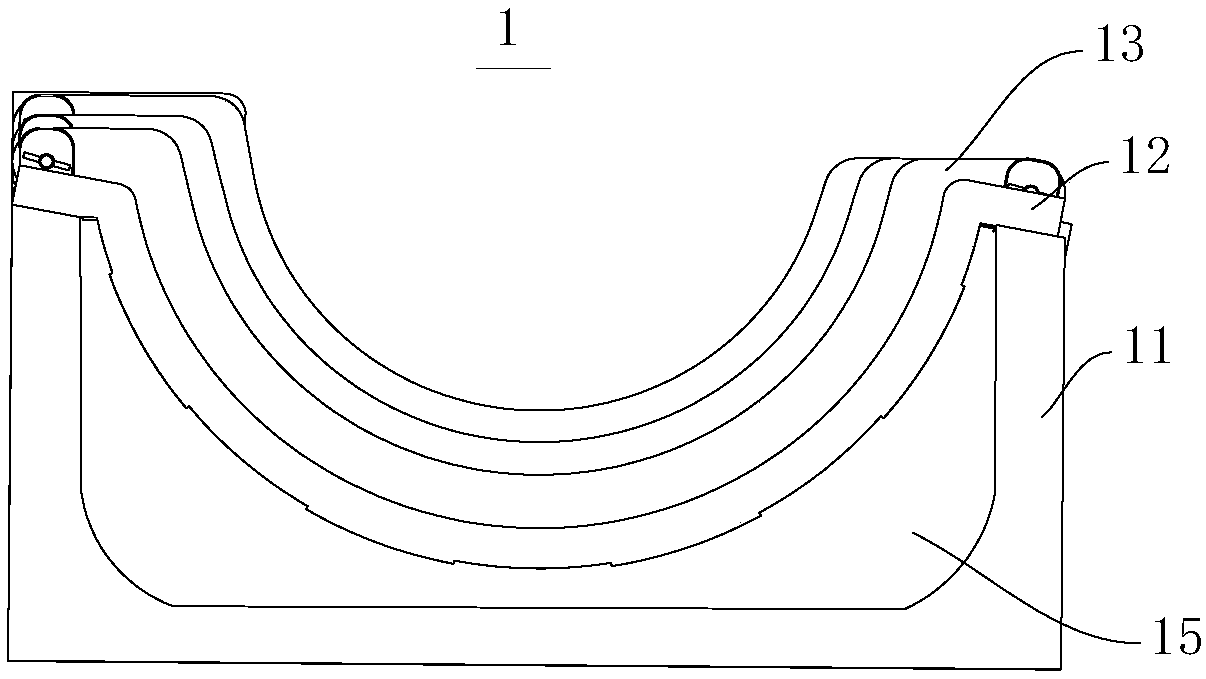

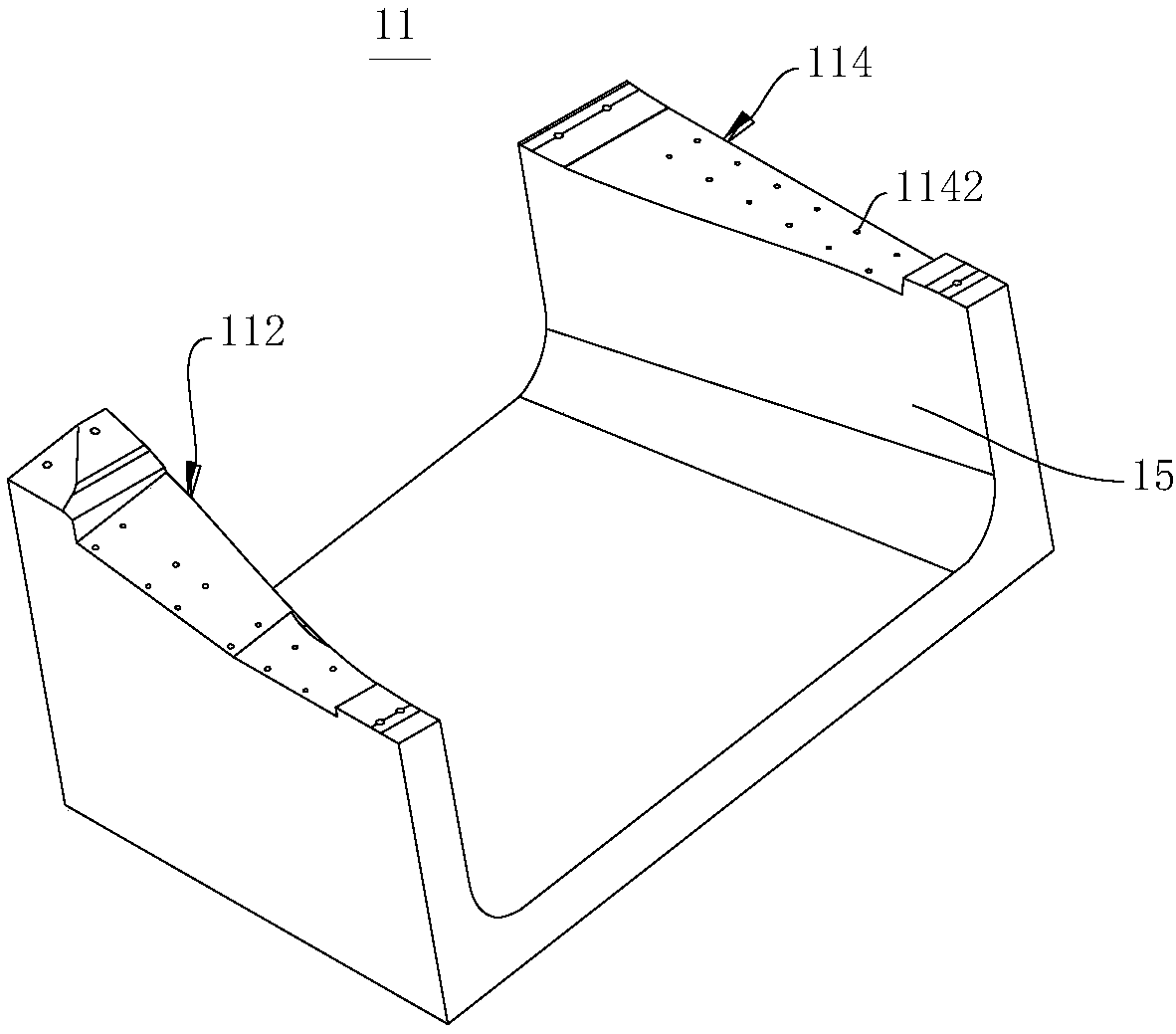

[0051] see Figure 1 to Figure 7 . The embodiment of the present invention provides a method for detecting the surface profile of a part, which is carried out by using a detection fixture 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of quality detection, in particular to a part molded surface contour detection method. A detection fixture is used in the detection method. The detection fixture comprises a base and clamping blocks, wherein the base and the clamping blocks are connected and form a clamping cavity; a first fitting surface is arranged on the base, and the first fitting surface adapts to one molded surface of a part in a design standard; and the clamping cavity is used for containing the to-be-detected part. The detection method comprises the steps that S1, the to-be-detected part is placed in the clamping cavity, and the molded surface of the to-be-detected part is fit with the first fitting surface on the base; and S2, a feeler gauge is placed between the molded surface of the to-be-detected part and the first fitting surface. Through the detection method, it is not needed to find a datum point on the part, and therefore the adverse influence of human factors on a detection result can be avoided; and besides, the detection method is simple in operation process and beneficial to rapid detection on molded surfaces of batch parts.

Description

technical field [0001] The invention relates to the field of quality inspection, in particular to a method for inspecting part profiles. Background technique [0002] The profile of the part refers to the surface on the part that requires high molding quality. Whether the profile of the profile meets the requirements is related to whether the processing quality of the part reaches the standard. After the machining of the part is completed, the profile of the part needs to be inspected to verify whether the profile of the part meets the design standard. Especially for parts with aerodynamic shape, most of these parts have a lot of curvature changes and uneven thickness. Due to the aerodynamic shape, the requirements for the shape are very high. In the existing technology, most of the detection methods for the profile of parts are by means of external equipment, such as measuring arms. The detection of these equipment needs to locate the reference point on the part, and fit t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B5/20G01B21/20

CPCG01B5/20G01B21/20

Inventor 贾娜陈剑漆松林李璐璐吴鸿瑞钟红莲石小平高超

Owner 陈剑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com