Disinfection cabinet control method

A control method and disinfection cabinet technology, applied in the direction of disinfection, program control, computer control, etc., can solve the problems of waste of resources, long time, incomplete sterilization, etc., to prevent omissions and dead ends, improve detection accuracy, and realize disinfection Intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

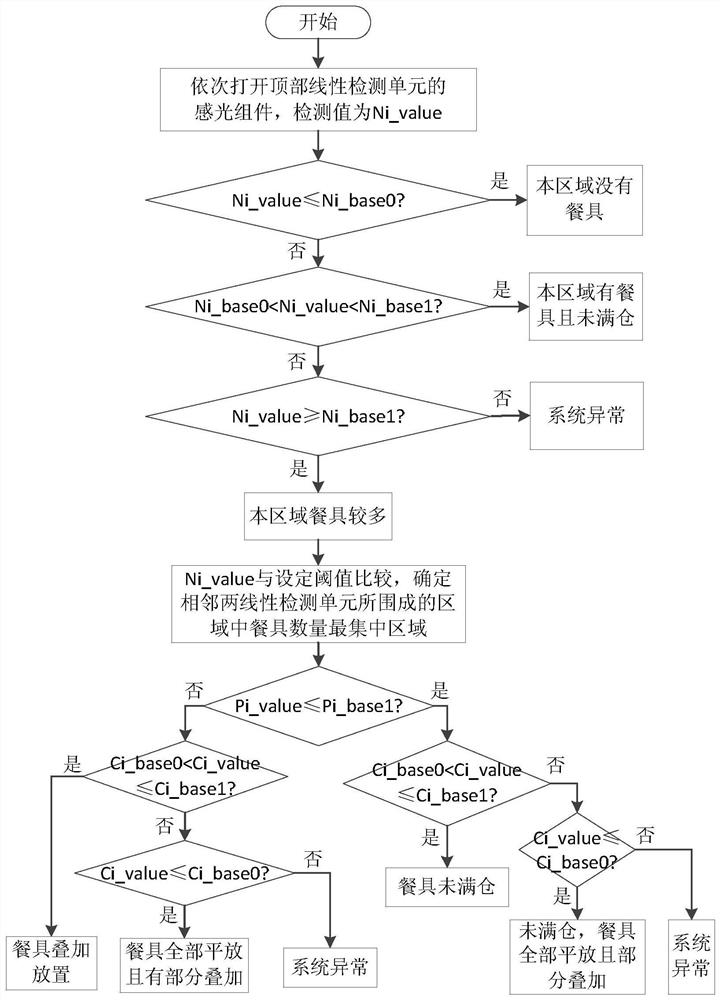

[0029]The present invention will be further described in detail below with reference to the accompanying drawings embodiments.

[0030]Disinfection of the present embodiment has a tableware cabinet detecting means, temperature detecting means, ultraviolet ray intensity detecting means, humidity detecting means, UV lamps, heating means, and the exhaust system ozone sensor. Wherein the temperature detecting means, ultraviolet ray intensity detecting means, humidity detecting means, UV lamps, heating means, and exhaust system are conventional ozone sensor structure, detecting by detection means dishware means multiple pieces of the photosensitive components.

[0031]Roof lumen center point sterilizer embodiment of the present embodiment are respectively formed with four vertices four linear connection detecting unit, the detecting unit four linear lumen roof plane into four triangular shape detecting units, each detecting unit linear and each detection unit is provided with a flat top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com