Conveying belt

A conveyor belt and core technology, which is applied in the field of conveyor belts, can solve problems such as accelerating the replacement process of conveyor belts and breaking the antistatic layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

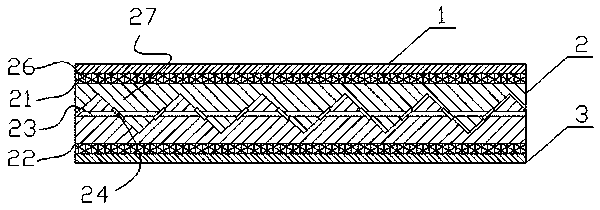

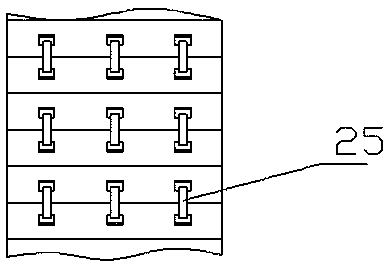

[0015] A kind of conveyer belt as shown in the figure, comprises: glue layer 1, core body layer 2 and primer layer 3 connected successively, and described core body layer comprises upper core body layer 21, lower core body layer 22 and several steel Cord 23, the lower side of the upper core layer and the upper side of the lower core layer are in a wavy shape interlocking; the peaks of the lower side of the upper core layer and the peaks of the upper side of the lower core layer are respectively Correspondingly, several steel cord grooves 25 are provided, so that steel cord tunnels are formed inside the core layer, and the steel cords are located in the steel cord tunnels; sheet 24, and the limiting sheets are located at the connection seam between the upper core layer and the lower core layer.

[0016] By setting the core layer as an upper cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com