Triangle adjustment tooling and adjustment method for sinker of circular knitting machine

A technology for circular knitting machines and adjustment methods, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of affecting the uniform distribution of sinker triangles, time-consuming and labor-intensive adjustment of the machine, and difficult to find high points. Achieve the effect of improving adjustment efficiency and time, improving accuracy, and reasonable triangular distribution of sinkers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

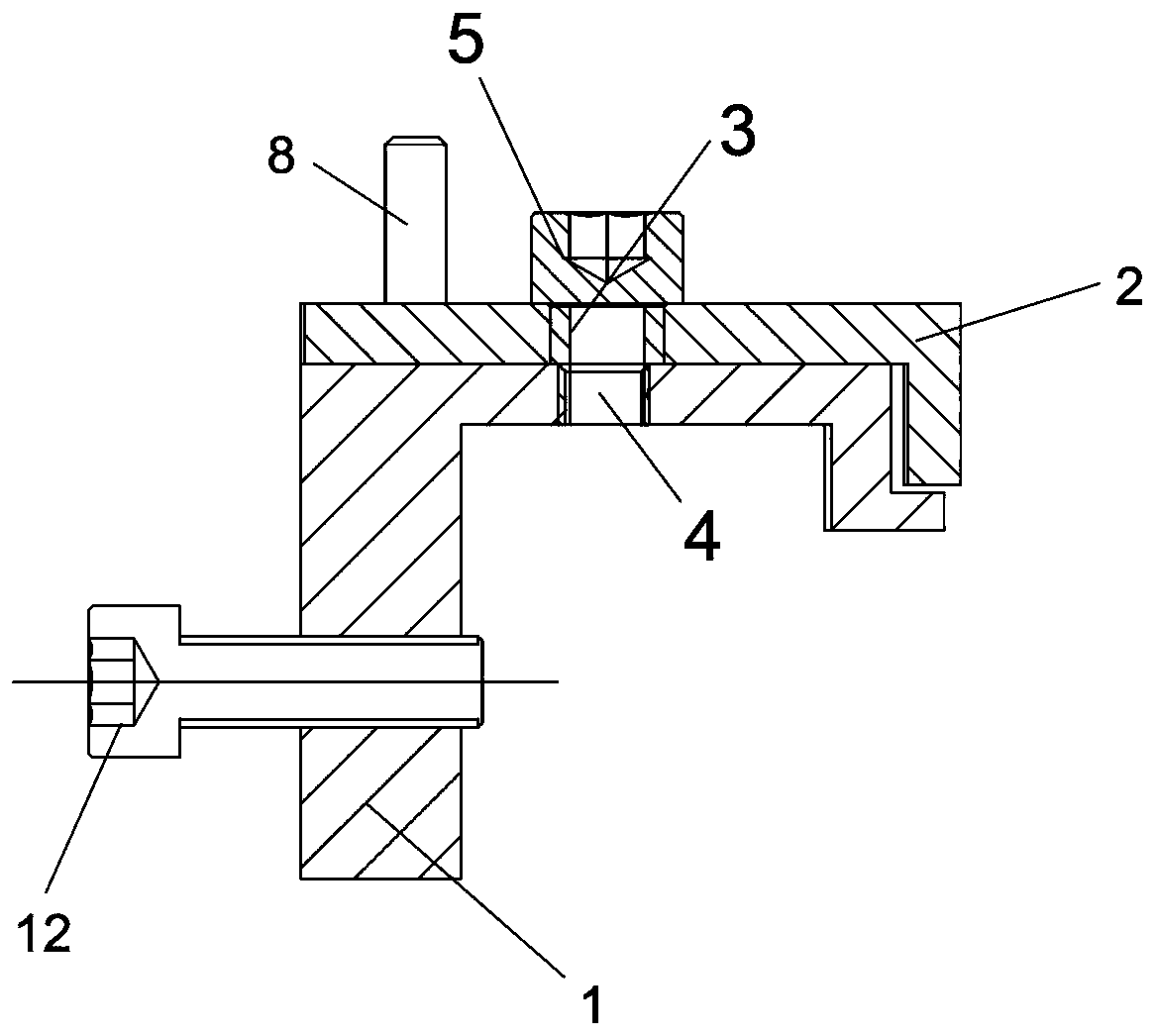

[0036] see Figure 1-3 , the present invention provides a sinker triangle adjustment tool for a circular knitting machine, comprising a fixed seat 1 and a movable seat 2, the movable seat 2 is movably arranged on the fixed seat 1, and the fixed seat 1 is provided with a second A through hole 3, correspondingly, a second through hole 4 is provided on the movable seat 2, when the movable seat 2 is fitted on the fixed seat 1, the first through hole 3 is aligned with the second through hole 4, and The movable seat 2 is also provided with a first bolt 5, and the shaft portion of the first bolt 5 passes through the first through hole 3 and the second through hole 4 in sequence, and a plurality of groups of first through holes are also arranged on the movable seat 2. The positioning hole 6 is correspondingly provided with a second positioning hole 7 on the fixed seat 1, the first positioning hole 6 and the second positioning hole 7 are aligned one by one, and the movable seat 2 is al...

Embodiment 2

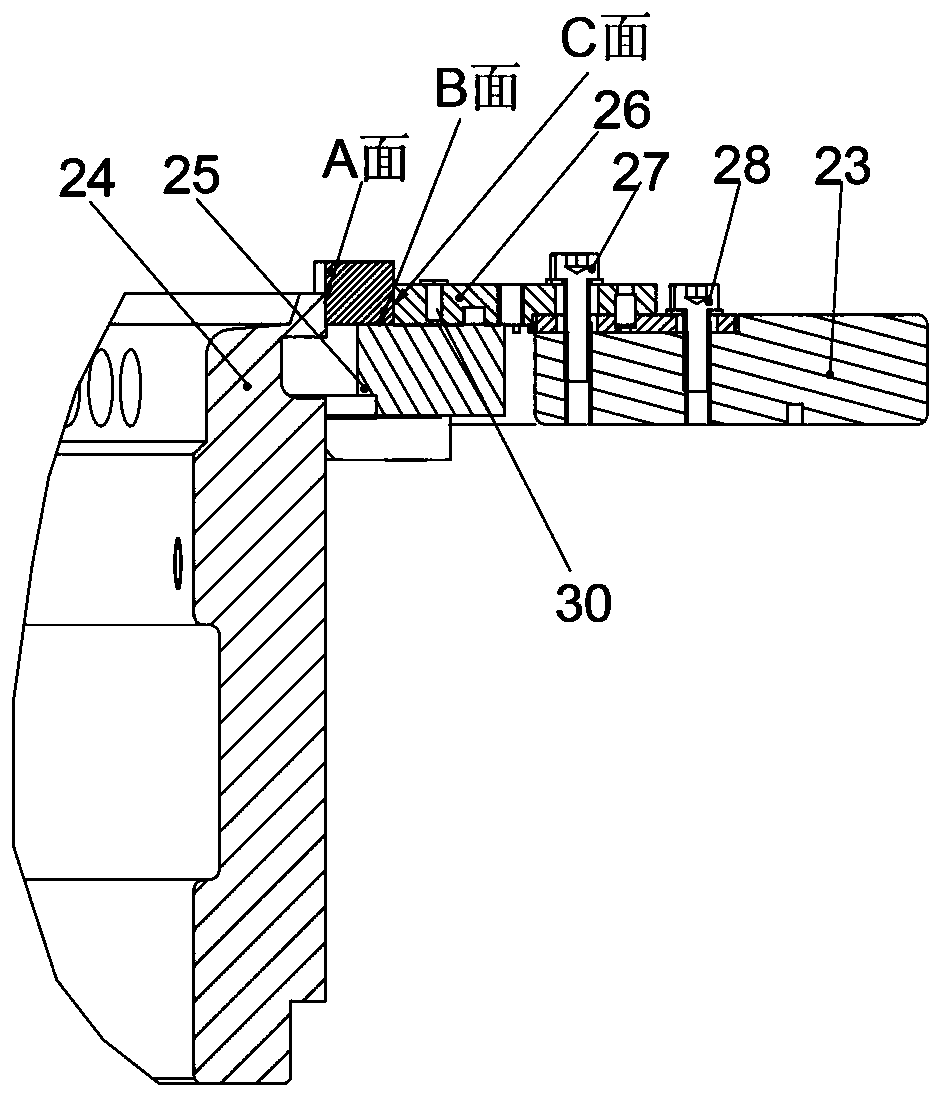

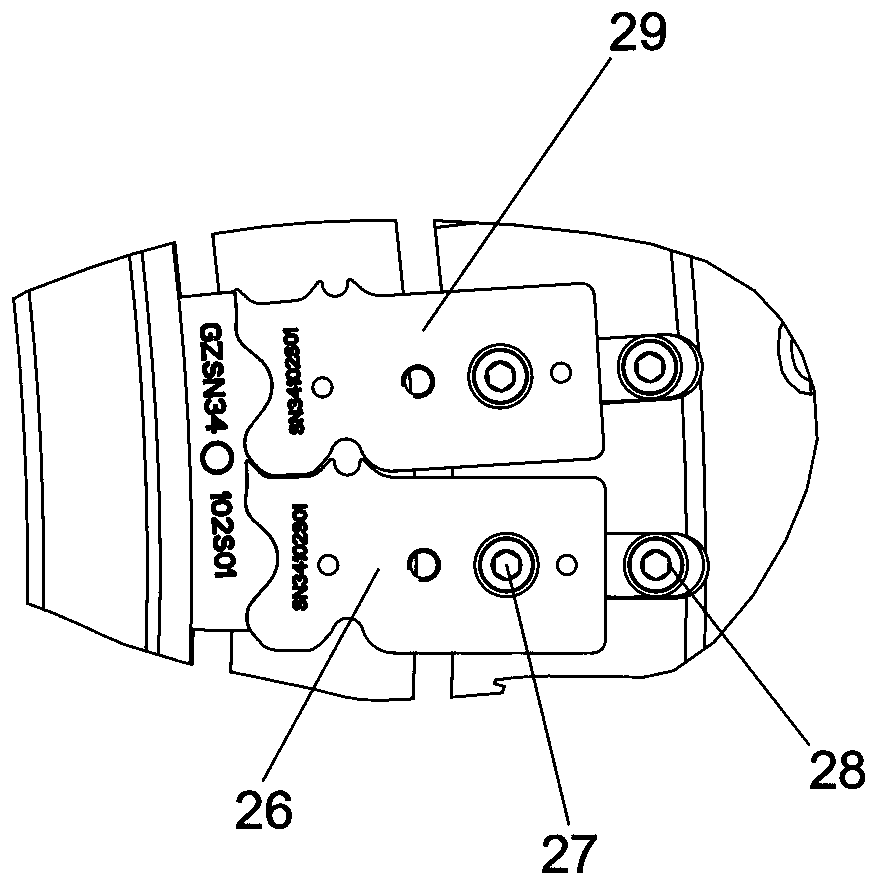

[0039] Please refer to Figure 4-9 The general structure of the sinker triangle adjustment tool for circular knitting machines provided by this embodiment is the same as that of embodiment 1, except that a positioning ring 13 is welded on the first bolt 5, and a positioning ring 13 is installed on the first bolt 5. The shaft portion of the bolt 5 is also provided with a shaft sleeve 14, the shaft sleeve 14 is located above the positioning ring 13, and the bottom surface of the shaft sleeve 14 is in contact with the upper ring surface of the positioning ring 13, and the shaft sleeve 14 is also fixedly sleeved. The transmission gear 15 meshes with the tooth lines on the inner surface of the syringe, and the transmission gear 15 is limited by the positioning ring 13 .

[0040] In this embodiment, a connecting head 16 is integrally formed on the bottom plane of the positioning ring 13. The connecting head 16 is integrally formed by a base 17 and a pillar 18. The pillar 18 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com