Production process tracking management system

A technology of production process and management system, applied in the direction of manufacturing computing system, data processing application, instrument, etc., can solve the problems of not doing the whole roll inspection, partial inspection results, waste of surplus materials, etc., and achieve the effect of effectively commanding production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

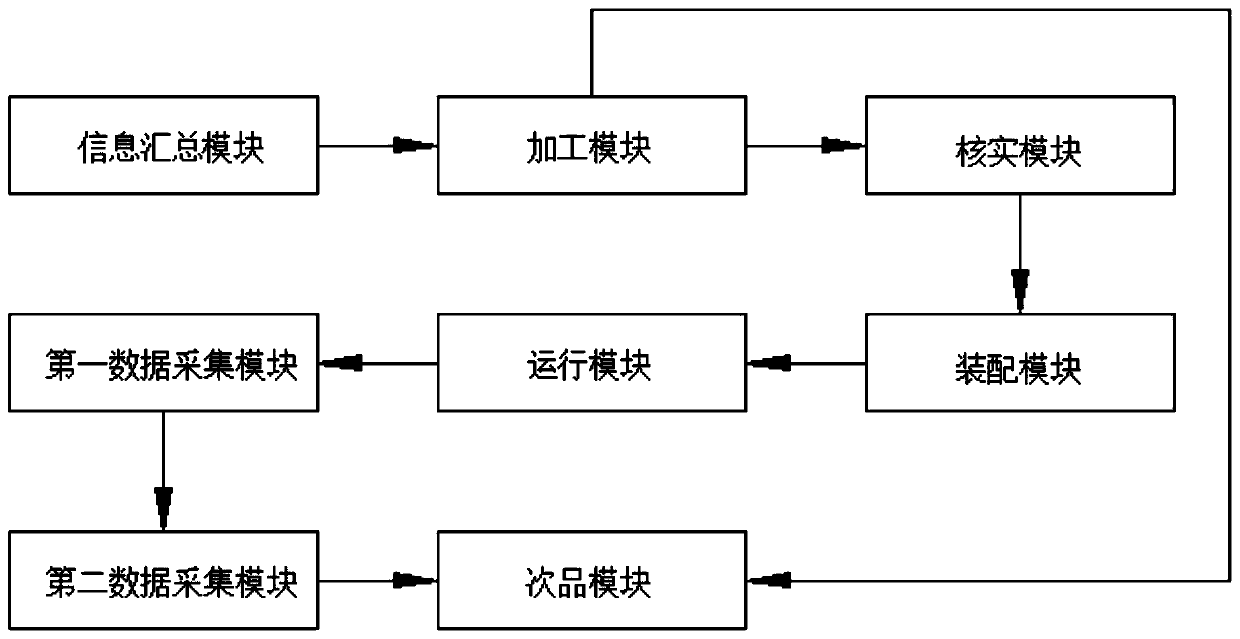

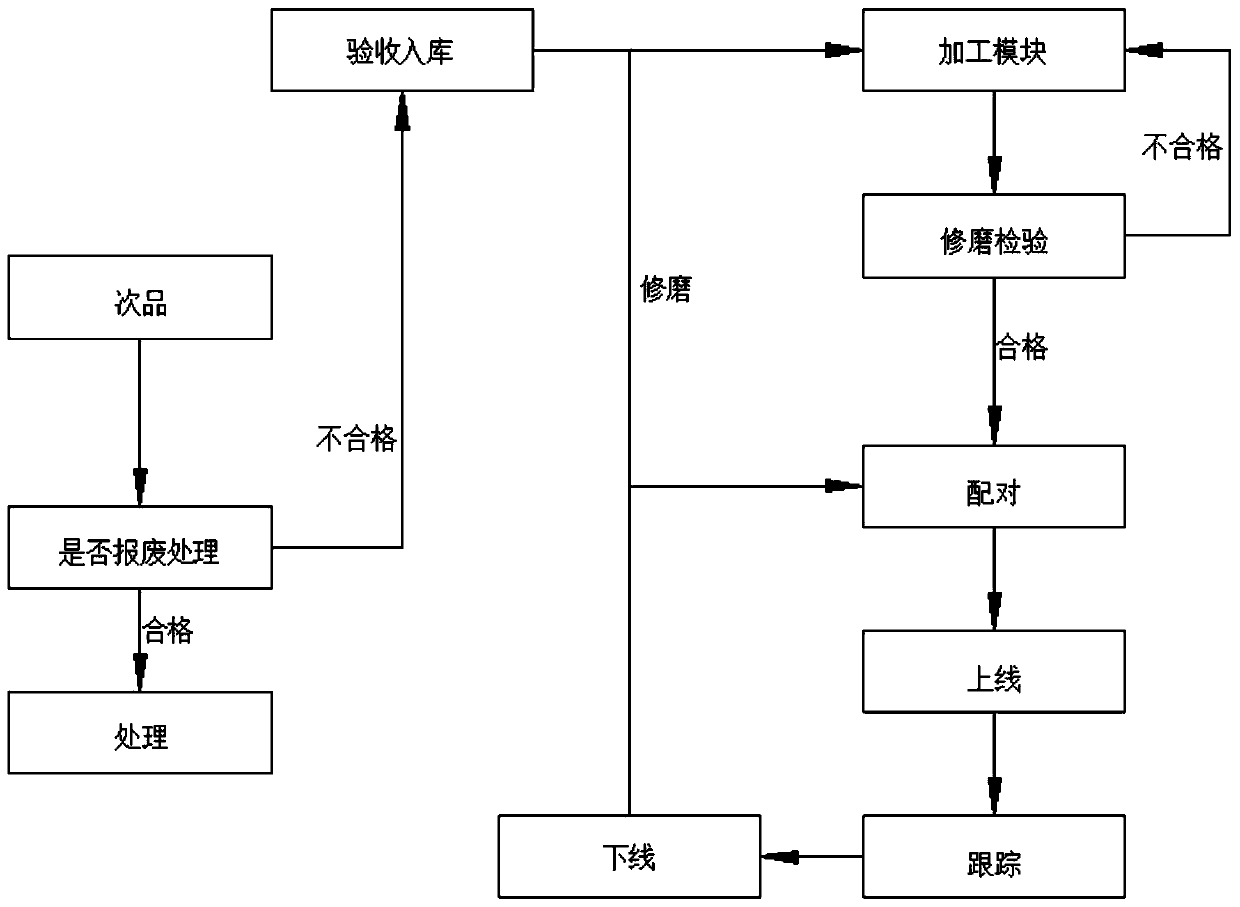

[0029] Embodiment: a kind of production process tracking management system, such as Figure 1-Figure 2 As shown, it includes an information summary module, a processing module, a verification module, an assembly module, an operation module, a first data collection module, a second data collection module, and a defective product module, wherein:

[0030] Information summary module: used to number according to the ex-factory number and actual production of hot-pressed coils, and record factory parameters and information; the information described in the information summary module includes hot-pressed coil grinding results, rolling information after operation, rolling specifications, and cumulative rolled steel information, offline information;

[0031] Processing module: used to record the working parameters of the hot-pressed coil after grinding, preset the assembly frame and information; the information described in the processing module is the assembly frame, rolling line fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com