Method and system for accurately obtaining dry quenching coke burn-out rate

A technology of CDQ and carbon burning, which can solve the problems of low accuracy of carbon burning rate and long cycle by removing certain components, weighing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

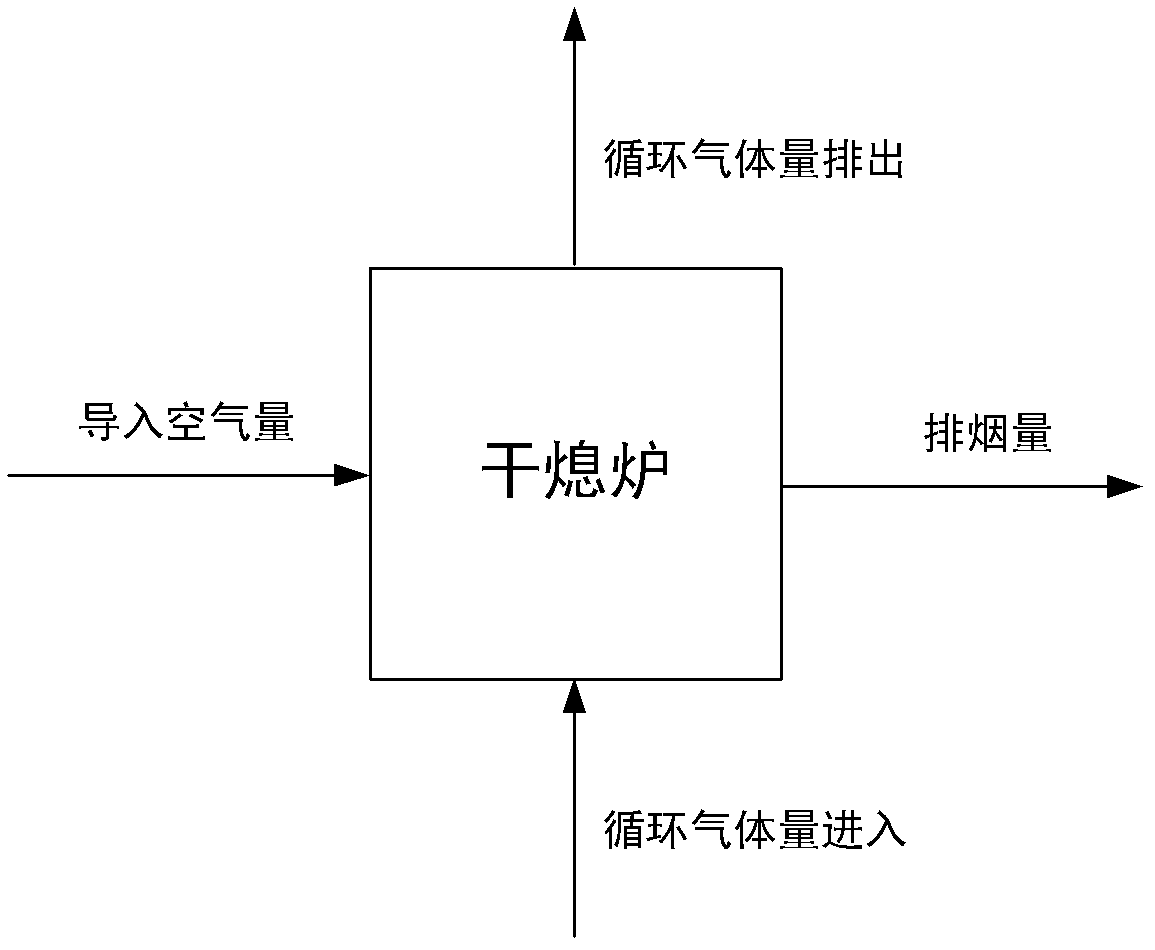

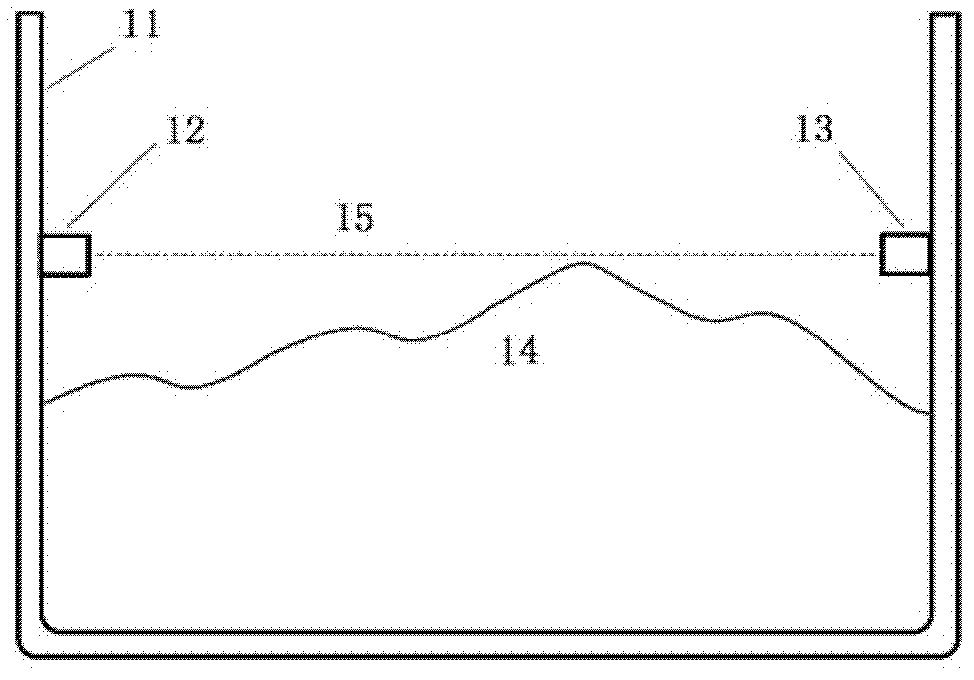

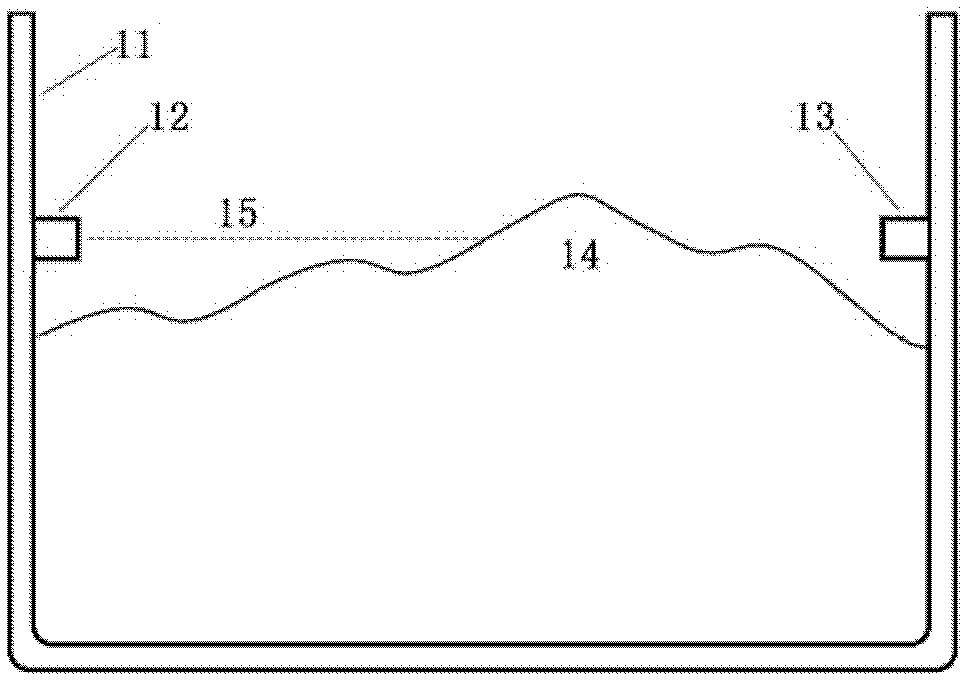

[0089] The method for accurately obtaining CDQ coke burning loss rate of the present invention obtains the interval time T between two adjacent signal connections from the material level detection device usually used in the coke production process of the existing coking industry, and calculates the Coke burning loss within the above interval time T and the amount of red coke charged into the CDQ furnace in the interval time T by formula Obtain the carbon burning loss rate η of CDQ, when the receiver of the material level detection device receives the signal that the signal generator that sends out the signal continuously sends out the signal, it represents that the signal is connected, and the interval time T is the time interval for the material level detection The time interval when the receiver of the device is connected to two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com