Variable-distance suction mechanical arm and operation method

A technology of manipulators and power mechanisms, applied in the field of manipulators, can solve problems such as cumbersome operation process, large changes in parts size, and affect work efficiency, and achieve the effect of changing the suction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

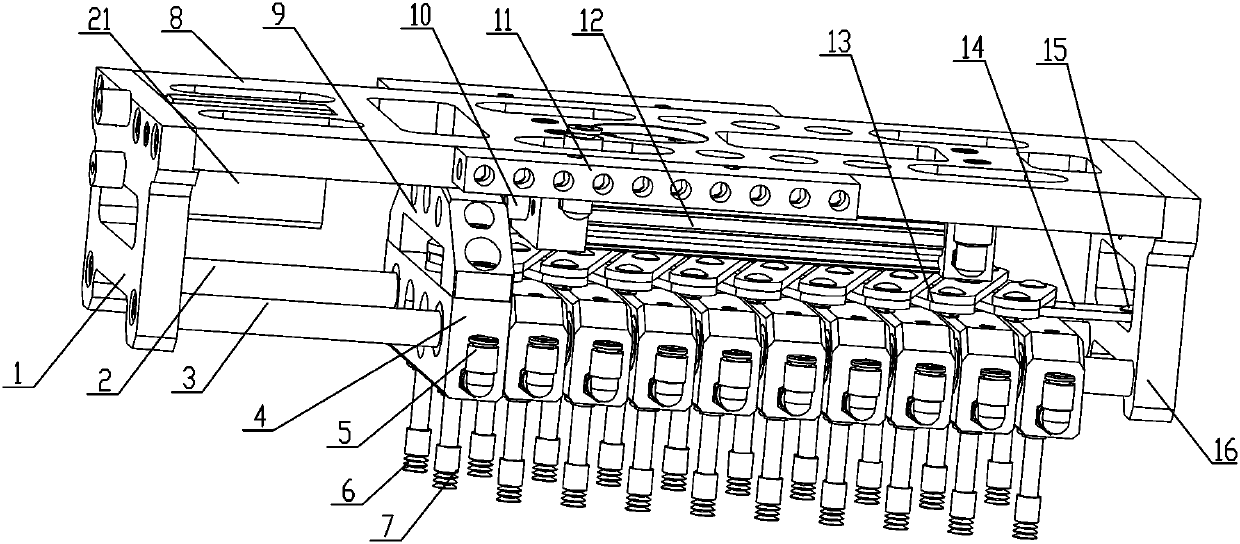

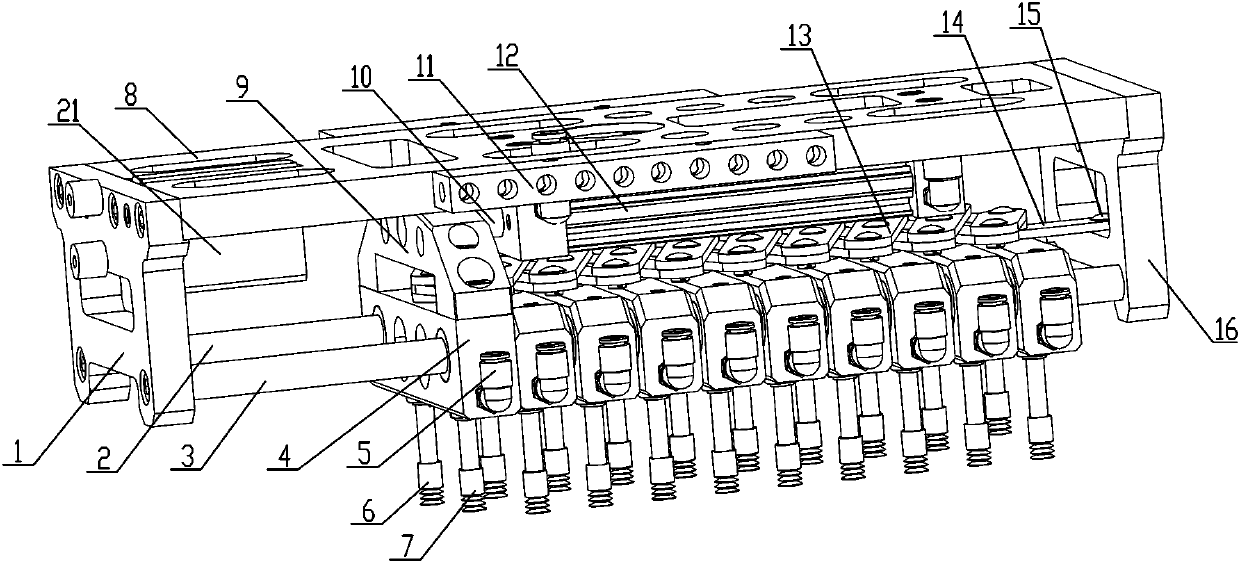

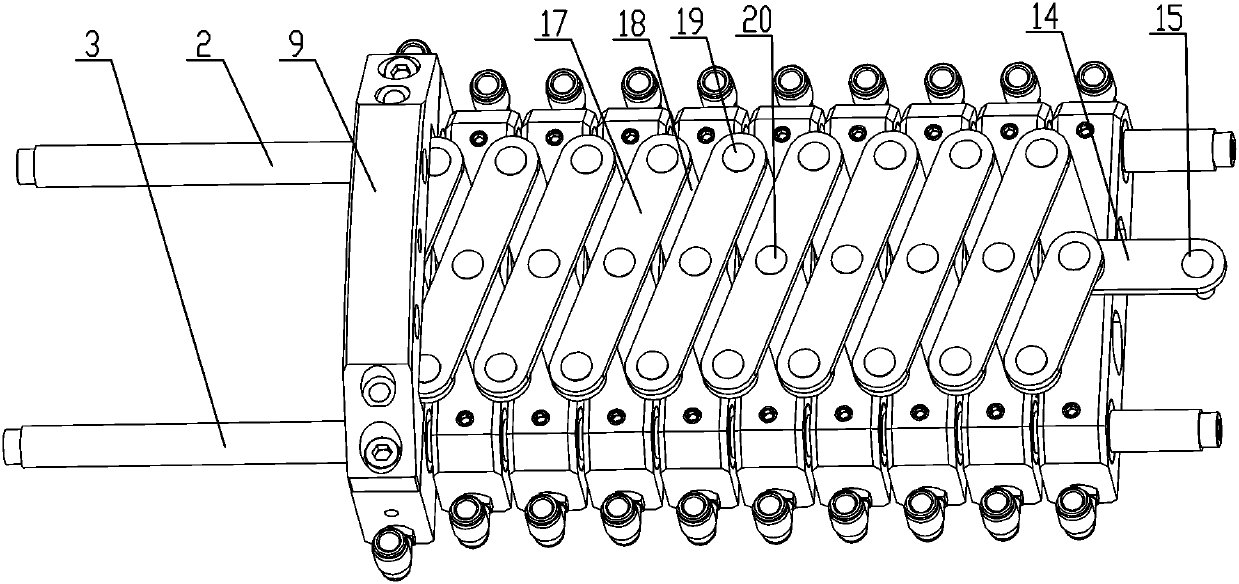

[0026] see Figure 1-4 , a variable-pitch suction manipulator, which includes a top plate 8 for connecting with a handling manipulator, a first side plate 1 and a second side plate 16 are respectively arranged on both sides of the short side of the top plate 8, and the first side plate 1 and the second side plate 16 are fixed in parallel with a first guide rail 2 and a second guide rail 3, and a suction nozzle mounting seat 4 is installed on the first guide rail 2 and the second guide rail 3 in sliding fit, and the suction nozzle mounting seat 4 The bottom of 4 is equipped with a suction structure, and the tops of a plurality of said nozzle mounts 4 are hingedly connected by a stretchable diamond-shaped connecting rod structure 13; a push plate 9 is fixedly installed on the top of a nozzle mount 4 at the farthest position. , the push plate 9 is connected with the power mechanism used to push it to move, and an end connecting plate 14 is hinged on the top of another suction noz...

Embodiment 2

[0033] The operating method of any one of the variable-pitch suction manipulators comprises the following steps:

[0034] Step1: Connect the above-mentioned suction manipulator to the handling manipulator;

[0035] Step2: According to the size of the parts to be absorbed, start the push cylinder 12, and drive the diamond-shaped connecting rod structure 13 to expand and contract by pushing the cylinder 12;

[0036] Step3: The diamond-shaped connecting rod structure 13 drives the corresponding nozzle mount 4 to slide along the first guide rail 2 and the second guide rail 3, changing the distance between two adjacent nozzle mounts 4;

[0037] Step4: Finally, change the distance between the suction nozzles so that it can adapt to the suction of parts of different sizes.

[0038] The use process of the present invention is as follows:

[0039] During use, it is fixedly connected to the handling manipulator at first, then, according to the size of the manipulator, start the push c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com