Special film pasting device for veneer

A film sticking device and plywood technology, which is applied in the direction of packaging, etc., can solve the problems of large changes in plywood thickness and width, unsuitable plywood film, and poor film quality, so as to achieve the effect of improving quality, adjusting stability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

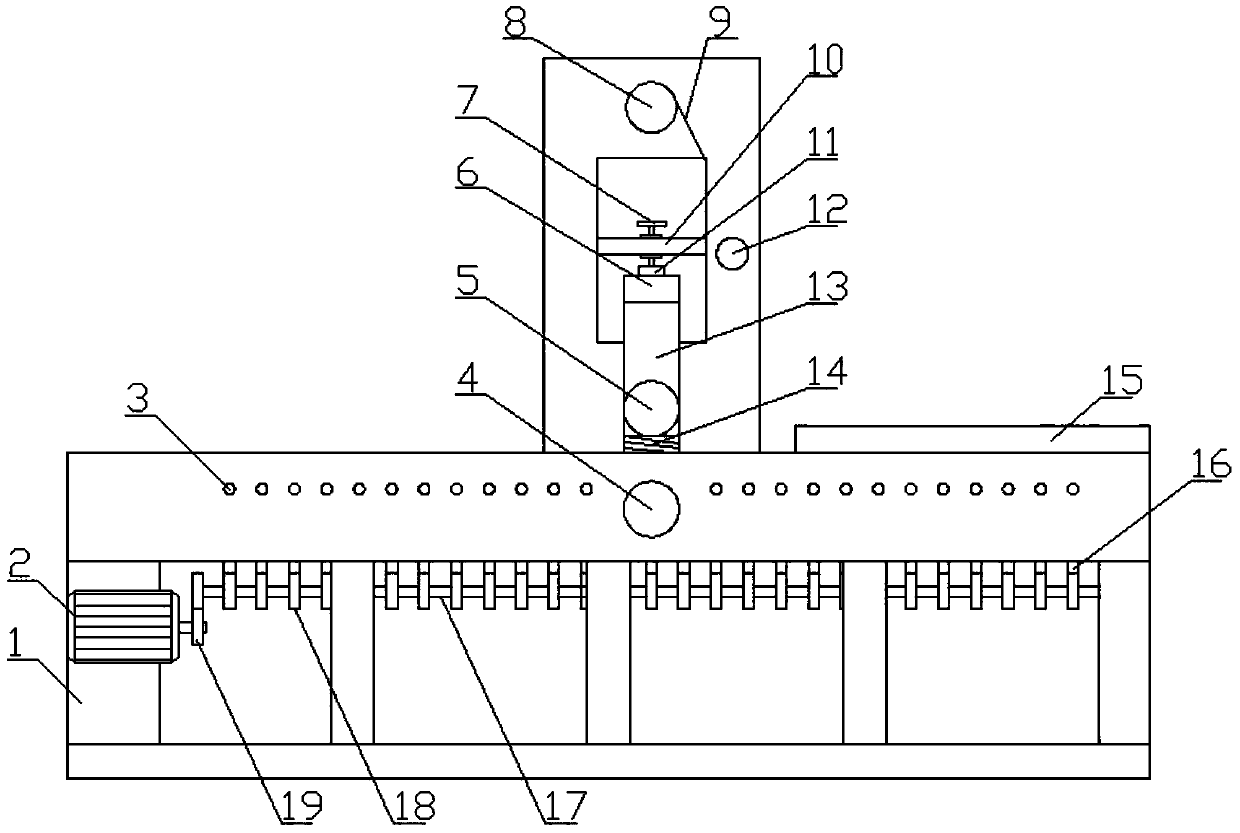

[0041] The film sticking device dedicated to plywood in this embodiment includes a frame, on which a conveying roller composed of a plurality of rollers is arranged, and the conveying roller is driven to rotate by a drive motor, and a film sticking mechanism is provided on the said frame, The film sticking mechanism includes a coiling roll wound with a film, a tension roll for dredging the film, an upper film sticking roll and a lower film sticking roll, the upper film sticking roll is positioned above the lower film sticking roll, and the gap between the film sticking rolls Compatible with the thickness of the plywood, the upper laminating roller is provided with an adjusting device for adjusting the distance between the upper laminating roller and the lower laminating roller.

Embodiment 2

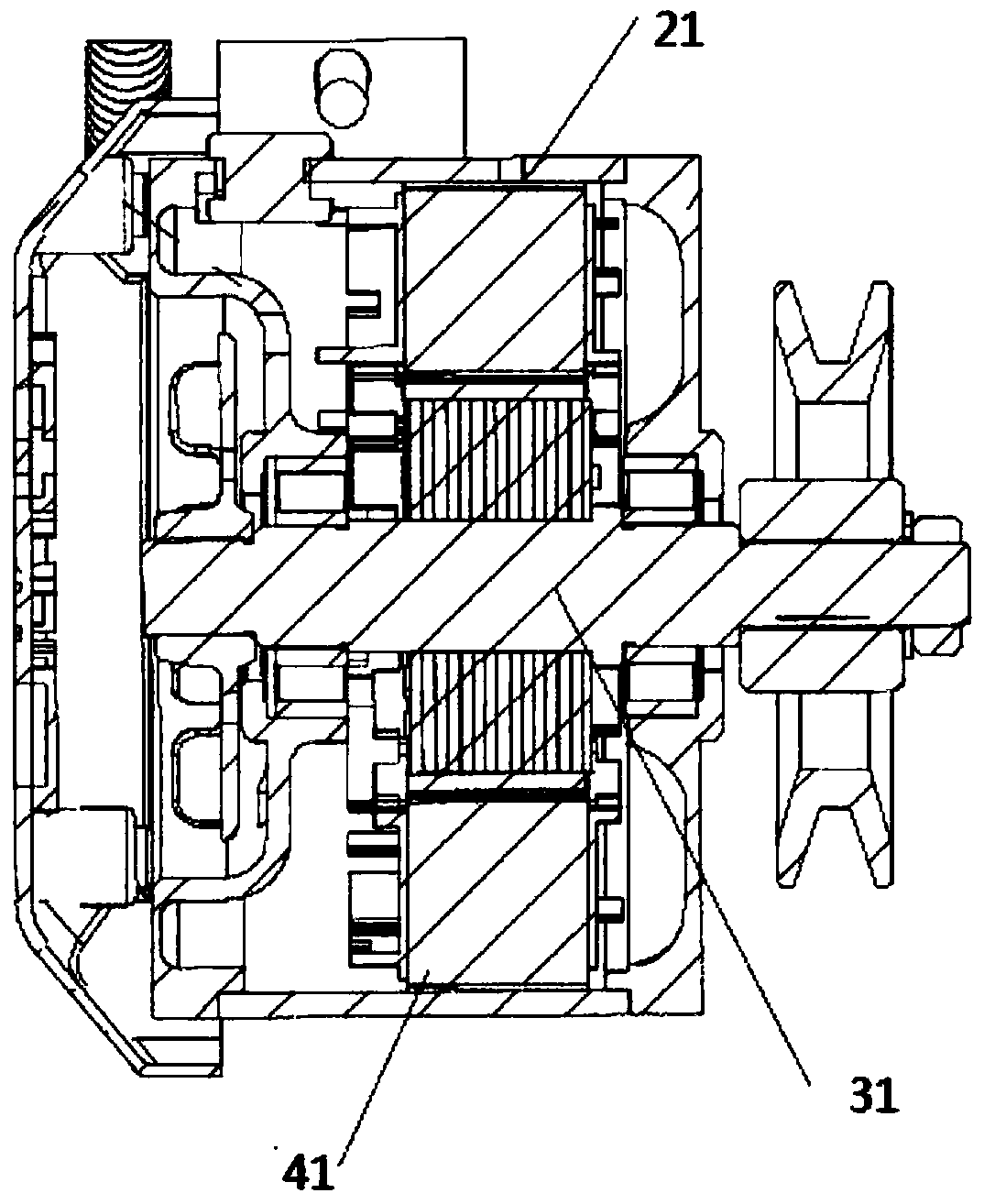

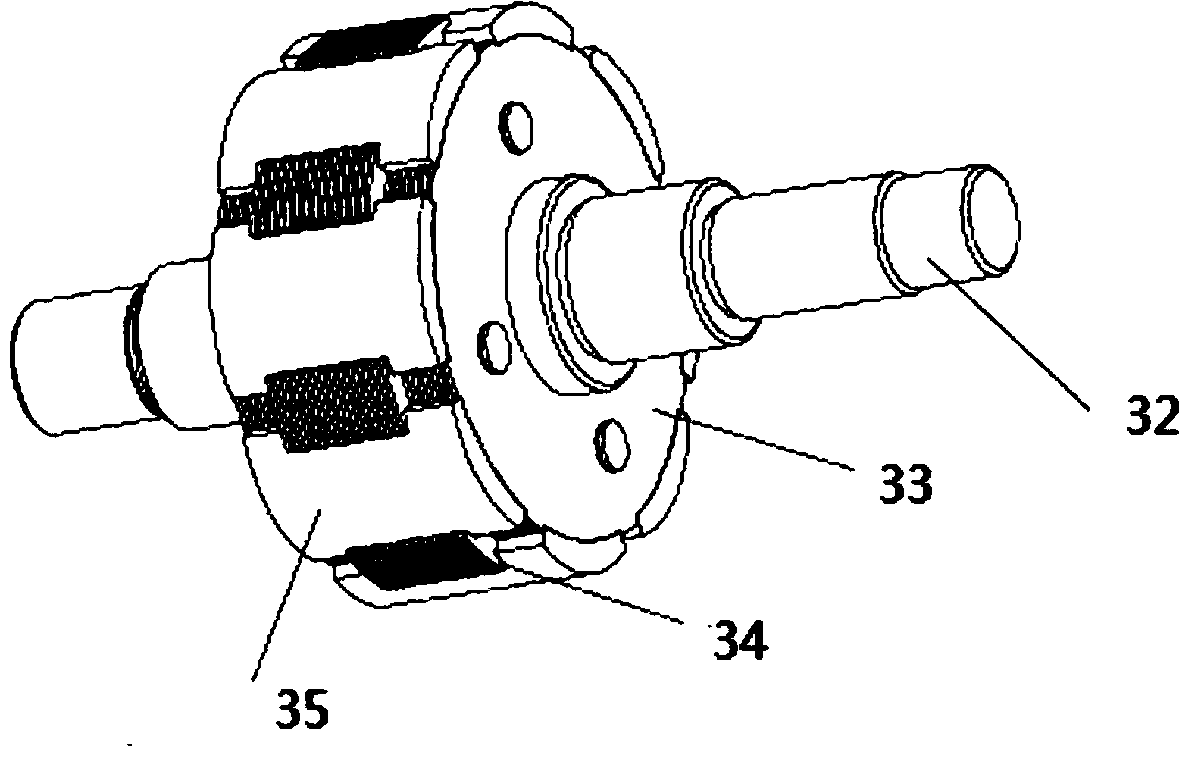

[0043] The film sticking device dedicated to plywood in this embodiment includes a frame, on which a conveying roller composed of a plurality of rollers is arranged, and the conveying roller is driven to rotate by a drive motor, and a film sticking mechanism is provided on the said frame, The film sticking mechanism includes a coiling roll wound with a film, a tension roll for dredging the film, an upper film sticking roll and a lower film sticking roll, the upper film sticking roll is positioned above the lower film sticking roll, and the gap between the film sticking rolls Adapting to the thickness of the plywood, the upper film lamination roller is provided with an adjustment device for adjusting the distance between the upper film lamination roller and the lower film lamination roller; The bearing jacket is provided with a slider, and the slider is adapted to the chute arranged on the frame; the sliders at both ends of the frame are connected as a whole through connecting r...

Embodiment 3

[0045] The film sticking device dedicated to plywood in this embodiment includes a frame, on which a conveying roller composed of a plurality of rollers is arranged, and the conveying roller is driven to rotate by a drive motor, and a film sticking mechanism is provided on the said frame, The film sticking mechanism includes a coiling roll wound with a film, a tension roll for dredging the film, an upper film sticking roll and a lower film sticking roll, the upper film sticking roll is positioned above the lower film sticking roll, and the gap between the film sticking rolls Adapting to the thickness of the plywood, the upper film lamination roller is provided with an adjustment device for adjusting the distance between the upper film lamination roller and the lower film lamination roller; The bearing jacket is provided with a slider, and the slider is adapted to the chute arranged on the frame; the sliders at both ends of the frame are connected as a whole through connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com