A method to increase the number of disassembly and assembly of threaded holes of alsic parts

A technology of threaded holes and times, applied in the direction of threaded fasteners, nuts, connecting components, etc., can solve the problems of many times of use, low strength of aluminum materials, threaded sleeves falling off or slipping out, etc., to achieve tight bonding and reliable use. High, high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

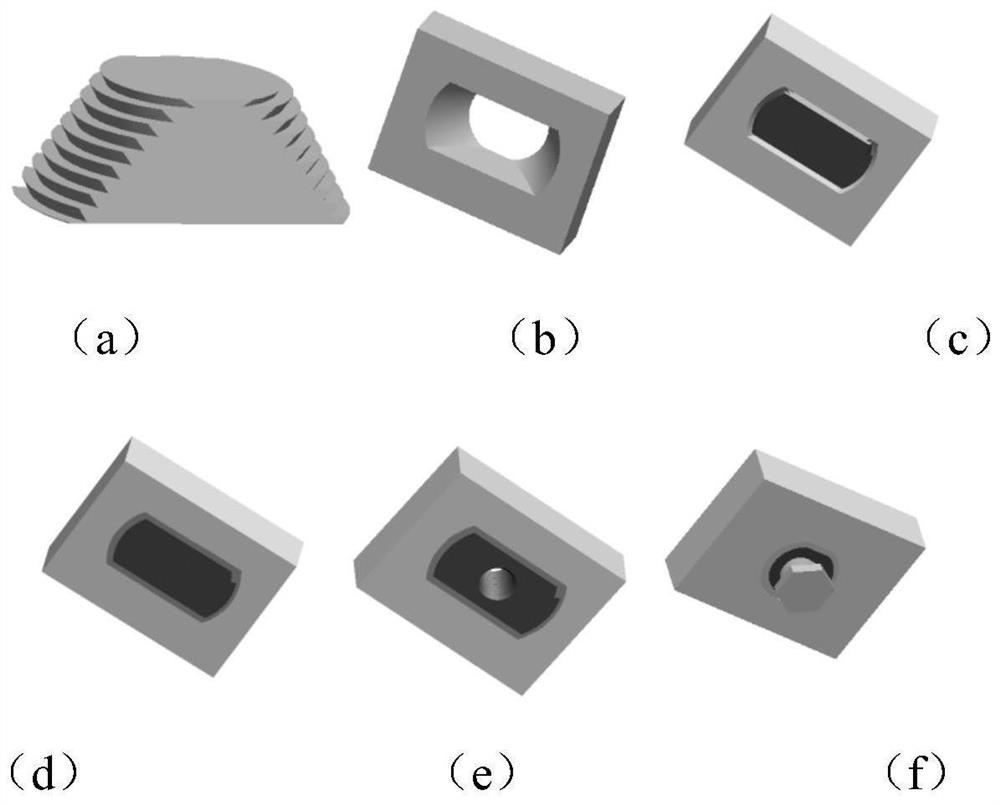

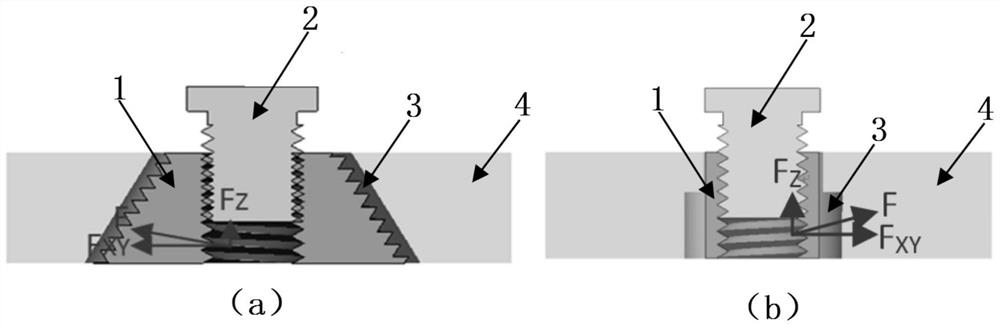

[0040] A method to increase the number of disassembly and assembly of threaded holes of AlSiC parts. When processing titanium alloy inserts, the structure of the inserts is as follows figure 1 As shown in (a), the shape is conical, with a taper of 6°, which limits its degree of freedom in the Z-axis direction. A plane is reserved on the side to limit its degree of freedom in the XY direction. Partial teeth are reserved on the side to ensure its mechanical locking with aluminum.

[0041] The minimum size of the small head of the inlay is 5mm, and the pre-tapping thread cannot exceed M3 to ensure that the thread structure is on the inlay.

[0042] When processing silicon carbide ceramics, a reserved hole is reserved in advance, and the shape of the inner hole is consistent with the shape of the insert, such as figure 1 As shown in (b), ensure that the matching gap between the inlay and the ceramic reserved hole is 0mm.

[0043] Then the mold is impregnated. During the mold load...

Embodiment 2

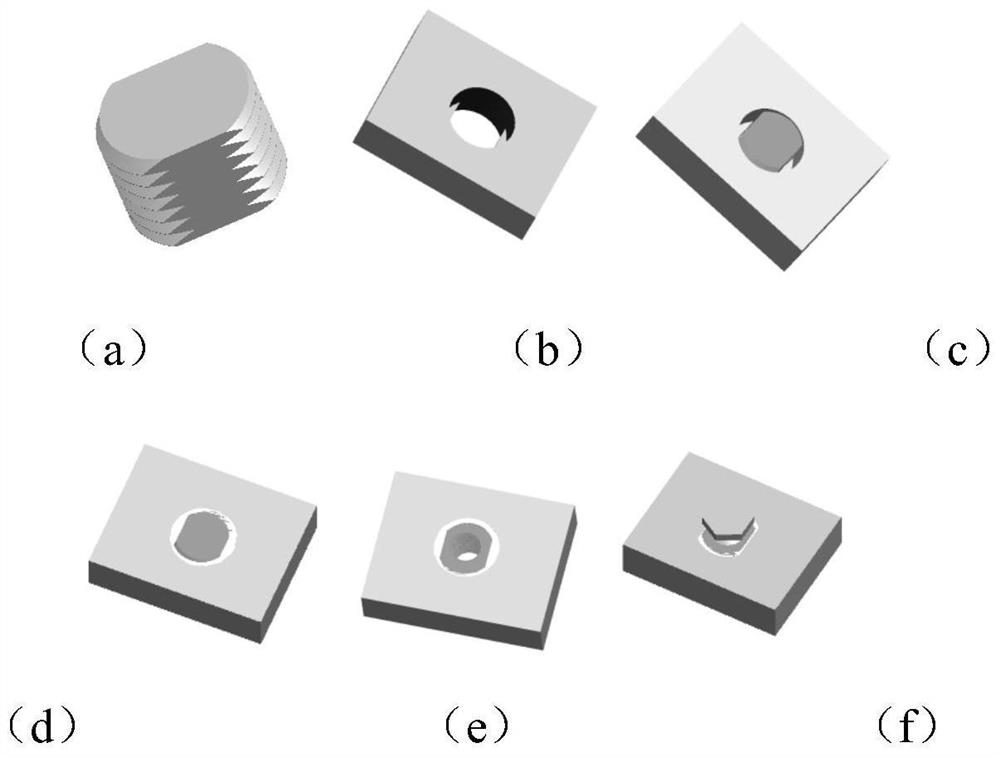

[0046]The principle of this embodiment is the same as that of Embodiment 2, except that the structures of the holes reserved for the mosaic piece and the silicon carbide green body are changed. In this embodiment, when processing the titanium alloy insert, the insert structure is as follows figure 2 As shown in (a), the shape is wedge-shaped, which restricts its degree of freedom in the Z-axis direction. A plane is reserved on the side to limit its degree of freedom in the XY direction. Partial teeth are reserved on the side to ensure that it is mechanically locked with aluminum. The outer diameter of the small head of the insert is 5mm, and the pre-tapping thread cannot exceed M3 to ensure that the thread structure is on the insert.

[0047] When processing silicon carbide ceramics, a reserved hole is reserved in advance, and the shape of the inner hole is consistent with the shape of the insert, such as figure 2 As shown in (b), ensure that the matching gap between the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com