Bearing bush separation clamp

A technology for bearing bushings and bushings, which is applied to bearing-related force sensors, force/torque/power measuring instruments, measuring devices, etc., and can solve the problem of difficult axial pull-out and circumferential rotation loosening of bushings. test, the inability to realize the torsion torque test of the bushing separation, and the difficulty in meeting the test requirements of the bushing loosening experiment, etc., to achieve the effect of high test reliability, easy installation and disassembly, and easy take-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0024] This embodiment provides a jig for separating the bearing bush. Using the jig to separate the bearing bush from the outer ring can not only ensure the reliable separation of the bush from the outer ring of the bearing, but also ensure the interference between the bush and the outer ring of the bearing. Coordinated loosening torque and pull-out force are tested.

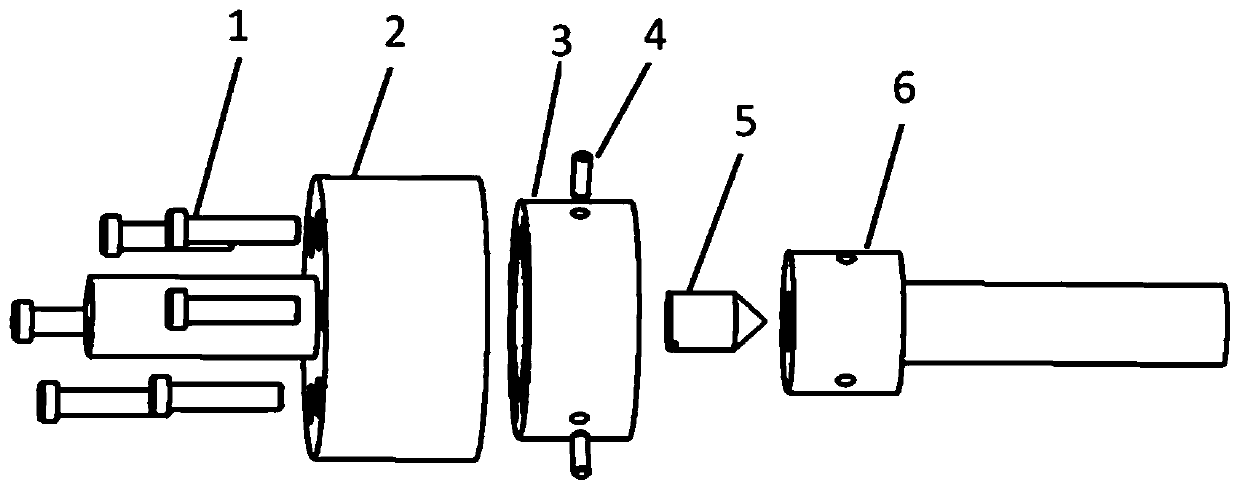

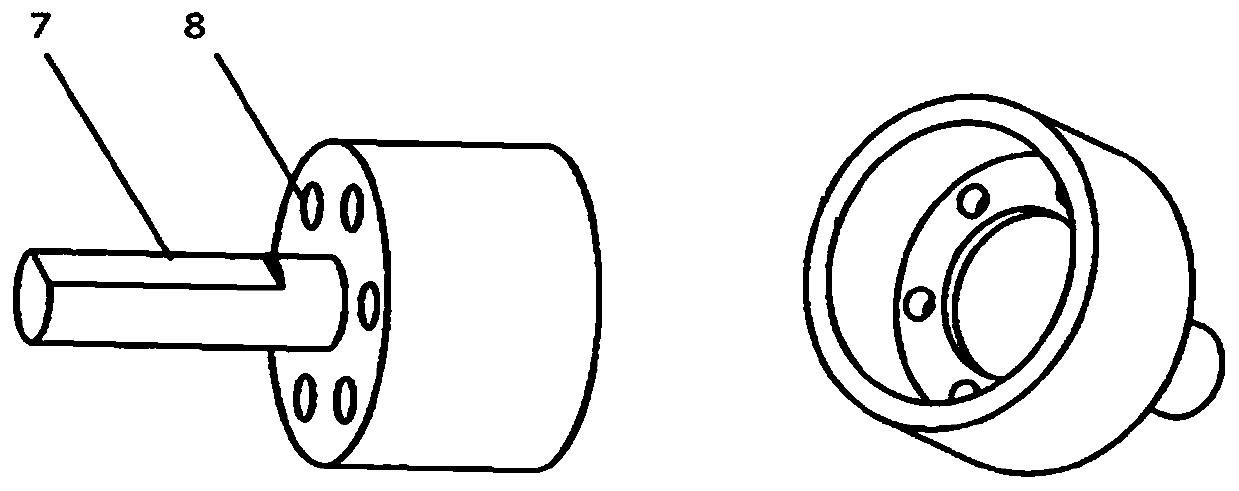

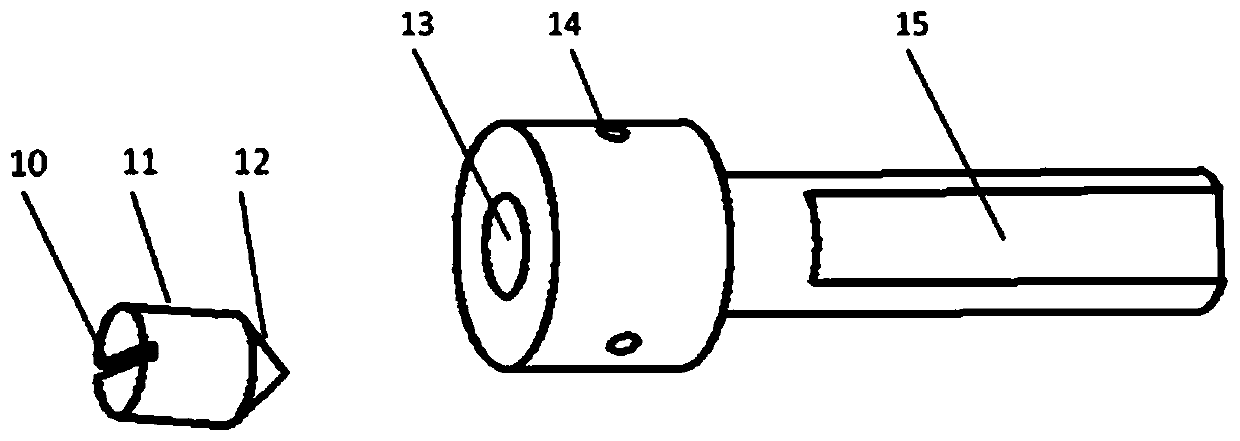

[0025] Such as Figure 1-Figure 4 As shown, the bearing bush separation jig includes: a bearing outer ring mounting seat 2 and a bushing mounting seat 6 . Among them, the bearing outer ring mounting seat 2 is a hollow sleeve with one end open and one end closed. The outer end surface of the closed end is provided with a clamping rod A7, and a plurality of bolt holes 8 are processed on the closed end surface. The test bearing 3 to be separated The coaxial sleeve is installed in the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com