Tile moulding process

A molding process and ceramic chip technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost of mold customization, inability to meet small batch production, long waiting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

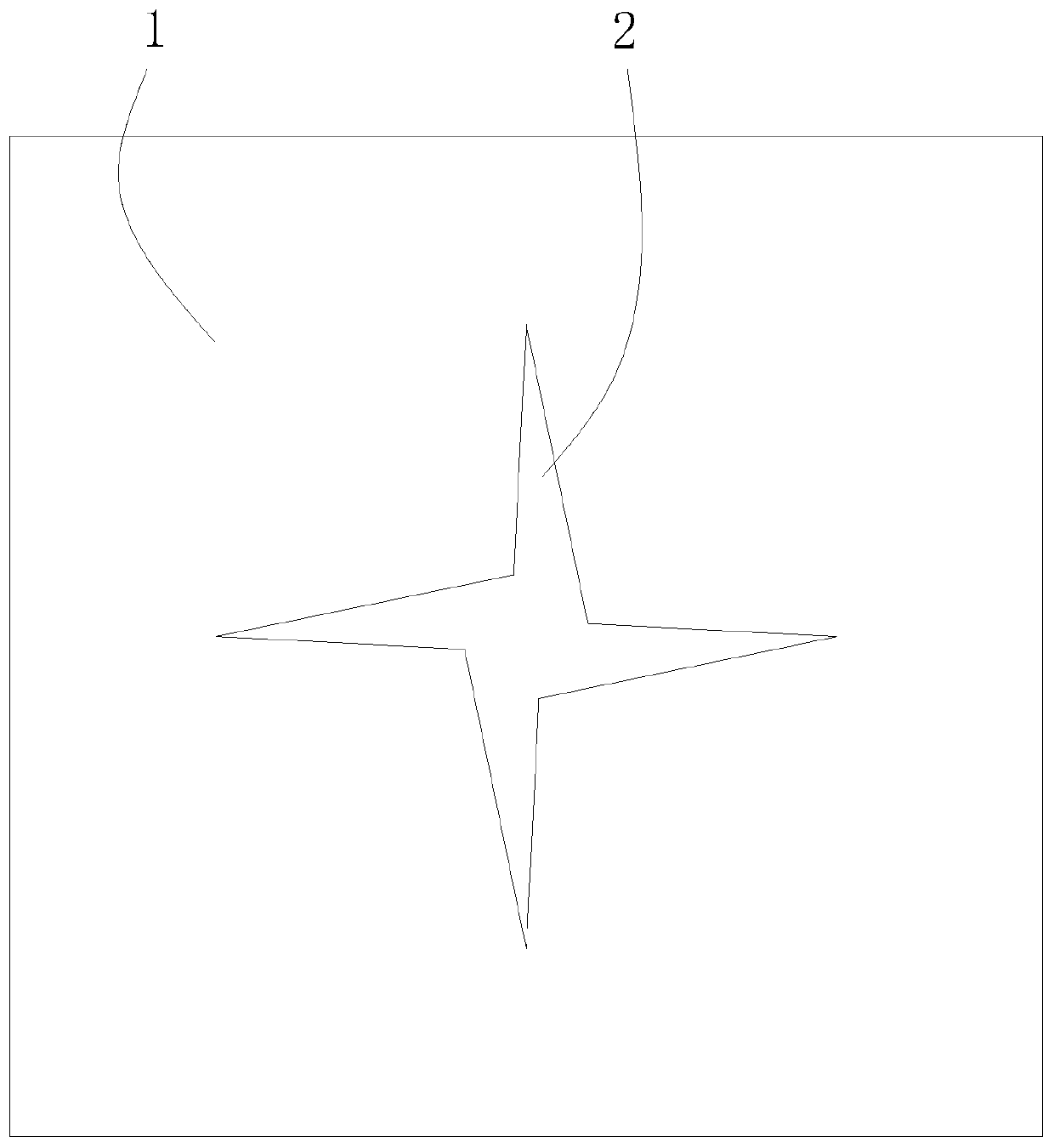

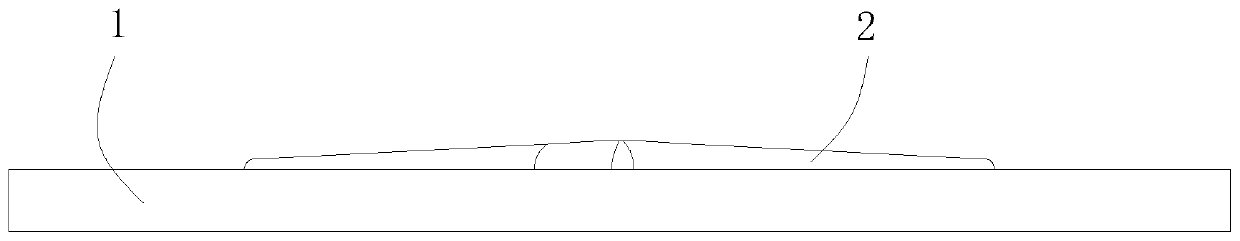

[0026] A ceramic chip molding process, comprising the following steps:

[0027] a: Design the pattern to be printed, and design the raised position on the tile according to the pattern, and make the screen according to the raised position.

[0028] b: Purchasing or pressing to make ordinary flat adobes, that is, ordinary adobes formed by pressing mud, and the pressed mold does not have a pattern.

[0029] c: Select the ordinary planar adobe produced in step b, determine the position to be raised according to step a, and pile up the frit for the first time on the position where the protrusion is to be made. The frit is a kind of glass particles, and the frit pile will be connected into a piece of glass that is tightly combined with the brick body after firing. In the operation of stacking frits, a distributing machine is used to distribute frits, and the wire mesh made in step a is loaded into the distributing machine, and the distributing machine distributes frits according t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap