Negative pressure type dust suction electric drill

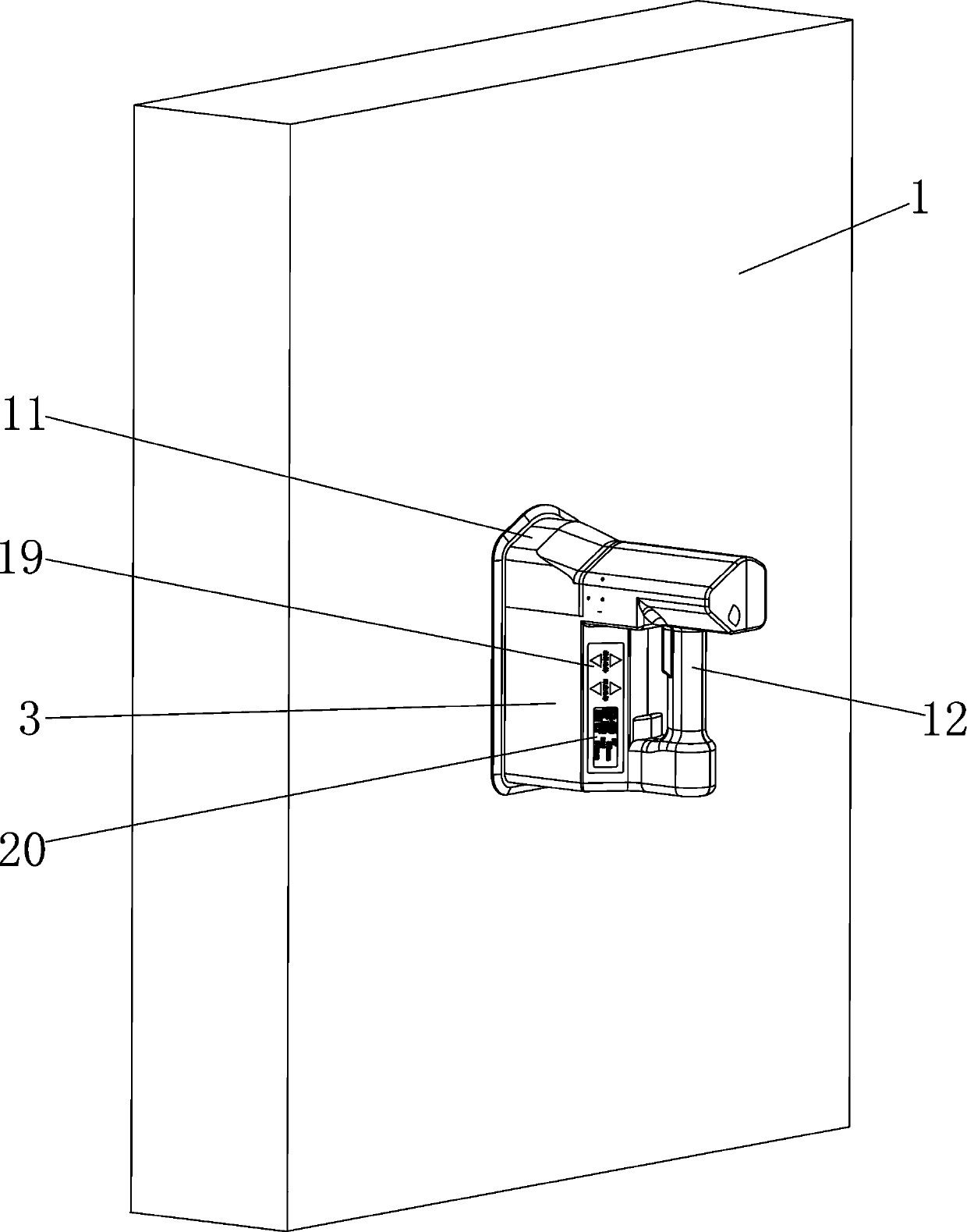

A negative pressure, electric drill technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of low practical feasibility, difficult to grasp the strength of the afterburner, and high center of gravity of the electric drill, and achieves enhanced ease of fixation, enhanced The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the first embodiment, the electric drill body 3 is also provided with a power cord to connect with an external power source, or it may be directly powered by a built-in battery. In the second embodiment, the power cord is integrated with the vacuum pipe 23 to simplify the wiring.

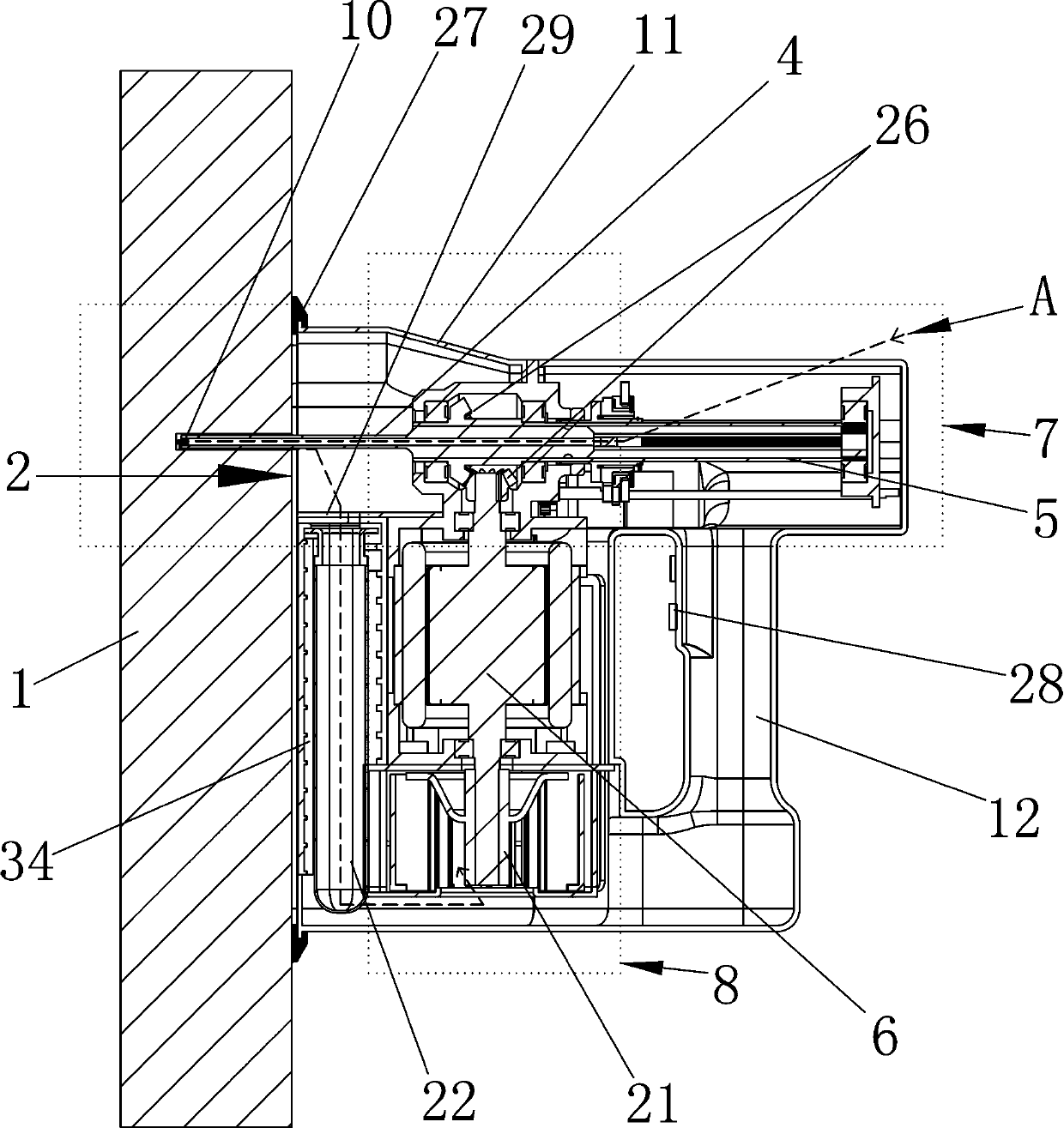

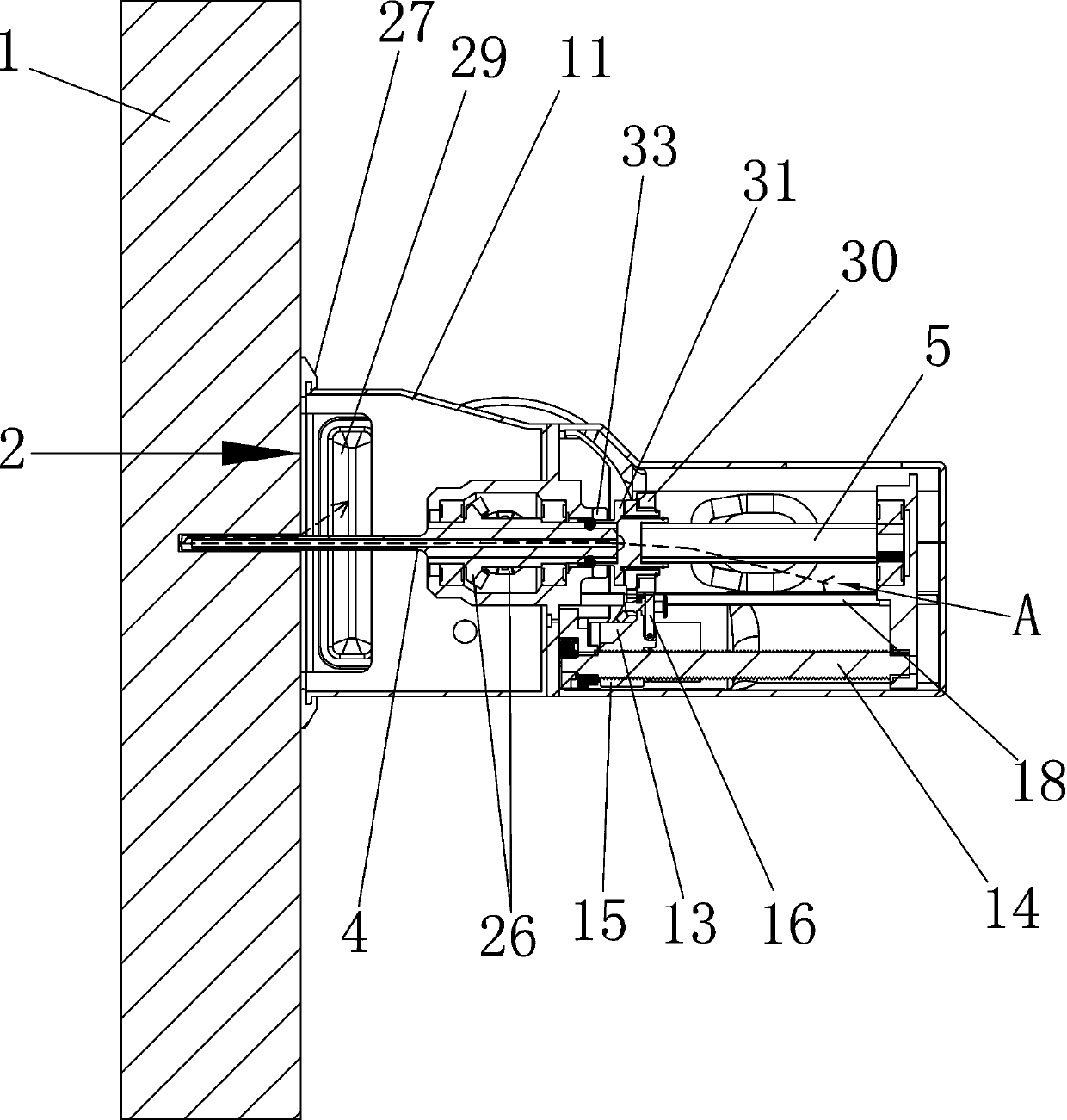

[0044] The working principle of the present invention:

[0045] 1. Lower the center of gravity of the electric drill, use the double-headed motor 6 as a part of the machine base, and connect it with the negative pressure cover 11. When the double-headed motor 6 or the vacuum cleaner starts up, the negative pressure cover 11 will suck the whole electric drill on the wall together. The purpose of this is to greatly enhance the easy fixability of the whole electric drill.

[0046] 2. Install the multi-faceted angle shank drill bit 10 in the drill bit 10 casing 5, the motor drives the casing 5 to rotate through the angle teeth, and the casing 5 drives the drill bit 10 to rotate. The casing 5 is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com