Semi-axle sleeve for automobile

A half-shaft casing and automobile technology, applied in the field of spare parts, can solve the problems of loose connection thread, accidental injury to the driver, casing deformation and damage, etc., achieve good connection, solve loosening or falling off, and reduce unnecessary effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

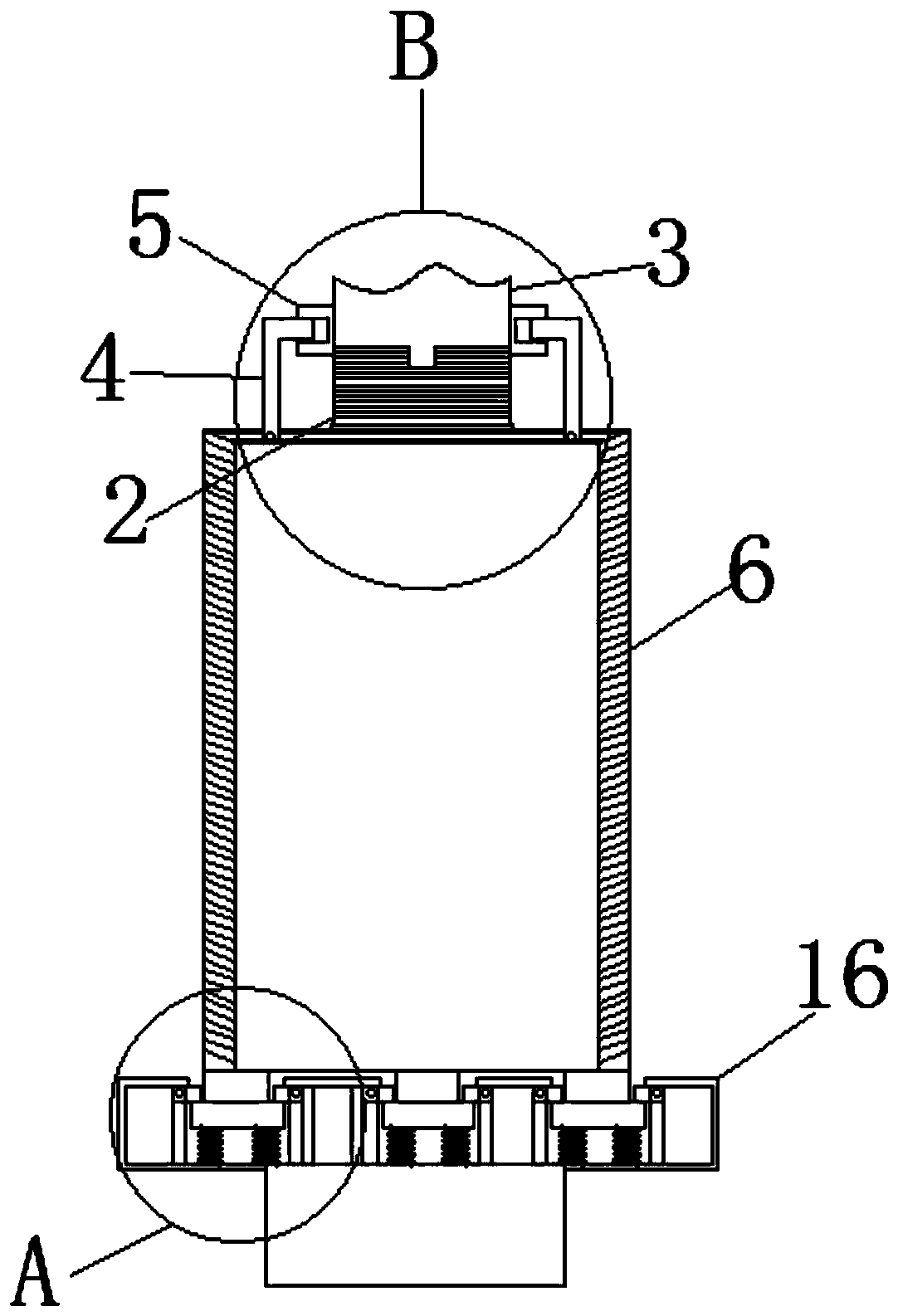

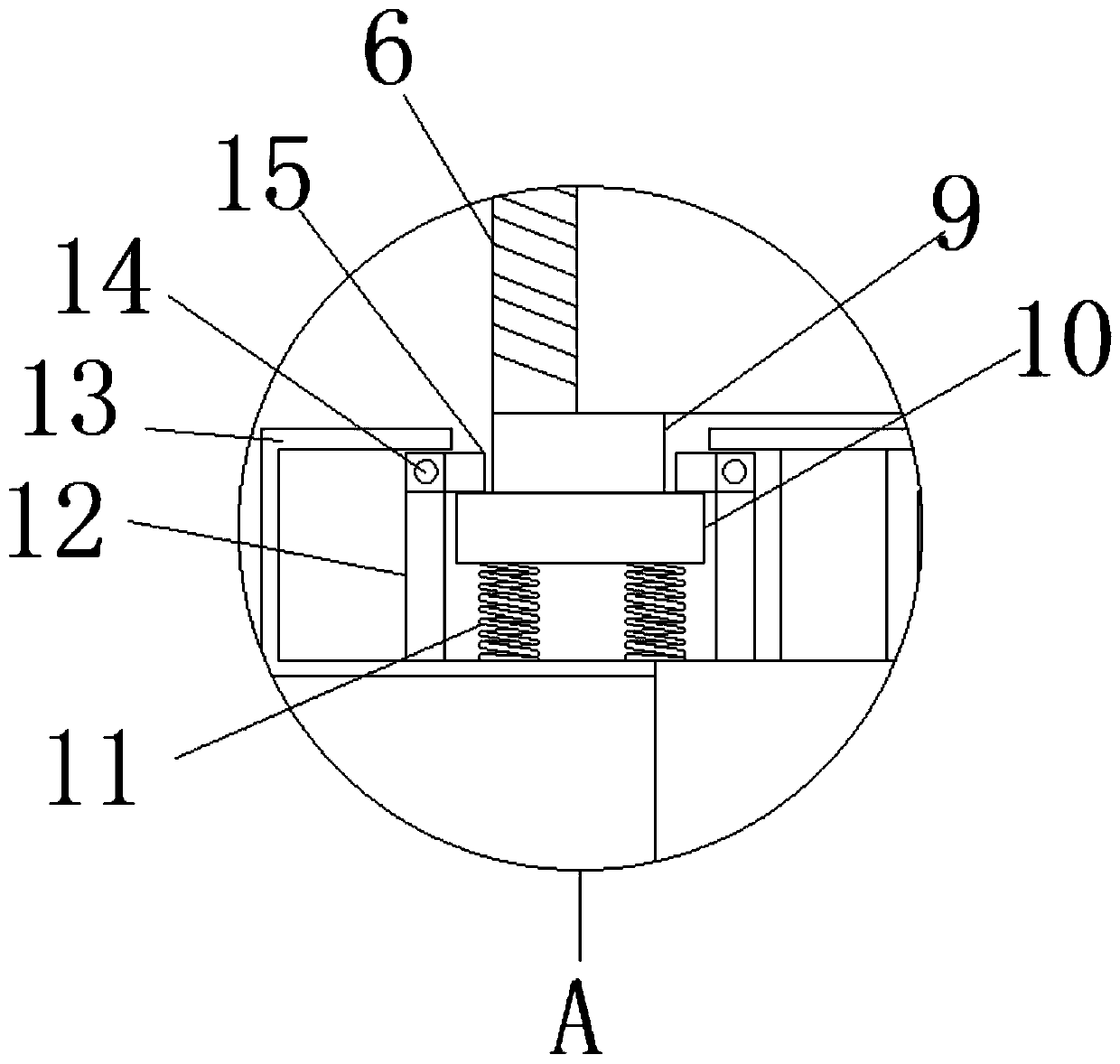

[0023] see Figure 1-Figure 5 , the present invention provides a technical solution: a semi-axis bushing for automobiles, including a bushing frame 1, a bearing ring 16 is installed at the lower end of the bushing frame 1, and a pressure dividing device is set on the periphery of the bushing frame 1. The pressure device comprises a decompression tube 6, a connecting rod 9, a locking block 10, a spring 11, a fixed rod 12, a limit rod 13, a rotating shaft 14 and a rotating block 15, and the connecting rod 9 is installed at the lower end around the decompression tube 6, The clamping block 10 is installed on the lower end of the connecting rod 9, the spring 11 is installed on both sides of the lower end of the clamping block 10, the fixed rod 12 and the rotating block 15 are rotatably connected by the rotating shaft 14, and the limit rod 13 is installed on one side of the bearing ring 16. At the upper end of the side, the rotating shaft 14 is installed at the junction of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com