Device for punching and cutting sucking disc part of electromagnetic clutch

An electromagnetic clutch and sucker technology, applied in the field of stamping dies, can solve problems such as difficult material removal, product outer diameter expansion, large material flow, etc., to achieve the effects of avoiding material flow, easy unloading, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

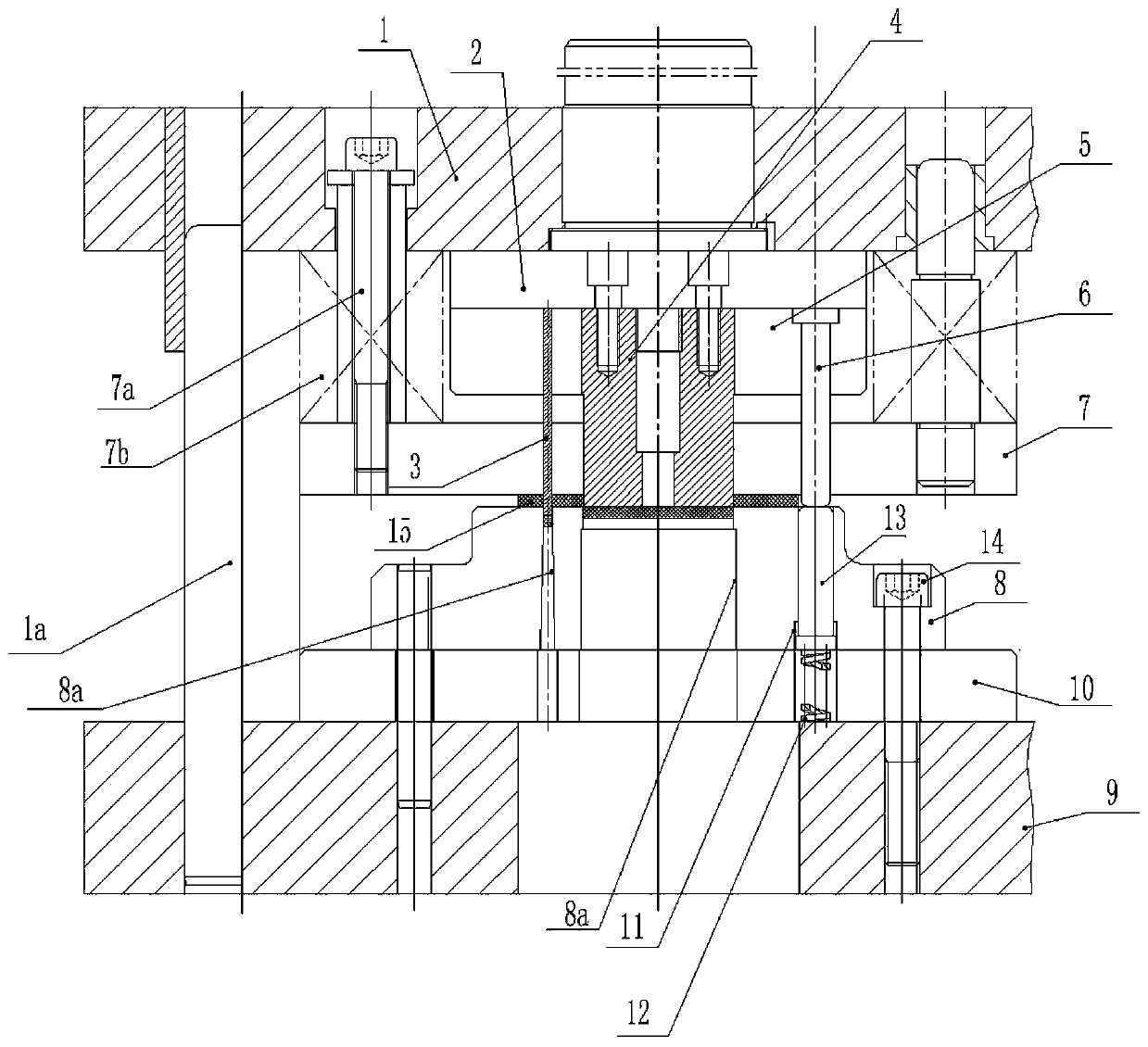

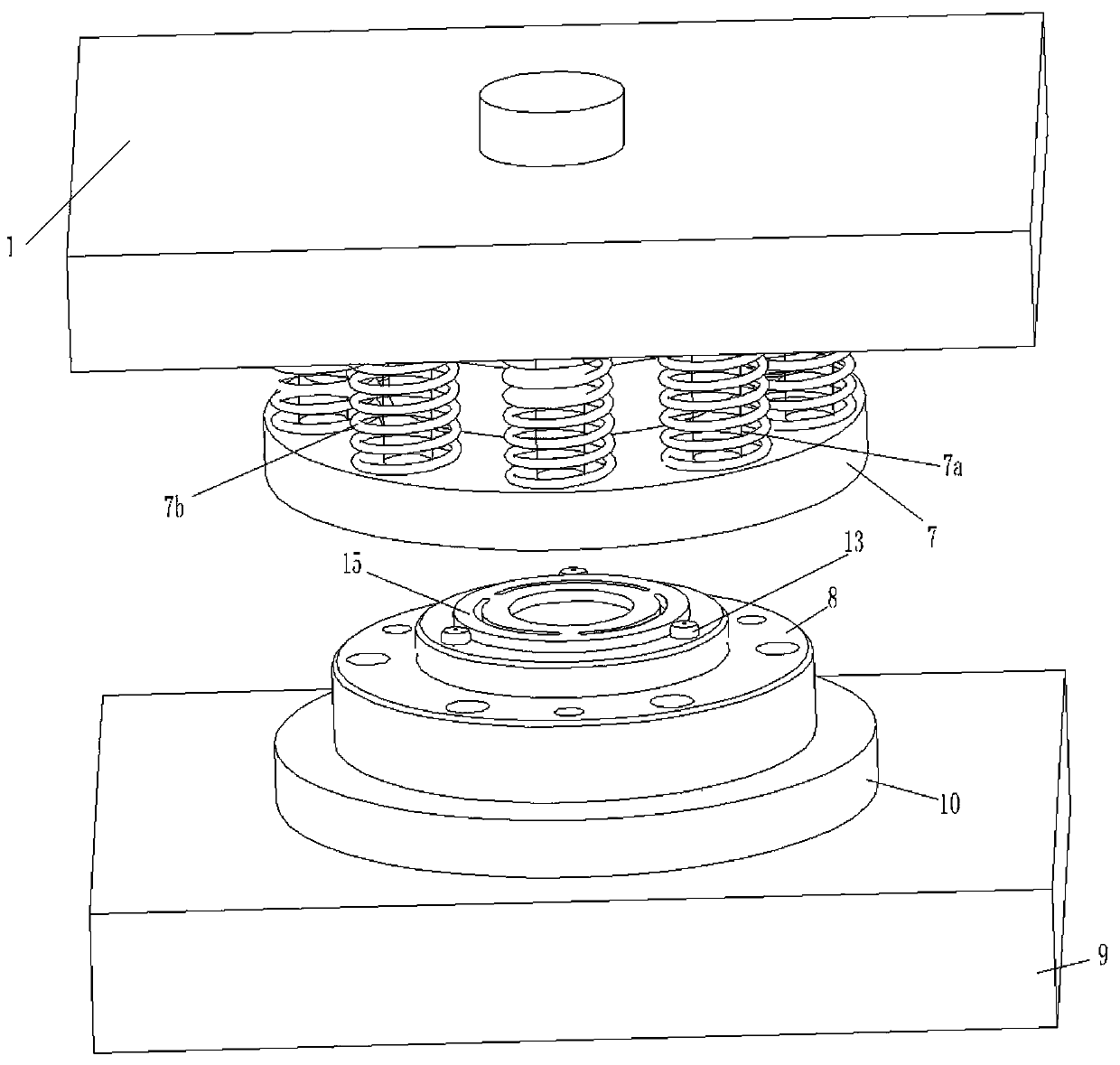

[0019] Such as figure 1 , 2 As shown, it includes an upper mold part and a lower mold part corresponding to each other. The upper mold part includes an upper template 1, an upper backing plate 2, and a coaxially distributed punch 4 is connected to the upper backing plate 2 by bolts, and the punch 4 is cylindrical. The upper backing plate 2 on the outside of the punch 4 is welded with a punch 3 whose lower end face is waist-shaped, and the upper backing plate 2 is connected with a fixed plate 5, and the fixed plate 5 is provided with the punch 4 and the punch 3 Corresponding matching relief holes, so that the lower end of the punch 4 and the punch 3 can pass through the fixing plate 5 . A stripping plate 7 is arranged below the fixed plate 5, and a group of guide rods 7a which form a sliding fit with the upper template 1 are evenly distributed on the stripping plate 7, and each guide rod between the upper template 1 and the stripping plate 7 The 7a shaft is covered with a bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com