A slow-release alkaline molecular sieve deacidification agent and its preparation method and application

A sieve deacidification agent and slow-release technology, which is applied in the field of slow-release alkaline molecular sieve deacidification agent and its preparation, can solve problems such as difficulty in imparting multifunctionality, uncontrollable alkali amount and release, and organic solvent pollution. Achieve good biocompatibility, long-lasting effect, and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

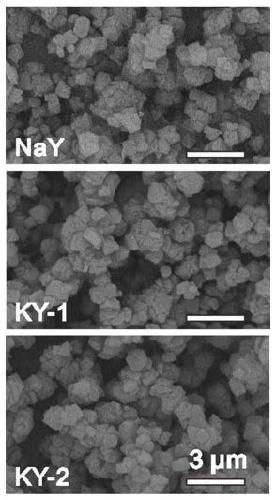

Embodiment 1

[0036] (1) Adopt Y-type molecular sieve, immerse in the potassium nitrate aqueous solution of concentration 5wt%, the mass ratio of this solution and molecular sieve is 10:1, temperature is 60 ℃, reaction time is 2 hours. The solid product was isolated by filtration, washed three times with deionized water, and then dried at 100°C for 12 hours. A basic molecular sieve with a potassium ion exchange degree of 50% is obtained, and a slow-release basic molecular sieve deacidification agent is formulated at a mass ratio of 0.5 wt%.

[0037] (2) The paper was pre-cleaned to remove surface impurities with an ear washing ball, and treated at a constant temperature and humidity for 5 hours at a temperature of 20° C. and a humidity of 10% RH. Deacidification by dipping, the mass ratio of paper to deacidification agent aqueous solution is 0.2:1, soak at room temperature for 20 minutes.

[0038] (3) The deacidified paper is dried at room temperature for 24 hours.

[0039] The paper used...

Embodiment 2

[0041] (1) Adopt Y-type molecular sieve, immerse in the cesium sulfate aqueous solution that concentration is 7wt%, the mass ratio of this solution and molecular sieve is 20:1, temperature is 90 ℃, and reaction time is 8 hours. The solid product was isolated by filtration, washed three times with deionized water, and then dried at 120°C for 20 hours. A basic molecular sieve with a cesium ion exchange degree of 40% is obtained, and a slow-release basic molecular sieve deacidification agent is formulated at a mass ratio of 0.5 wt%.

[0042] (2) The paper is pre-cleaned with an ear washing ball to remove surface impurities, and treated at a constant temperature and humidity for 1 hour at a temperature of 50° C. and a humidity of 50% RH. Deacidification is carried out by immersion, the mass ratio of paper to deacidifier aqueous solution is 0.1:1, the immersion time is 40 minutes, and the temperature is 20°C.

[0043] (3) The deacidified paper is dried at a temperature of 30° C. f...

Embodiment 3

[0046] (1) Adopt Y-type molecular sieve, immerse in the rubidium nitrate aqueous solution whose concentration is 6wt%, the mass ratio of this solution and molecular sieve is 15:1, the temperature is 80 ℃, and the reaction time is 15 hours. The solid product was isolated by filtration, washed three times with deionized water, and then dried at 90°C for 16 hours. A basic molecular sieve with a rubidium ion exchange degree of 45% is obtained, and a slow-release basic molecular sieve deacidification agent is formulated at a mass ratio of 1 wt%.

[0047] (2) The paper is pre-cleaned with an ear washing ball to remove surface impurities, and treated at a constant temperature and humidity for 10 hours at a temperature of 20° C. and a humidity of 30% RH. Deacidification is carried out by immersion, the mass ratio of paper to deacidifier aqueous solution is 0.05:1, the immersion time is 20 minutes, and the temperature is 25°C.

[0048] (3) The deacidified paper is dried at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com