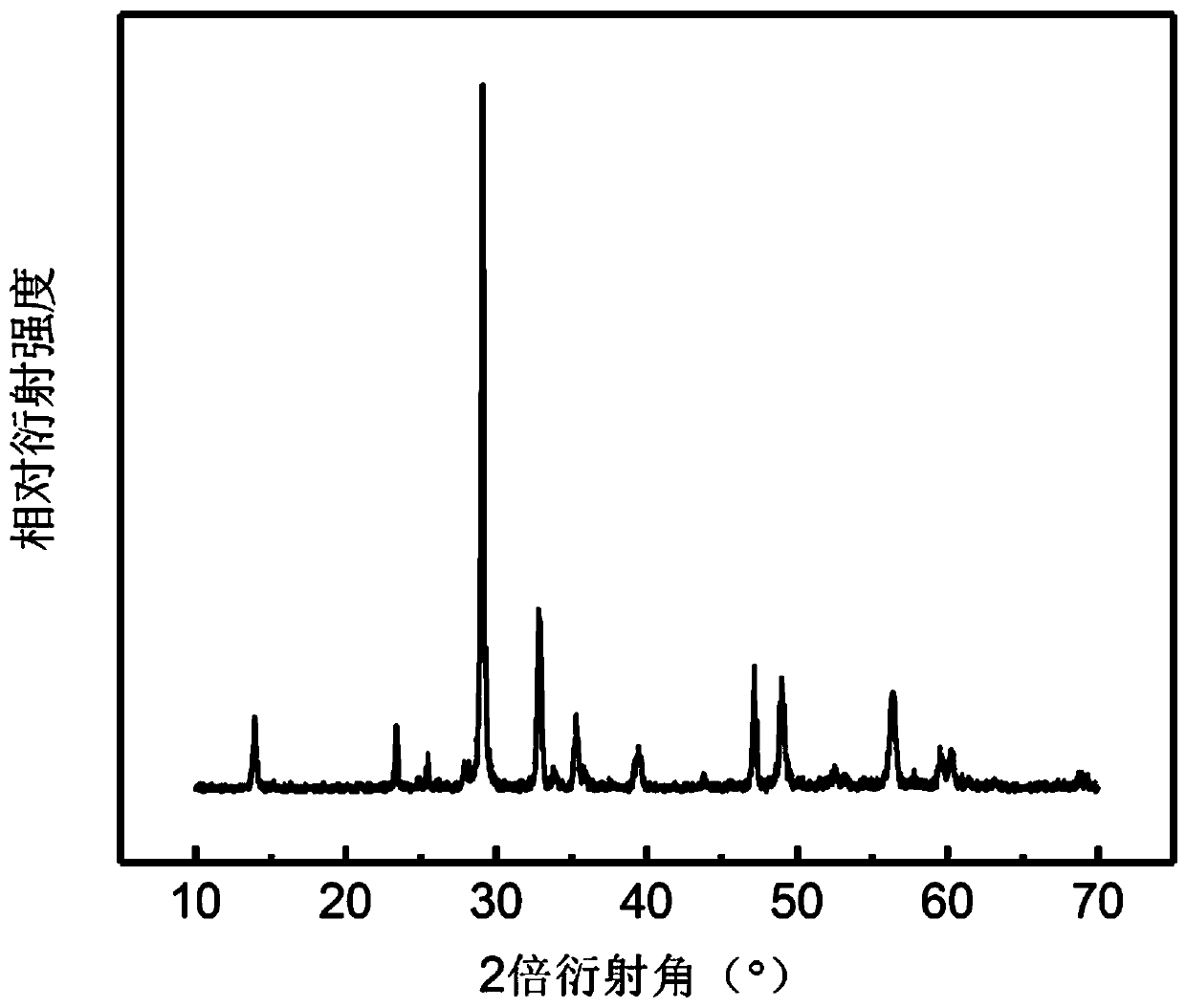

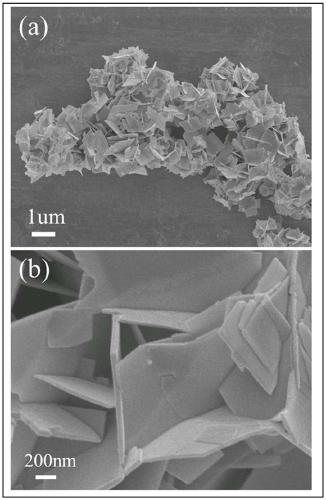

High-photocatalytic-activity single-phase ferroelectric nano-material and preparation method thereof

A nanomaterial, catalytically active technology, applied in the field of catalytic new energy materials, can solve the problems of limited practical application and low absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The application also provides chemical formula as [Bi 2 o 2 ][(Bi 0.9 SM 0.1 )(Fe 0.5 Nb 1.5 )O 7 ] The preparation method of the nanometer material, it may further comprise the steps:

[0032] Add the bismuth source, samarium source, iron source and niobium source into the diluted acid solution according to the stoichiometric ratio, and stir for half an hour to obtain a uniform mixed solution;

[0033] The homogeneous mixed solution was neutralized by adding alkali solution dropwise, and the final alkali concentration of the mixed solution was adjusted to 3mol / L, and the final volume was adjusted to 80mL, and then the obtained yellow suspension was transferred to a polytetrafluoroethylene with a volume of 100mL In the ethylene reactor, put the reactor into an oven at last, and conduct heat treatment under certain conditions to obtain the target powder;

[0034] The obtained target powder is repeatedly centrifuged, washed to neutrality, and then dried to obtain t...

Embodiment 1

[0043] (1) According to the molecular formula stoichiometric ratio weighing 1.8756g purity is 99% bismuth nitrate pentahydrate, 0.0448g purity is 99% samarium nitrate, 0.2693g purity is 98.5% iron nitrate nonahydrate and 0.3198g trihydrate pentoxide Diniobium was added successively to 20 mL of dilute nitric acid with a concentration of 4 mol / L, and the stirring was continued for half an hour to obtain a homogeneous mixture.

[0044] (2) The above-mentioned homogeneous mixed solution was neutralized by dropping sodium hydroxide solution, and the final alkali concentration of the mixed solution was guaranteed to be 3 mol / L by accurately controlling the added sodium hydroxide content (11.36 g), and the final volume was 80 mL. The resulting yellow suspension was then transferred to a polytetrafluoroethylene reactor with a capacity of 100 mL. Finally, put the reactor into an oven, set the heat treatment temperature at 200° C., and the heat treatment time at 72 hours.

[0045] (3) ...

Embodiment 2

[0054] (1) according to molecular formula stoichiometric ratio weighing 1.8756g purity is 99% bismuth nitrate pentahydrate, 0.0448g purity is 99% samarium nitrate, 0.2693g purity is 98.5% ferric nitrate nonahydrate and 0.5403g niobium pentachloride Then add 20 mL of dilute nitric acid with a concentration of 4 mol / L in sequence, and continue stirring for half an hour to obtain a uniform mixed solution.

[0055] (2) The above-mentioned homogeneous mixed solution was neutralized by dropping sodium hydroxide solution, and the final alkali concentration of the mixed solution was guaranteed to be 3 mol / L by accurately controlling the added sodium hydroxide content (11.36 g), and the final volume was 80 mL. The resulting yellow suspension was then transferred to a polytetrafluoroethylene reactor with a volume of 100 mL. Finally, put the reactor into an oven, set the heat treatment temperature at 200° C., and the heat treatment time at 72 hours.

[0056] (3) The powder obtained by hyd...

PUM

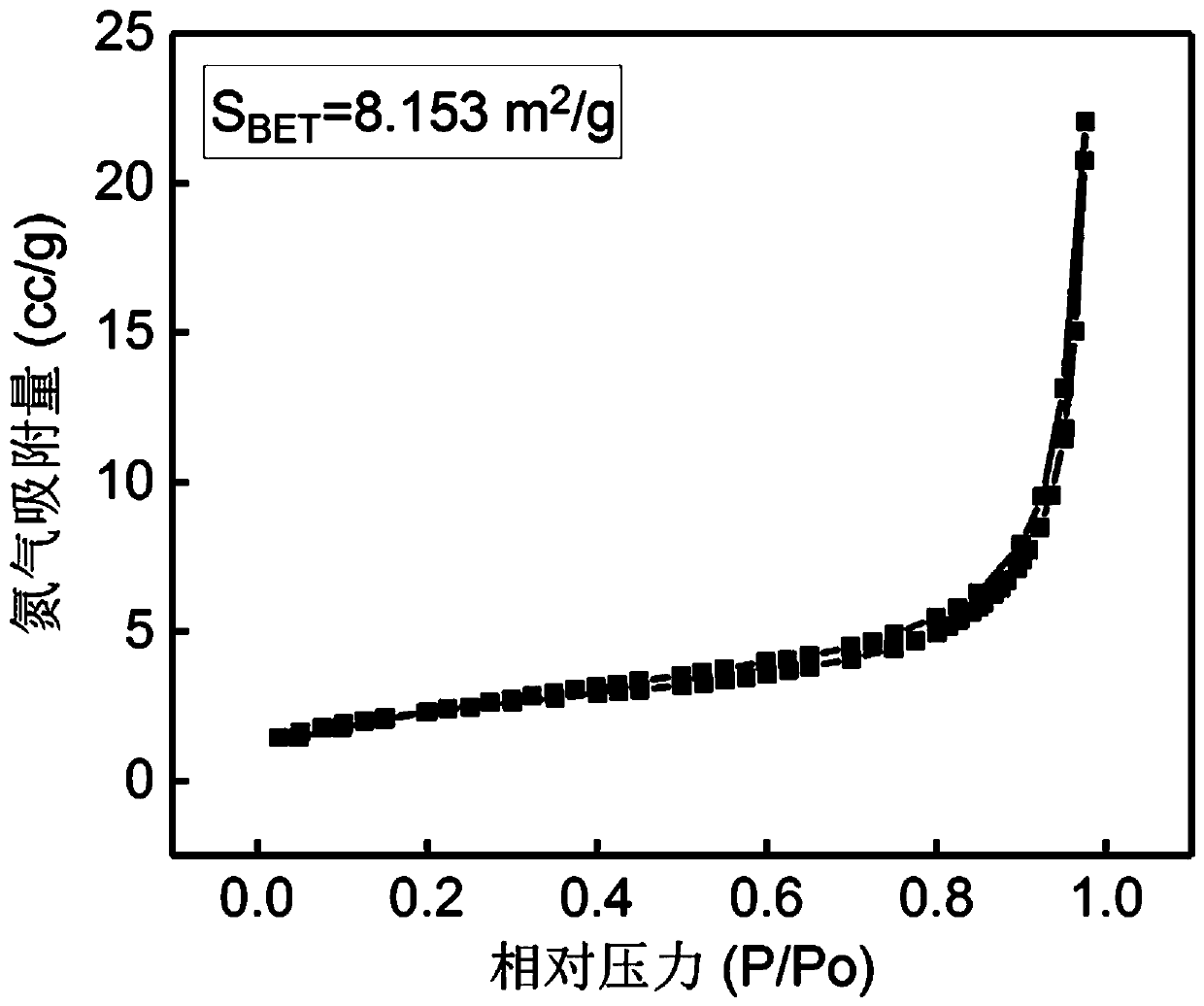

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com