Preparation method of deacidification functional paper with pH-responsive fluorescent probe

A fluorescent probe and deacidification technology, which is applied in the direction of fluorescence/phosphorescence, material analysis through optical means, and measurement devices, can solve the problems of limited test accuracy and the inability to judge the effect of acidification degree of paper non-destructively, and achieve compatibility Good anti-aging, anti-aging degree, and the effect of inhibiting the acidification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

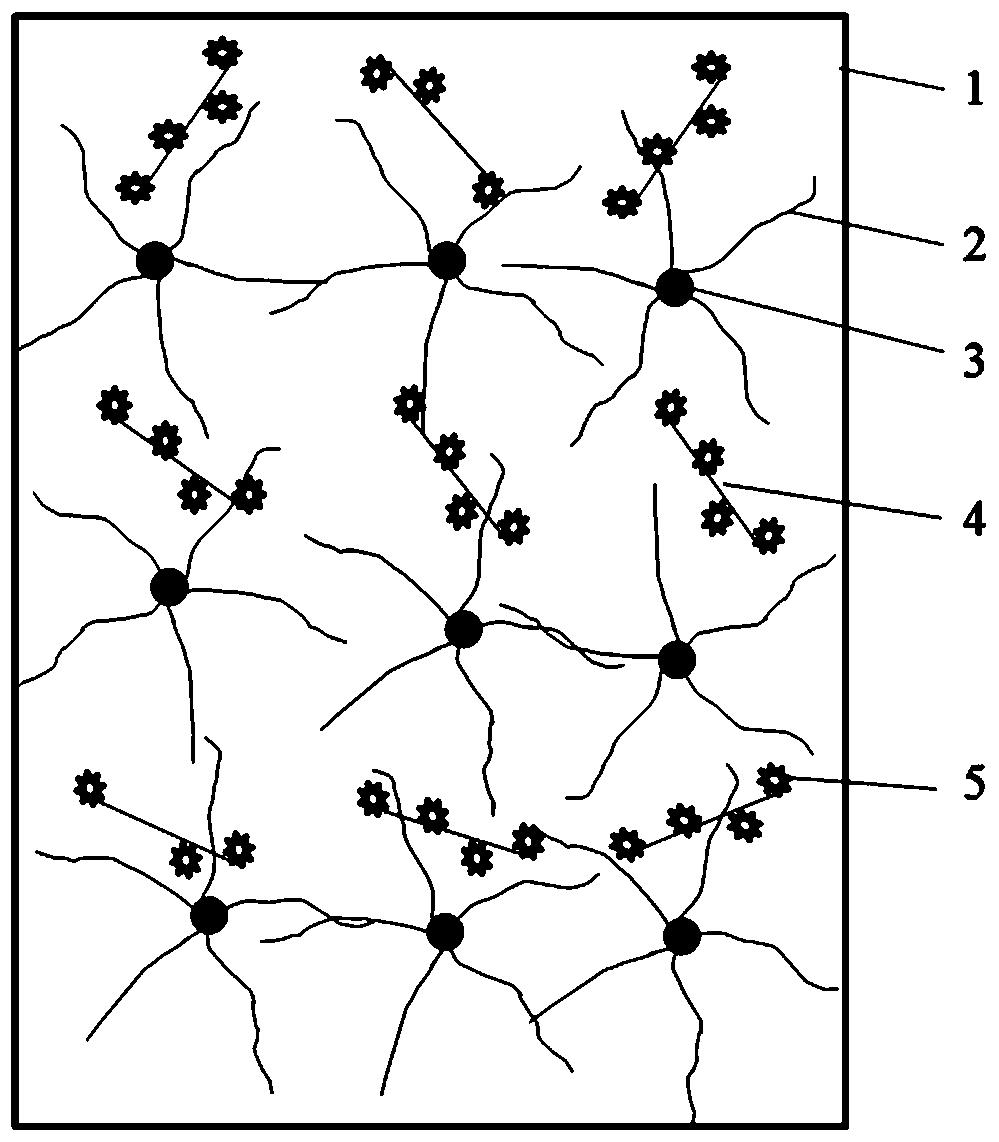

[0027](1) The starch solution with a mass fraction of 3%, the mixture of nano-zinc oxide, nano-magnesium oxide, and nano-titanium dioxide with a mass fraction of 1% (mass ratio of 1:2:1) and water with a mass fraction of 96% were mixed at 40 Stirring for 12 hours at a speed of 50 revolutions per minute at a temperature of 0° C. to obtain a nano-alkaline composite deacidification agent solution of starch-grafted nano-zinc oxide, nano-magnesium oxide and nano-titanium dioxide.

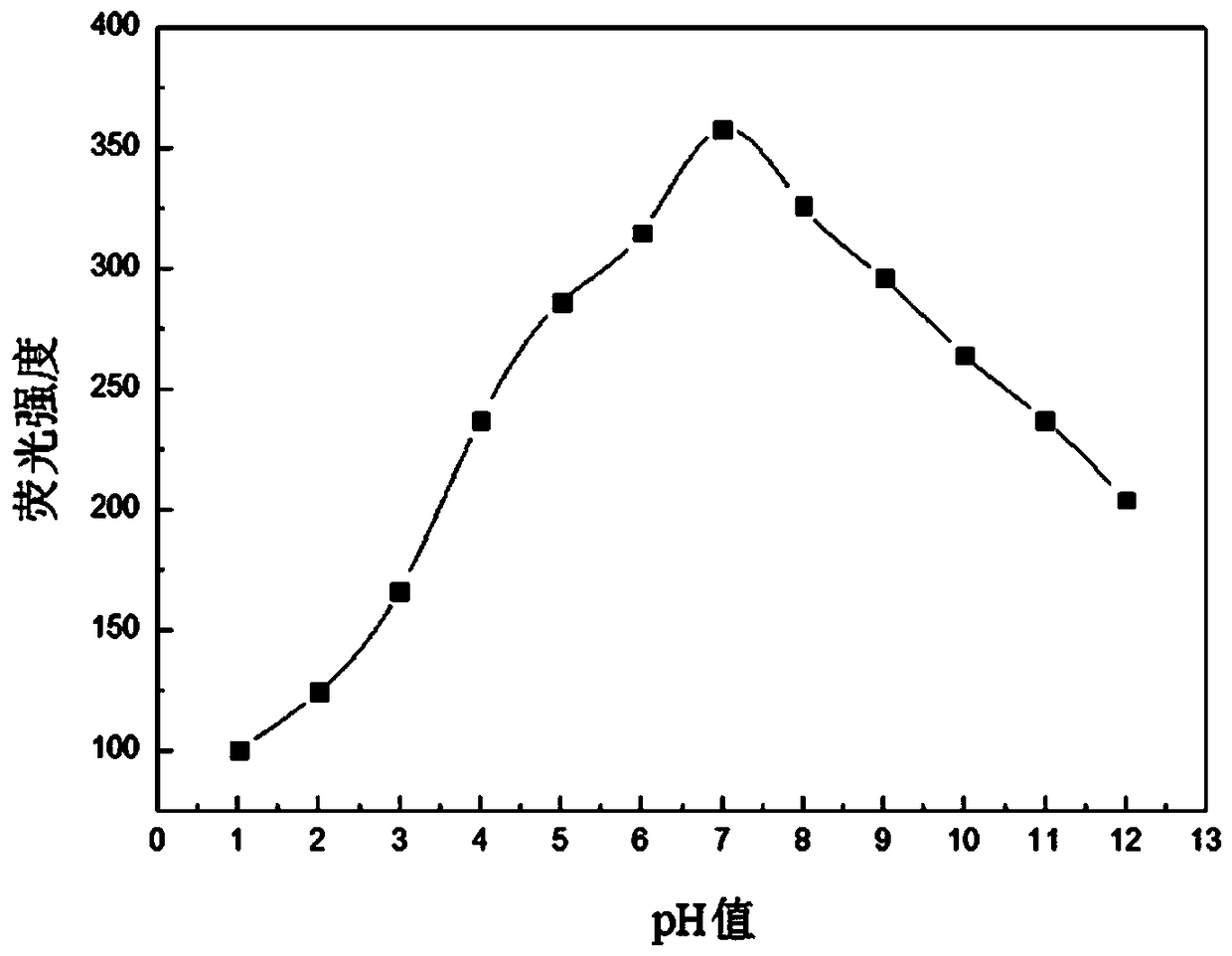

[0028] (2) For the rhodamine isothiocyanate-grafted cellulose-based material, 1 g of microcrystalline cellulose was added to 5 ml of epichlorohydrin, and stirred at 40° C. for 5 hours. The reaction mixture was dialyzed with deionized water for 75 hours, 1 g of ammonium chloride was added to the suspension, stirred at 40° C. for 6 hours, and dialyzed with deionized water for 65 hours; 5 ml of dimethylformamide and 0.03 g of rhodamine isothiocyanate was stirred for 12 hours without light to obtain a cellul...

Embodiment 2

[0032] (1) The starch solution with a mass fraction of 5%, the mixture of nano-zinc oxide, nano-magnesium oxide, and nano-titanium dioxide with a mass fraction of 5% (mass ratio of 1:3:2) and 90% of water at 60 Stirring for 36 hours at a speed of 200 revolutions per minute at a temperature of °C to obtain a nano-alkaline composite deacidification agent solution of starch-grafted nano-zinc oxide, nano-magnesium oxide and nano-titanium dioxide.

[0033] (2) Add 1 g of microcrystalline cellulose to 8 ml of epichlorohydrin, and stir at 60° C. for 8 hours. The reaction mixture was dialyzed against deionized water for 70 hours, 3 g of ammonium chloride was added to the suspension, stirred at 60° C. for 18 hours, and dialyzed against deionized water for 75 hours. 20 ml of dimethylformamide and 0.08 g of rhodamine isothiocyanate were added to the suspension, and stirred for 36 hours without light to obtain a pH-responsive cellulose-based fluorescent probe.

[0034] (3) The nano-alkal...

Embodiment 3

[0037] (1) The starch solution with a mass fraction of 4%, the mixture of nano-zinc oxide, nano-magnesia, and nano-titanium dioxide with a mass fraction of 3% (mass ratio of 1:2:1) and water with a mass fraction of 93% were mixed at 50 Stirring at a speed of 100 rpm for 24 hours at a temperature of 100° C. to obtain a nano-alkaline composite deacidification agent solution of starch-grafted nano-zinc oxide, nano-magnesium oxide and nano-titanium dioxide.

[0038] (2) Add 1 g of microcrystalline cellulose to 10 ml of epichlorohydrin, and stir at 50° C. for 6 hours. The reaction mixture was dialyzed against deionized water for 80 hours, 2 g of ammonium chloride was added to the suspension, stirred at 50° C. for 12 hours, and dialyzed against deionized water for 80 hours. 10 ml of dimethylformamide and 0.06 g of rhodamine isothiocyanate were added to the suspension, and stirred for 24 hours without light to obtain a pH-responsive cellulose-based fluorescent probe.

[0039] (3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com