Welded ball mesh frame locating device for building house with long span

A positioning device, welding ball technology, applied in the processing of building materials, construction, building structure and other directions, can solve the problems of difficult construction, low precision, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

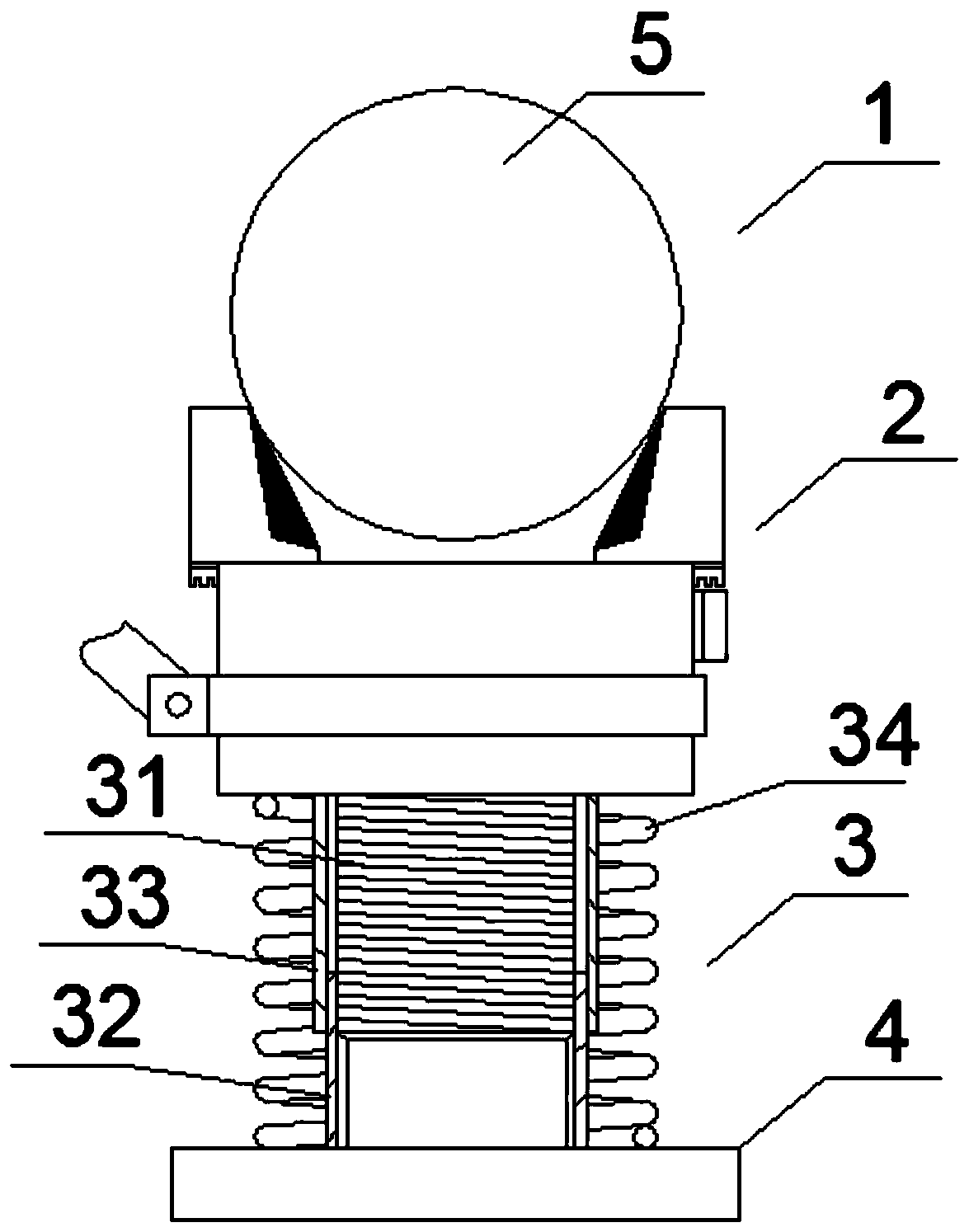

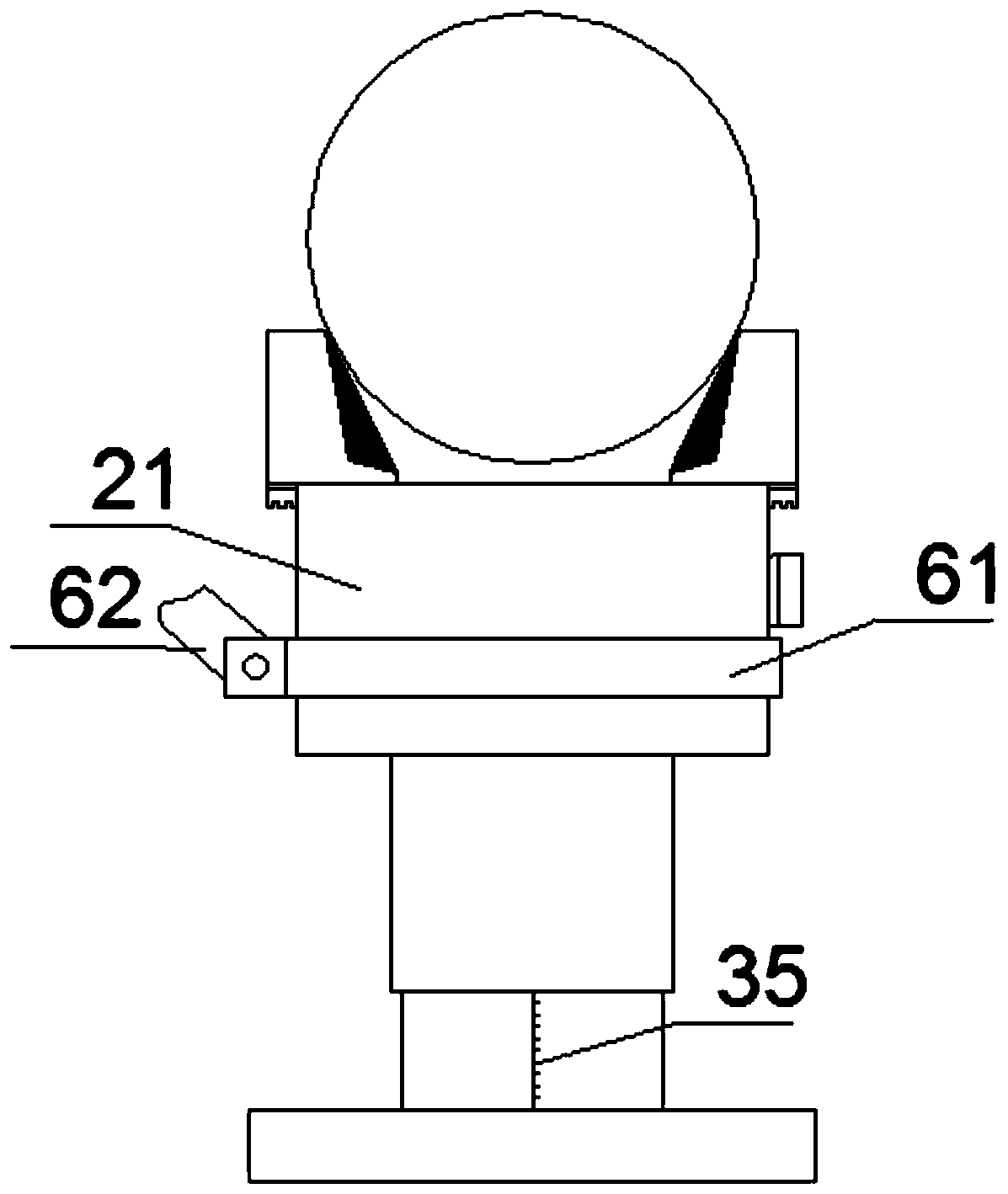

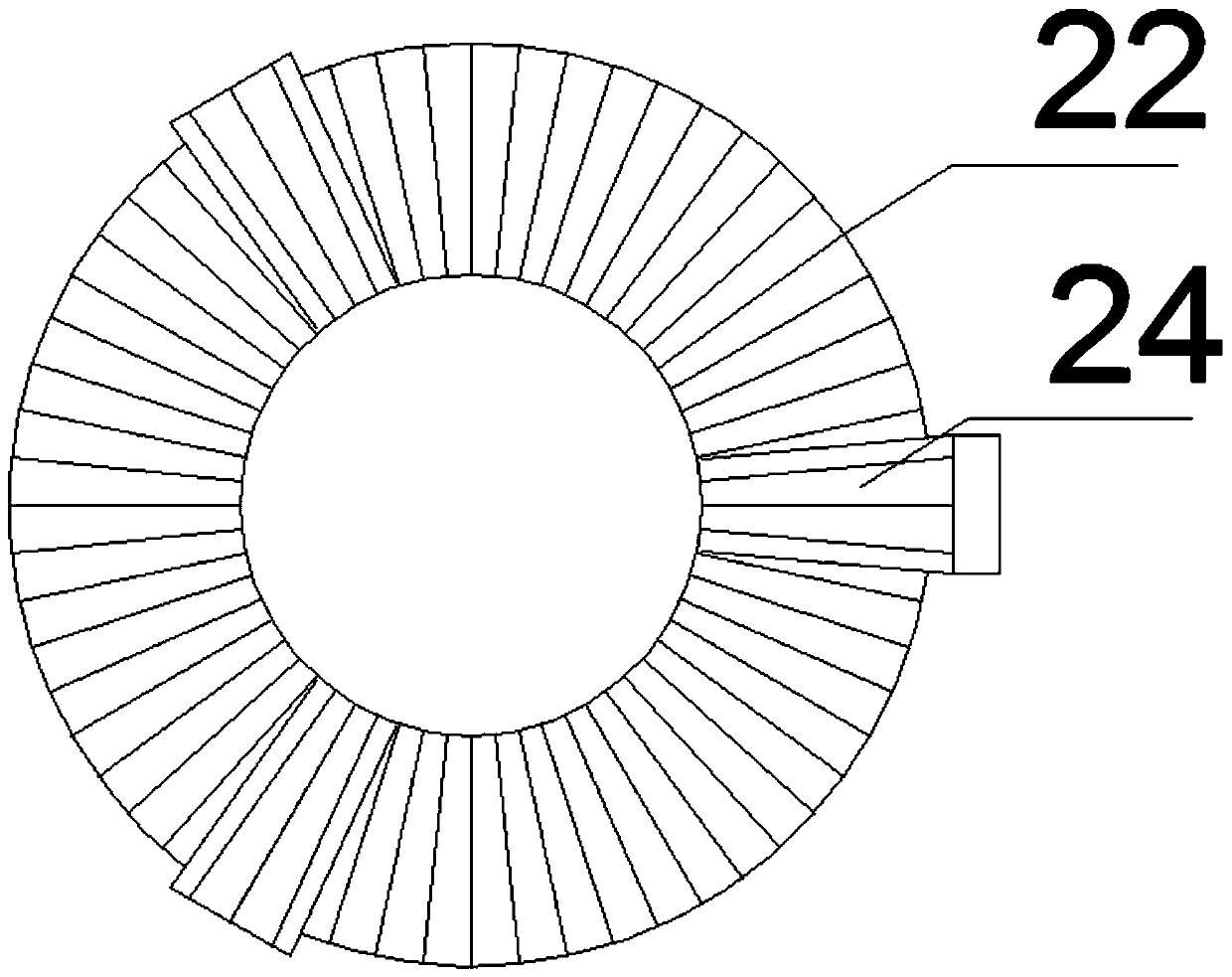

[0025] See attached Figure 1~8 . A welding ball grid positioning device for the roof of a large-span building includes a number of ball holding units 1 and a number of connecting mechanisms 6; the ball holding unit 1 includes a ball holding adjustment mechanism 2, a height adjustment mechanism 3, and a support seat 4; The supporting ball adjusting mechanism 2 includes a cylindrical shell 21, a large bevel gear disk 22, six supporting claws 23 and three small bevel teeth 24; the cylindrical shell 21 is provided with three rotating shafts on the circumferential surface thereof. Small bevel teeth 24; the three small bevel teeth 24 mesh with the bottom of the large bevel gear disk 22 for driving the large bevel gear disk 22 to rotate in the cylindrical housing 21; the top of the large bevel gear disk 22 is provided with a plane thread The bottom of the pawl 23 is provided with bottom teeth, the bottom teeth are matched with the plane thread; when the large bevel gear disk 22 rota...

Embodiment 2

[0027] See attached Figure 1~8 . A welding ball grid positioning device for the roof of a large-span building includes a number of ball holding units 1 and a number of connecting mechanisms 6; the ball holding unit 1 includes a ball holding adjustment mechanism 2, a height adjustment mechanism 3, and a support seat 4; The supporting ball adjusting mechanism 2 includes a cylindrical shell 21, a large bevel gear disk 22, six supporting claws 23 and three small bevel teeth 24; the cylindrical shell 21 is provided with three rotating shafts on the circumferential surface thereof. Small bevel teeth 24; the three small bevel teeth 24 mesh with the bottom of the large bevel gear disk 22 for driving the large bevel gear disk 22 to rotate in the cylindrical housing 21; the top of the large bevel gear disk 22 is provided with a plane thread The bottom of the pawl 23 is provided with bottom teeth, the bottom teeth are matched with the plane thread; when the large bevel gear disk 22 rota...

Embodiment 3

[0030] See attached Figure 1~8 . A welding ball grid positioning device for the roof of a large-span building includes a number of ball holding units 1 and a number of connecting mechanisms 6; the ball holding unit 1 includes a ball holding adjustment mechanism 2, a height adjustment mechanism 3, and a support seat 4; The supporting ball adjusting mechanism 2 includes a cylindrical shell 21, a large bevel gear disk 22, six supporting claws 23 and three small bevel teeth 24; the cylindrical shell 21 is provided with three rotating shafts on the circumferential surface thereof. Small bevel teeth 24; the three small bevel teeth 24 mesh with the bottom of the large bevel gear disk 22 for driving the large bevel gear disk 22 to rotate in the cylindrical housing 21; the top of the large bevel gear disk 22 is provided with a plane thread The bottom of the pawl 23 is provided with bottom teeth, the bottom teeth are matched with the plane thread; when the large bevel gear disk 22 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com