Cable welding device and cable welding method for pcb board

A cable welding and cable technology, applied in circuits, connections, electrical components, etc., can solve the problems of low cable welding efficiency, and achieve the effects of simple structure, convenient disassembly and assembly, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

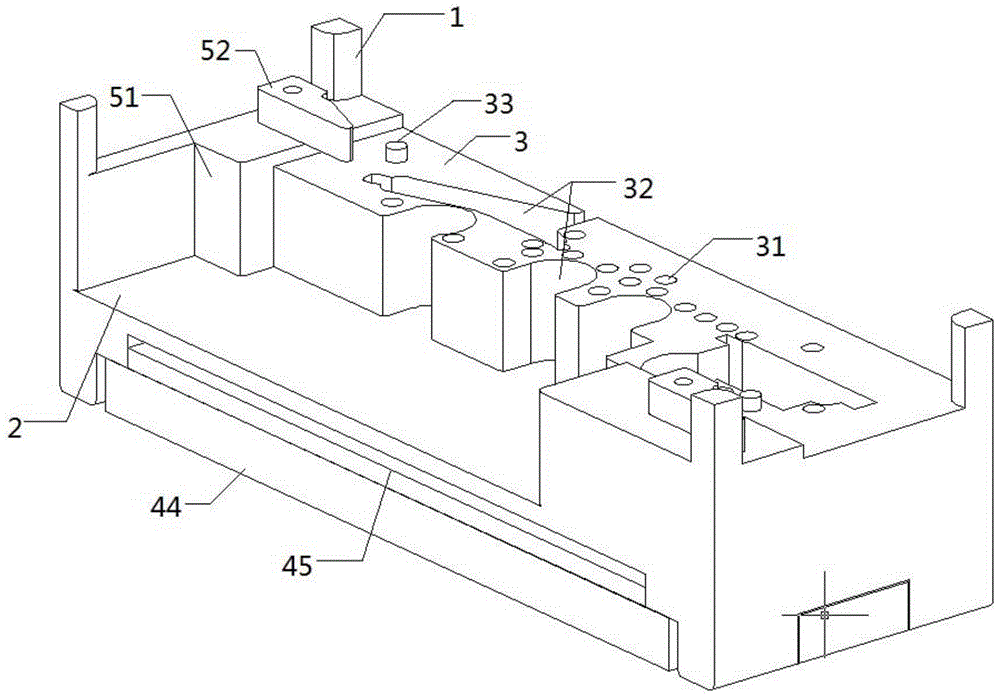

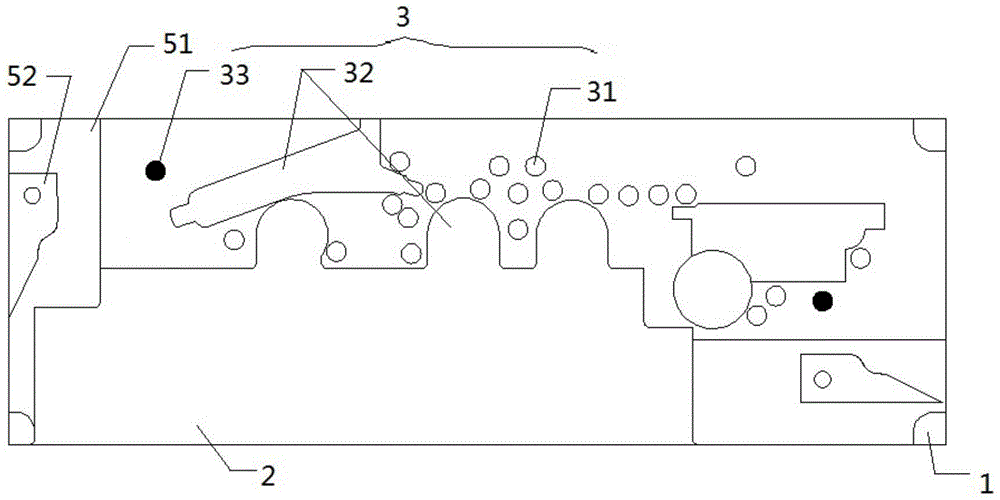

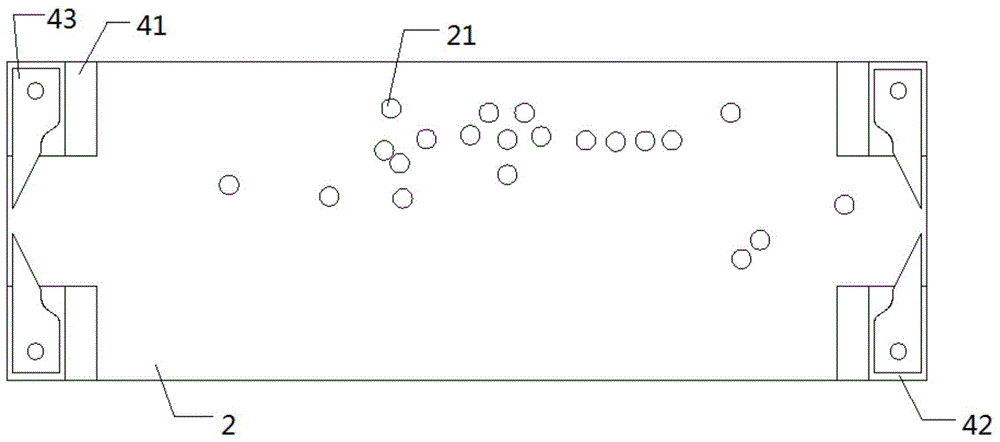

[0026] according to Figure 1 to Figure 5 Shown: a cable welding device, including: a support leg 1, a substrate 2 with a substrate hole 21 at the bottom, a welding table 3 with a cable hole 31 at the top, a cable locking device 4, and a PCB submodule locking assembly 5 , the supporting legs 1 are arranged on the four ends of the upper part of the substrate 2, and are used to support the substrate 2, and the lower part of the welding table 3 for carrying the PCB sub-module for welding work is stacked with the substrate 2 in sequence 1. The cable locking device 4 for clamping and fixing the cable, the PCB submodule locking assembly 5 for pressing and fixing the PCB submodule is provided at both longitudinal ends of the welding workbench 3, and the The PCB sub-module locking assembly 5 is arranged on the substrate 2 and shares the bottom surface with the welding table 3; the cable hole 31 and the substrate hole 21 communicate with each other to form a channel, so that the cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com