A processing method for a flat fork tooling combination of a vehicle frame

A processing method and flat fork technology, which can be used in metal processing equipment, manufacturing tools, auxiliary devices, etc., and can solve problems such as no welding positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

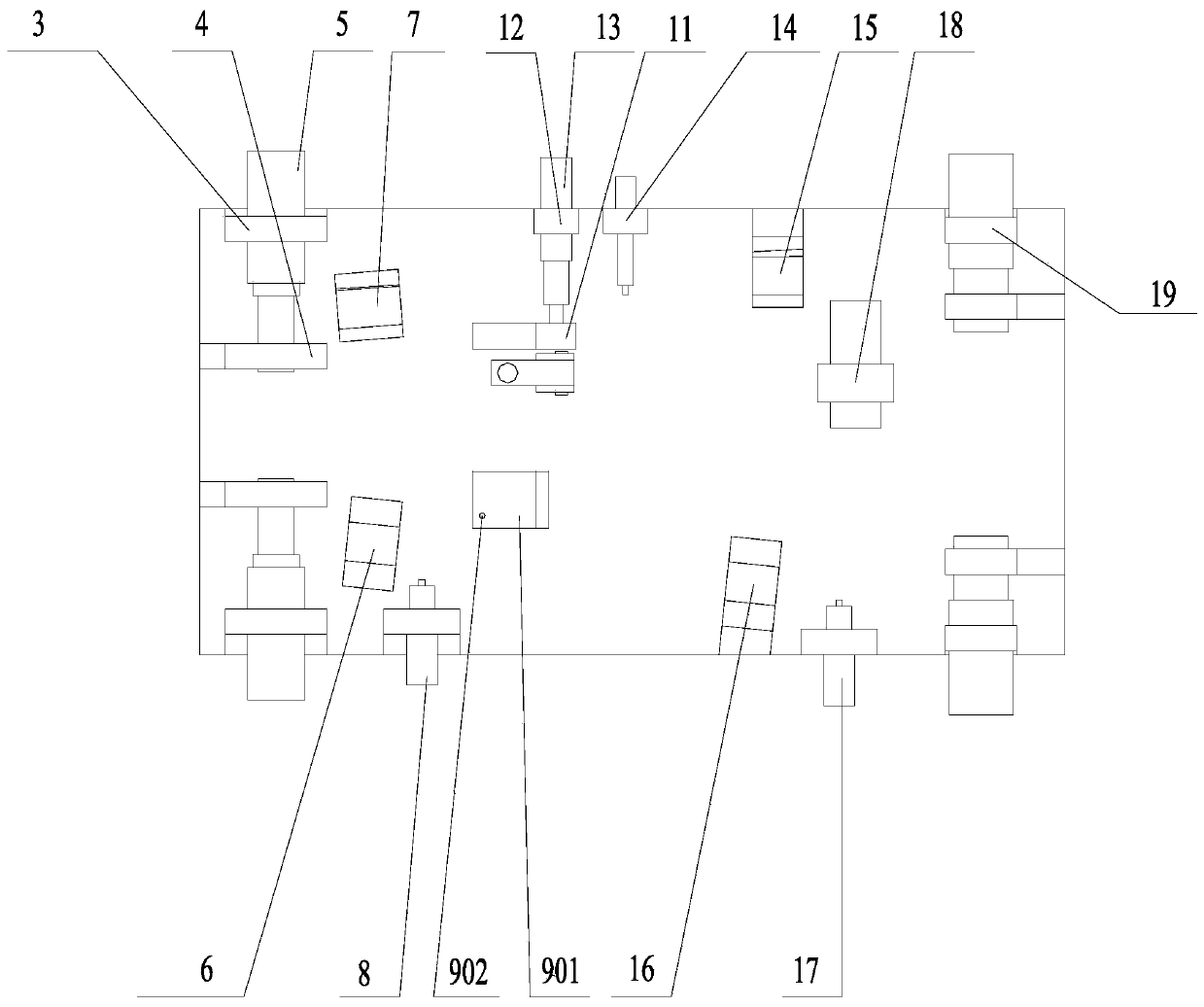

[0032] The invention provides a processing method for the frame flat fork tooling combination, which can perform overall positioning welding for the frame flat fork tooling under the above structure, is reliable in fixing, can improve welding efficiency and welding quality, and reduces labor intensity of workers.

[0033] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

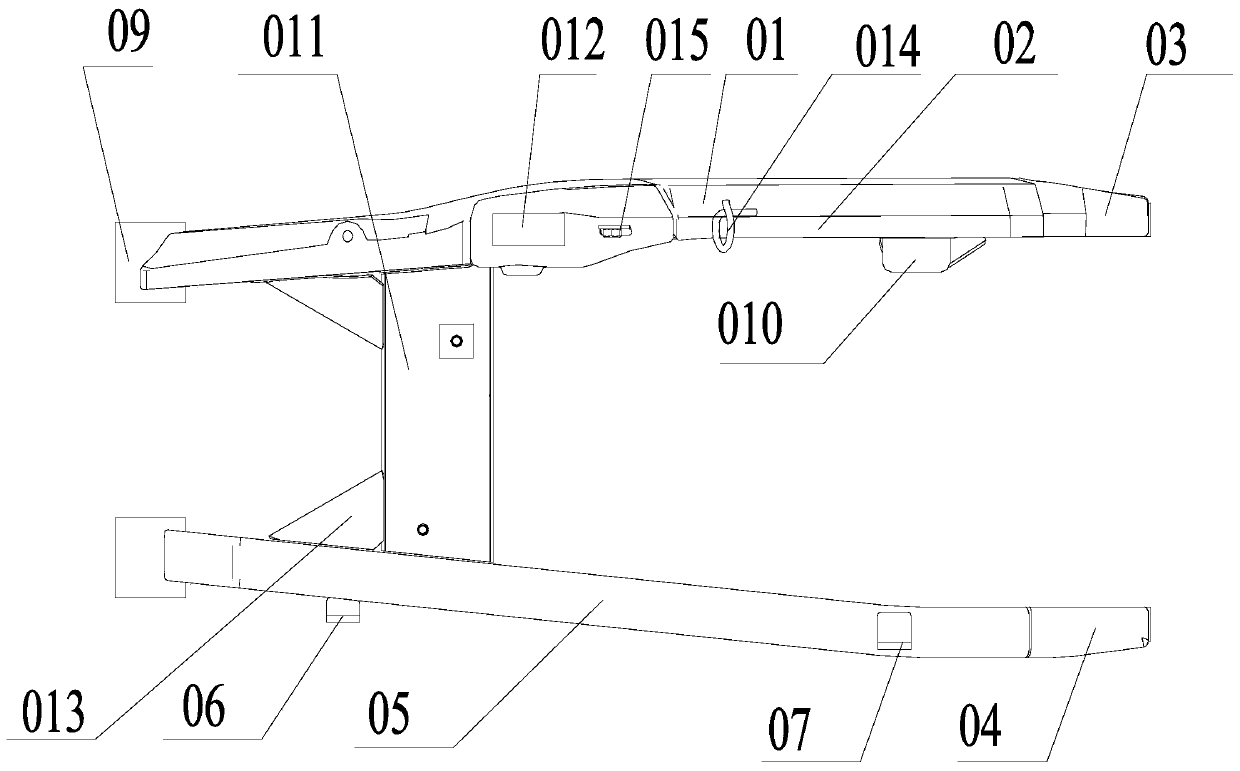

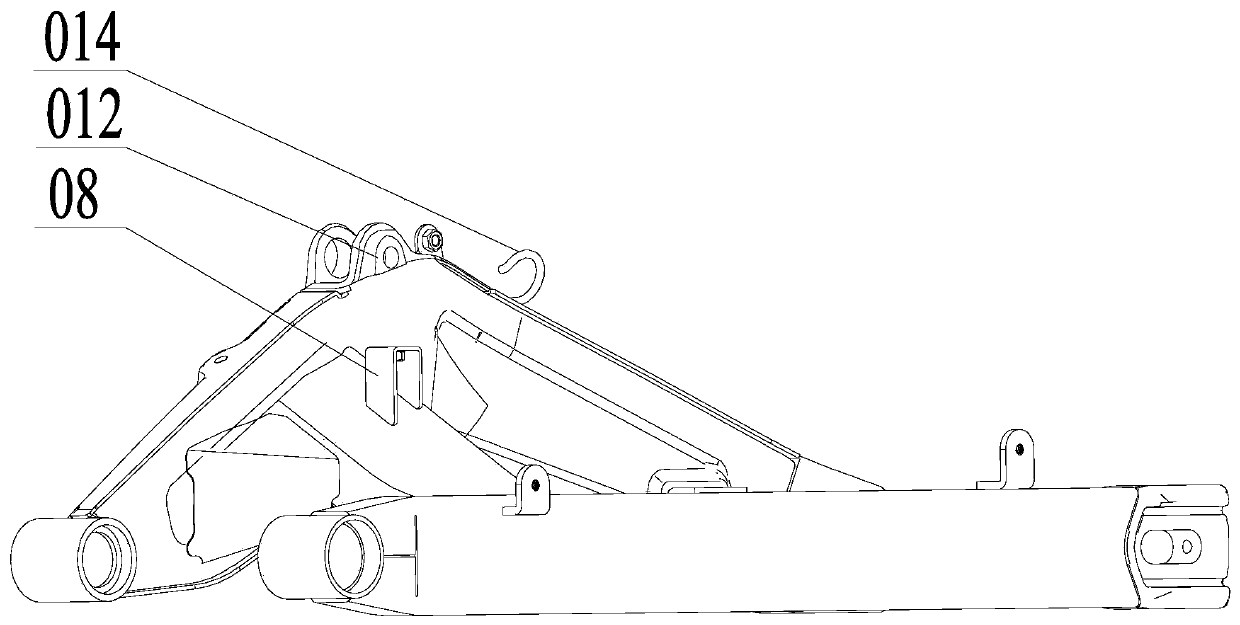

[0034] Please refer to Figure 1-Figure 6 , the processing method of a kind of vehicle frame flat fork tooling combination provided by the present invention, comprises the following steps:

[0035] 1) Position the left pipe 05 of the flat fork, the right pipe of the flat fork, the rear shock absorber 012, the right chain adjuster block 03, the left chain adjuster block 04 and the front connecting pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com