Tool and method for rapid assembly of driving motherboard and electric connectors

A technology for electrical connectors and motherboards, applied in the field of rapid assembly of drive motherboards and electrical connectors, can solve problems such as low production efficiency, achieve high production efficiency, avoid component surfaces and welding surfaces, and be easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

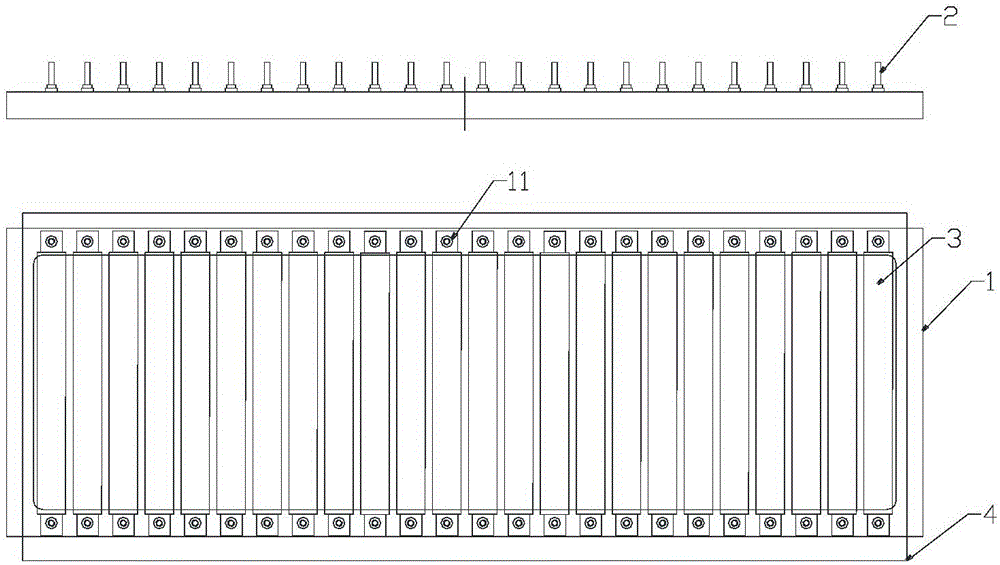

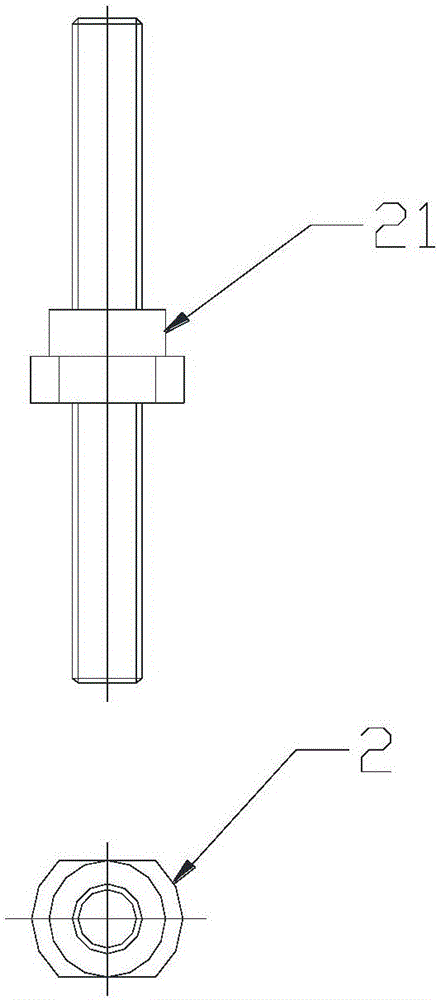

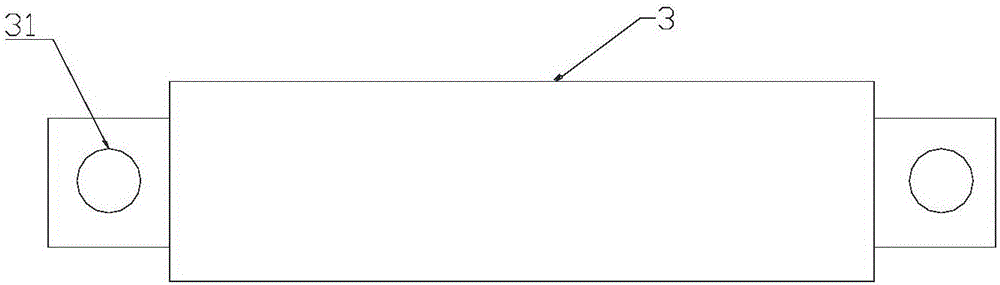

[0033] Such as figure 1 As shown, a tooling for quick assembly of a drive motherboard and an electrical connector in this embodiment includes a support part 1 and a plurality of mutually parallel studs 2 arranged on the support part 1, one end of the stud 2 is connected to the The support part 1 is screwed, and by rotating the stud 2, one end of the plurality of studs 2 is located in the same plane, and the two ends of the plurality of electrical connectors 3 are connected to any two ends of the support part 1. The ends of the studs 2 are fixedly connected, and the drive motherboard 4 is fit and crimped and fixed on the side surface of the electrical connector 3 away from the supporting part 1 .

[0034] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com