Non-linear Lamb wave mixing method for measuring stress distribution in metal sheet

A stress distribution, nonlinear technology, applied in the direction of measuring force, measuring device, using sonic/ultrasonic/infrasonic waves to analyze solids, etc., to achieve the effect of suppressing the influence of system nonlinearity and flexible selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Combine below Figure 1 to Figure 8 The implementation process of the stress distribution detection method based on nonlinear reverse collinear frequency mixing of two columns of A0 waves is described in detail.

[0054] 1) According to Figure 4 Connect the experimental instruments and arrange the experimental probes. The test piece selected in this experiment is 45Mn steel material, and its size is a thin plate with a length of 30mm, a width of 20mm, and a thickness of 2.5mm. In the middle of the length direction of the specimen, there is a milling area with a length of 20 mm and a width of 7.5 mm.

[0055] 2) Excitation signal f 1 , f 2 The excitation position is set at the left and right ends of the model respectively, and the receiving position is set at a position 150 mm away from the left end face in the length direction.

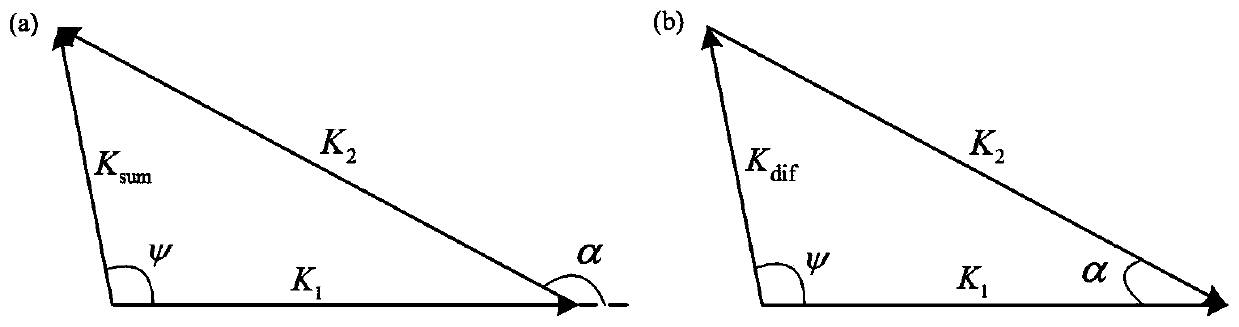

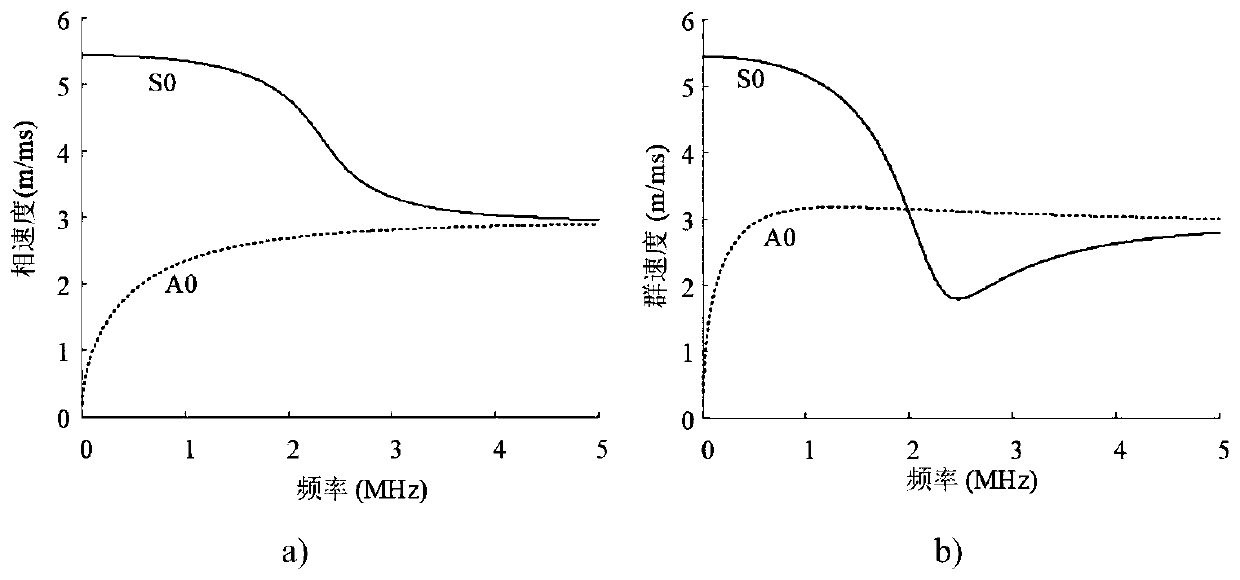

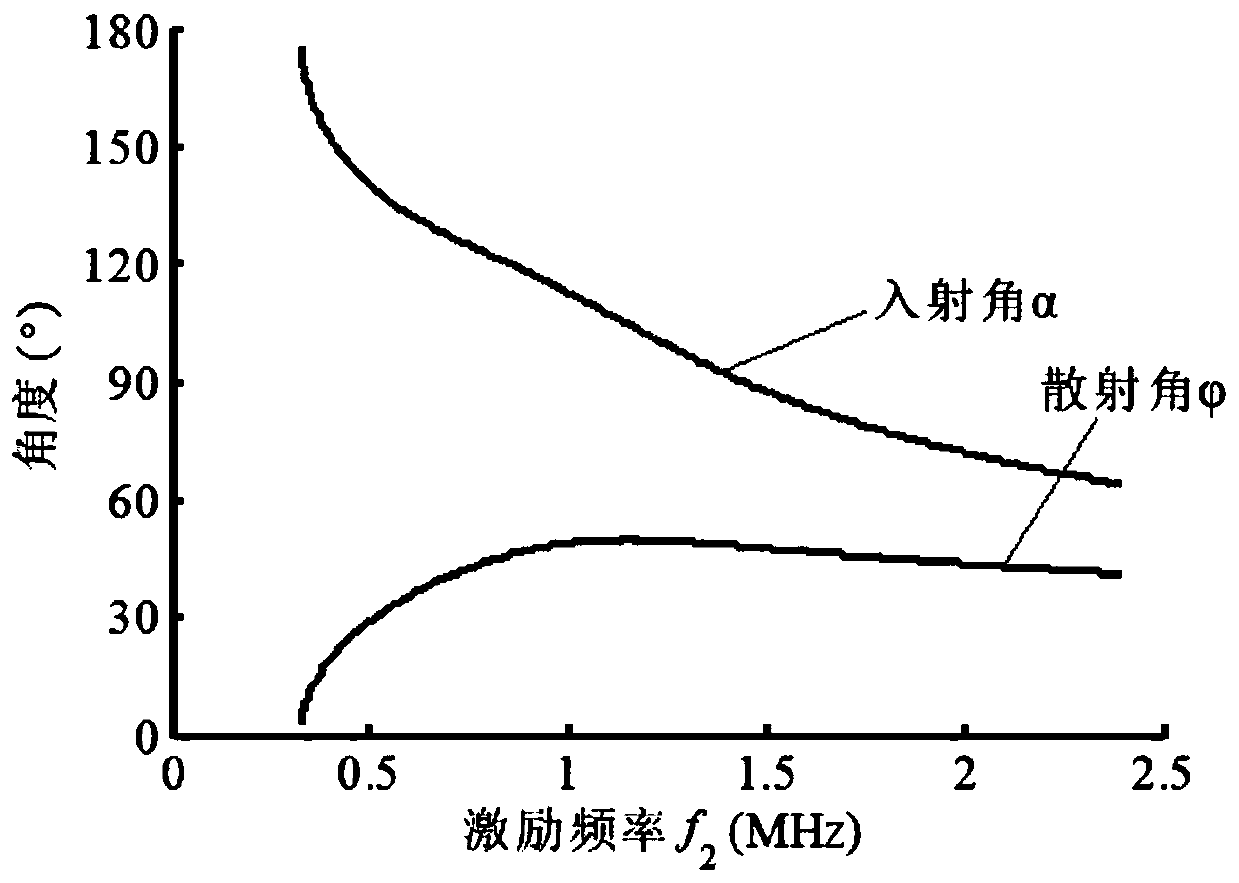

[0056] 3) According to image 3 Two-column A0 wave mixing resonance condition, determining the frequency f of the two excitation signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com