Force balancing resonance micro-mechanical gyro

A technology of micro-mechanical gyroscope and force balance, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, measuring device, etc., and can solve the problems of insufficient sensitivity and resolution of micro-mechanical gyroscope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

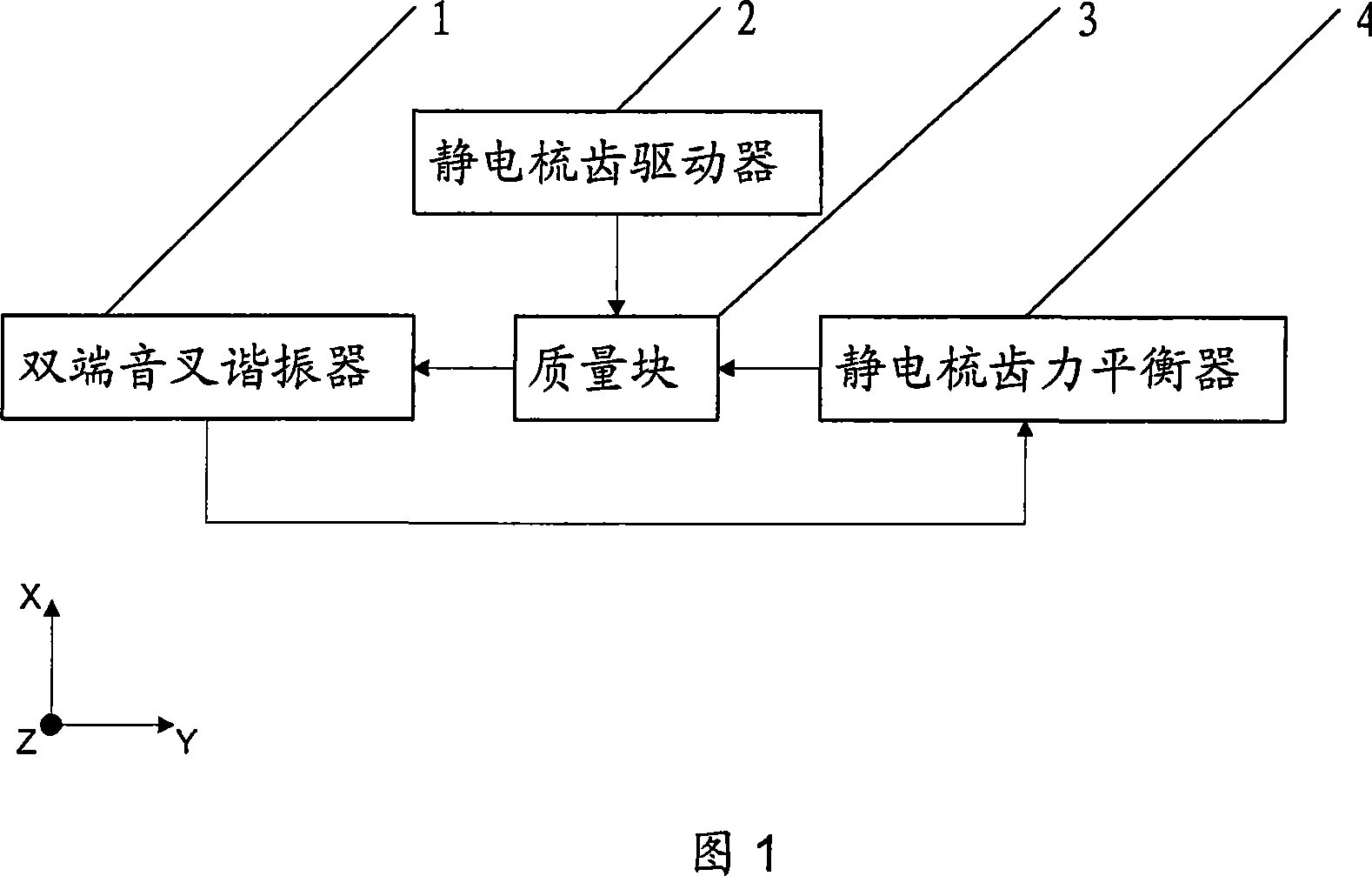

[0020] As shown in Fig. 1, the present invention consists of four parts: a double-ended tuning fork resonator 1, an electrostatic comb driver 2, a mass block 3, and an electrostatic comb force balancer 4, and the entire structure is an axisymmetric figure. The mass block 3 is in the middle position and has two degrees of freedom in x and y directions. Two electrostatic comb drives 2 fixed on the base are symmetrically placed in the x direction, and two electrostatic comb drives 2 fixed on the base are symmetrically placed in the y direction. Electrostatic comb force balancer 4 and two double-ended tuning fork resonators DETF 1.

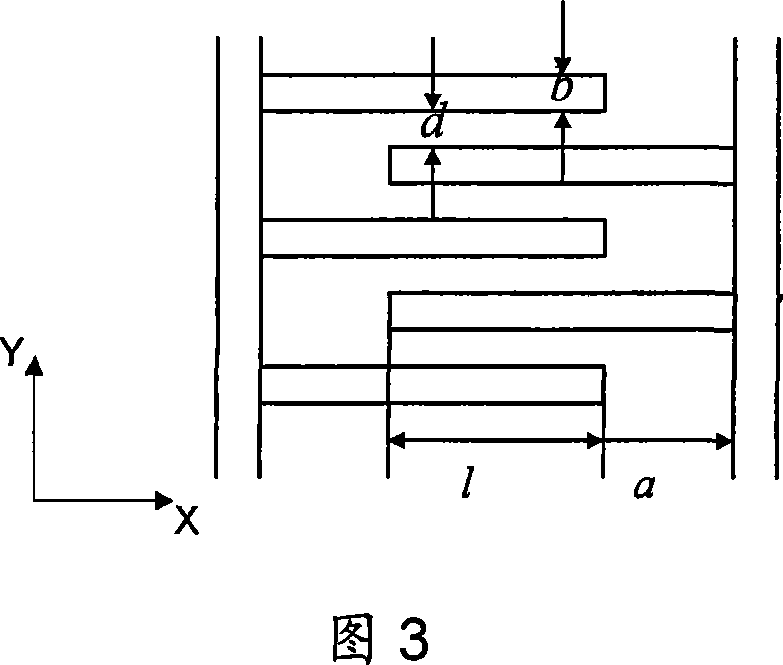

[0021] As shown in Figure 4, the double-ended tuning fork resonator 1 includes a driving static tooth 6, a measuring static tooth 7, a beam 11 and a movable tooth 5, wherein two symmetrical tuning fork beams perform simple harmonic vibration, and the driving static teeth 6 and The movable tooth 5 constitutes a pair of dynamic and static comb teeth, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com