Vibration damper with viscous damper structure for structural testing machine

A technology for viscous dampers and structural testing, which is used in the testing of machine/structural components, shock absorbers, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

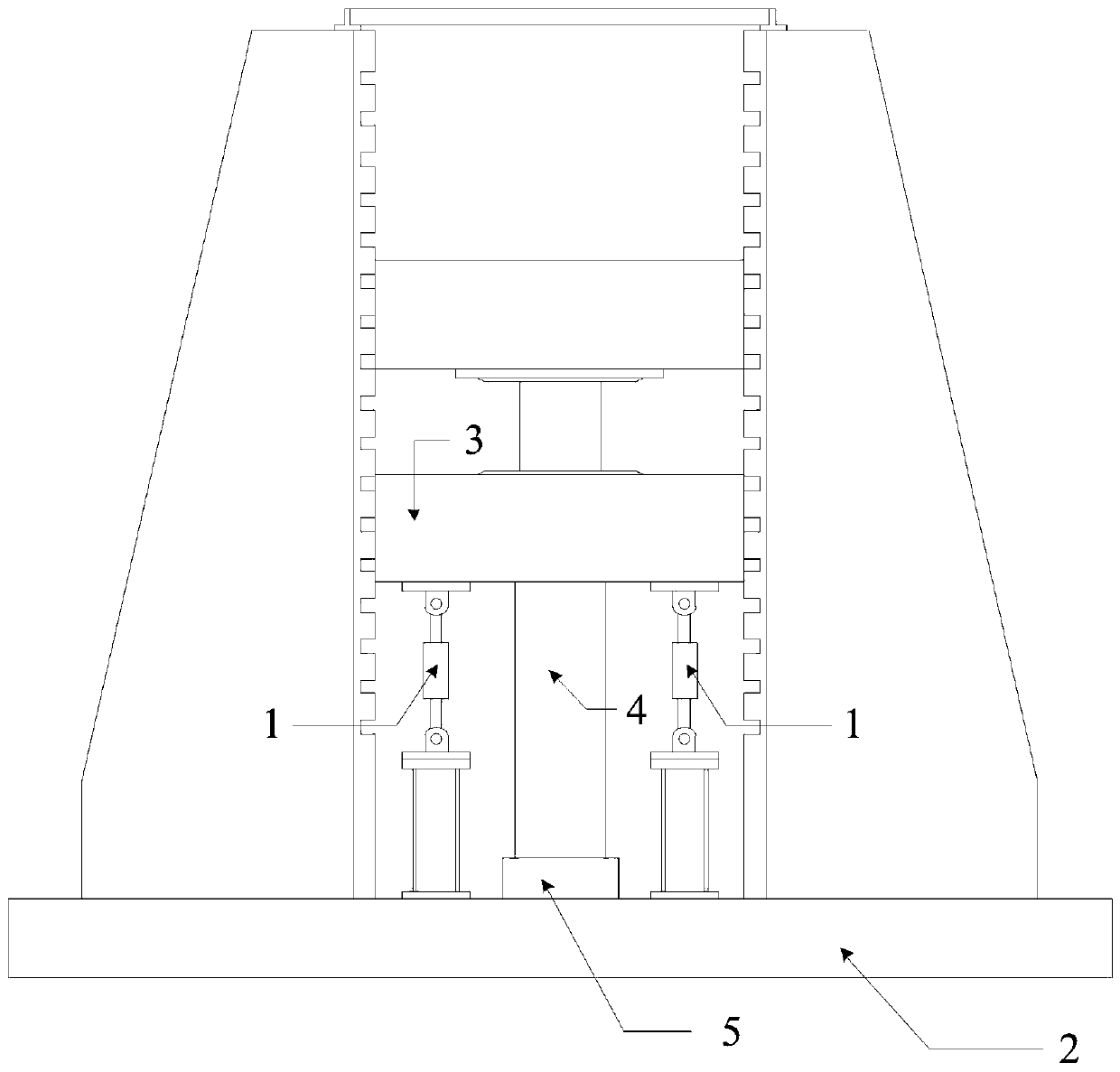

[0016] figure 1 The test system includes a viscous damper device 1, a foundation 2, a lower beam 3 of the testing machine, a test piece 4 and a force sensor; it is characterized in that: the viscous damper device 1 and the test piece 4 are placed under the foundation 2 and the testing machine Between the beams 3, the force sensor 5 is placed at the lower end of the test piece 4 to form a test system; the loading cylinder drives the lower beam 3 of the testing machine to apply a load to the test piece 4, and the viscous damper device 1 and the test piece 4 are jointly stressed. After the test piece 4 is broken, the viscous damper device 1 can bear the load applied by the testing machine, so that the potential energy stored in the testing machine is gradually unloaded to achieve the vibration reduction effect.

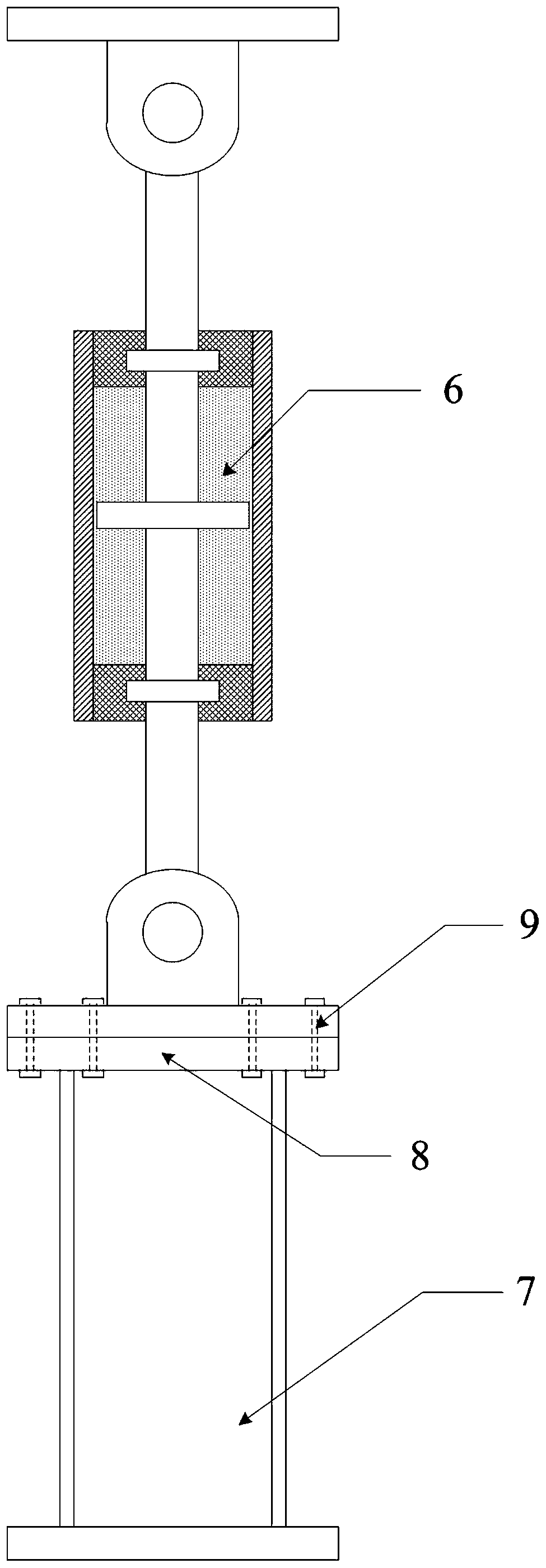

[0017] The viscous damper device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com