power line rack

A technology of power lines and carriages, applied in the direction of electrical components, etc., can solve problems such as inability to erect and limited number of erected power cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

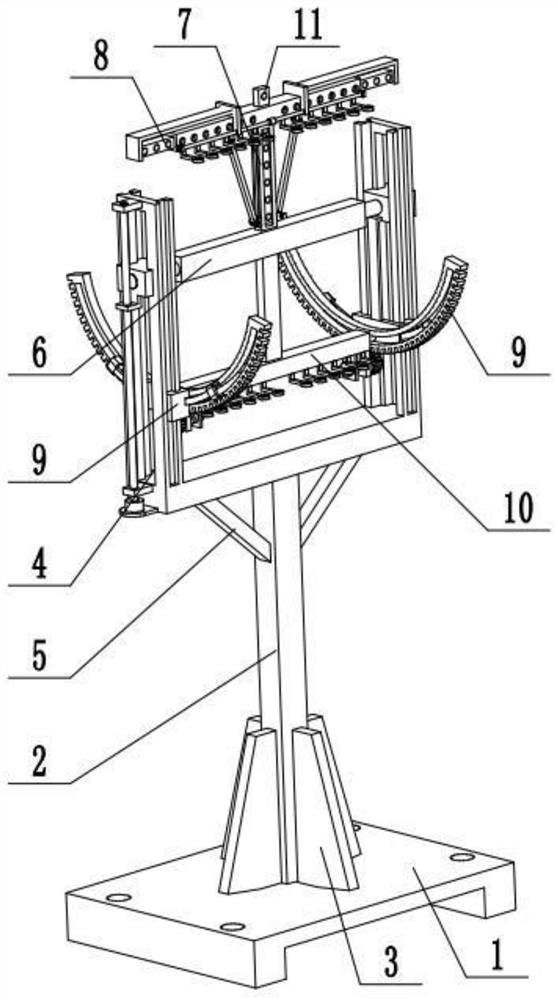

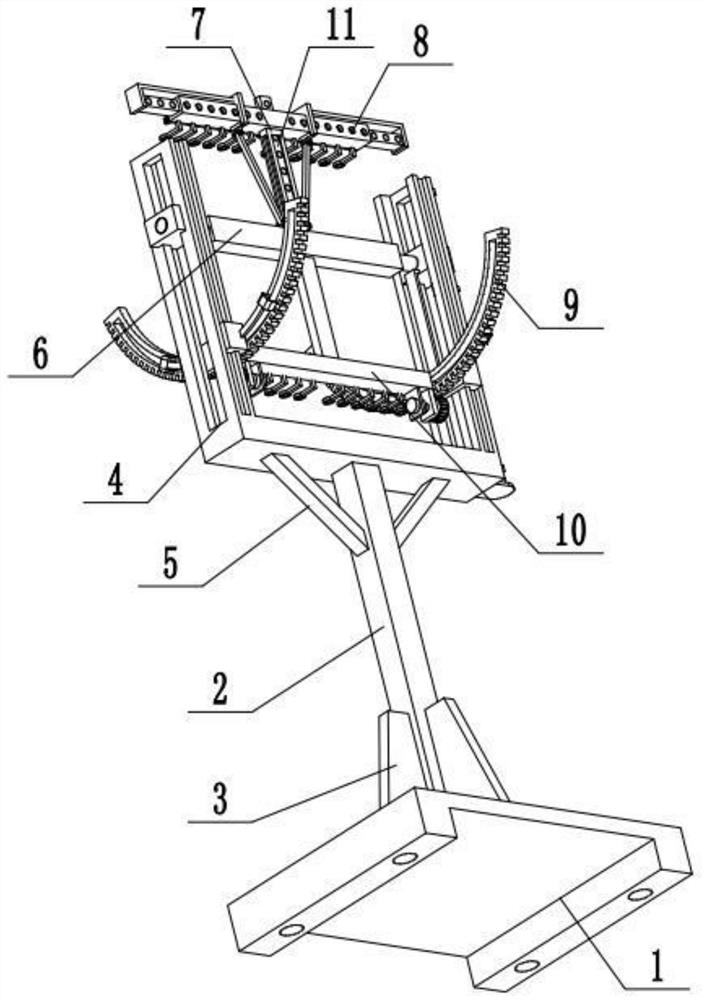

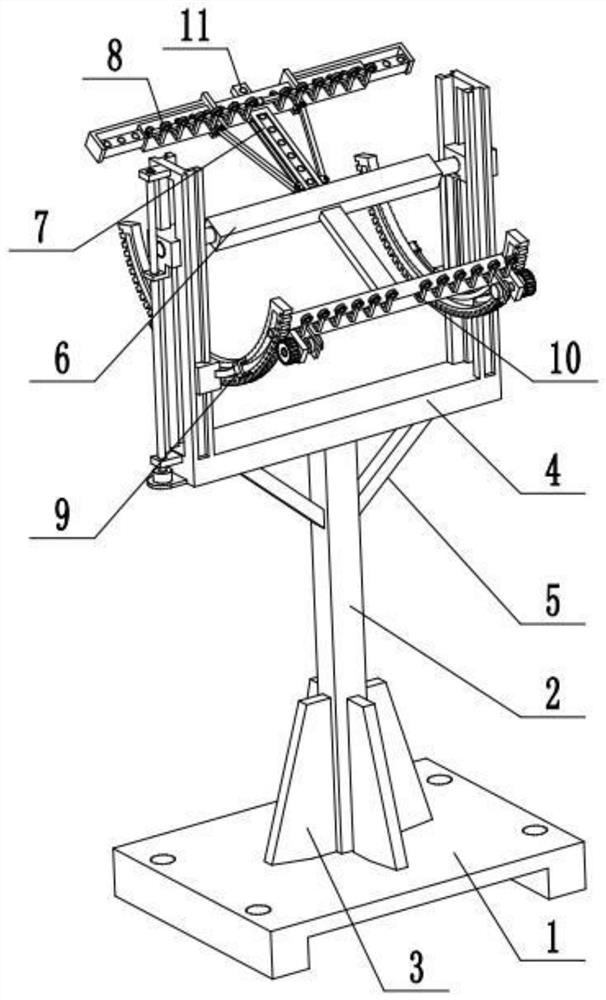

[0032] Combine below Figure 1-14 Describe this embodiment, a power line rack, including a base 1, a support rod 2, a rib plate 3, a height adjustment carriage 4, a diagonal rod 5, a height adjustment seat 6, a support slide frame 7, an upper fixing line assembly 8, an angle Adjust the sliding seat 9, the lower thread fixing assembly 10 and the auxiliary thread fixing assembly 11, the support rod 2 is fixedly connected to the base 1, the height adjustment carriage 4 is fixedly connected to the support rod 2, and the height adjustment seat 6 is slidably connected On the height adjustment carriage 4, the upper end of the height adjustment seat 6 is fixedly connected to the support slide frame 7, the upper wire fixing assembly 8 is fixedly connected to the support slide frame 7, the lower end of the height adjustment seat 6 is fixedly connected to the lower wire fixing assembly 10, and the lower end of the height adjustment seat 6 is fixedly connected to the lower wire fixing asse...

specific Embodiment approach 2

[0034] Combine below Figure 1-14 To illustrate this embodiment, the power line rack described further includes ribs 3 and oblique rods 5; the connection between the support rod 2 and the base 1 is uniformly surrounded and fixedly connected to four ribs 3, and the lower ends of the two oblique rods 5 are symmetrically fixed Connected to the support rod 2, the upper ends of the two oblique rods 5 are all fixedly connected to the height adjustment carriage 4. Four ribs 3 and two slanting rods 5 are used to increase the stability of the device, making the device more suitable for application environments.

specific Embodiment approach 3

[0036] Combine below Figure 1-9 To illustrate this embodiment, the height adjustment carriage 4 includes a bottom plate 4-1, a side plate 4-2, a side block chute 4-3, a rectangular through groove 4-4, a side chute 4-5, a motor I 4- 6. The lead screw 4-7 and the side frame plate 4-8; the bottom plate 4-1 is fixedly connected to the support rod 2, and the two ends of the bottom plate 4-1 are respectively fixedly connected to a side plate 4-2, and two side plates 4- A side block chute 4-3 is respectively arranged on the inner side of the 2, and a rectangular through groove 4-4 is respectively arranged on the two side plates 4-2; the rectangular through groove 4-4 and the side block chute 4-3 connected; the front and rear ends of the side plate 4-2 are respectively provided with a side chute 4-5; The plates 4-8 are all fixedly connected to the left side plate 4-2, the motor I4-6 is fixedly connected to the left side plate 4-2 through the motor frame, and the output shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com