Leather stretching and leveling device for leather product production

A technology for stretching and smoothing leather products, applied in the direction of leather wrapping/stretching, etc., can solve the problems that the leather smoothing effect is not ideal and cannot meet the needs of actual production and processing, and achieves the effect of improving the smoothing effect and high smoothing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

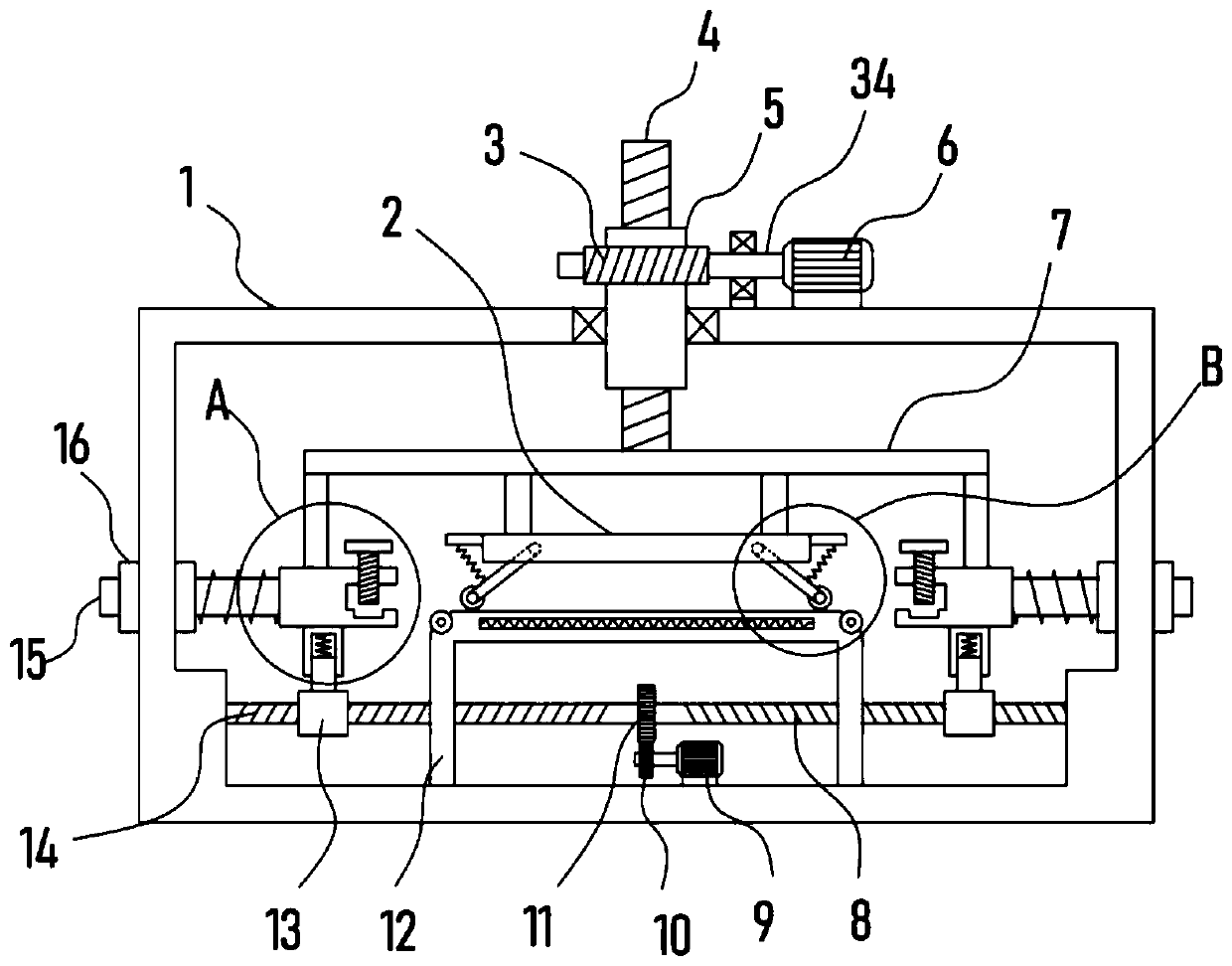

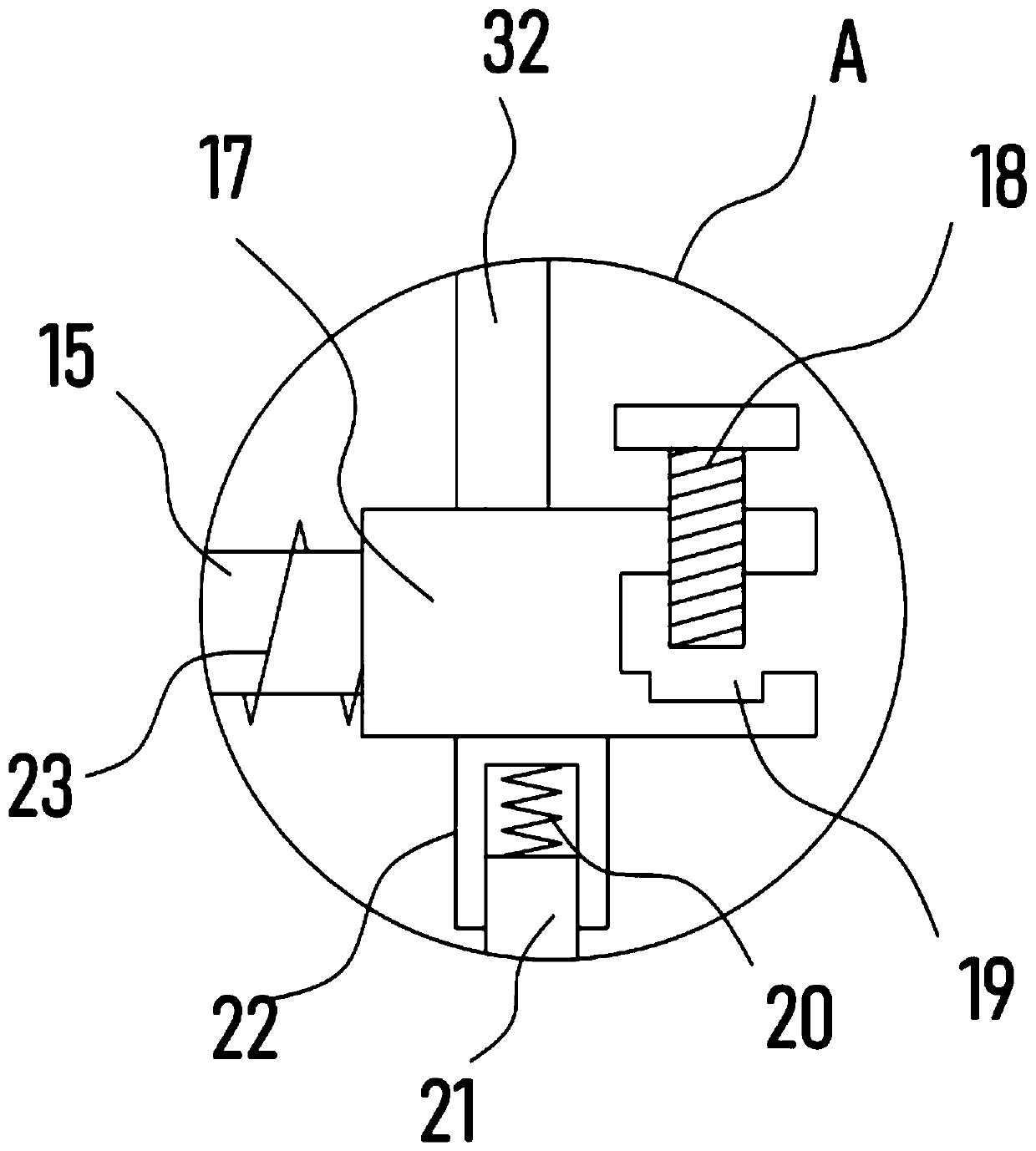

[0026] see Figure 1-6 , a leather stretching and leveling device for leather product production, comprising a support frame 1, a leveling platform 12 for supporting leather is fixedly installed on the support frame 1, and two clamps for clamping leather are arranged symmetrically on both sides of the leveling platform 12 Before performing leather leveling operation, the leather is clamped by the clamping mechanism, wherein the clamping mechanism includes a clamping groove block 17, and a vertical locking stud 18 is threaded on the clamping groove block 17 , the bottom of the clamping groove block 17 is fixed with a sleeve 22, and the sliding column 21 fixed with the threaded sleeve block 13 is slidably installed in the sleeve 22.

[0027] The two sides of the leather are clamped into the clamping groove block 17, and the locking stud 18 is screwed down until the leather is pressed and fixed in the clamping groove block 17. Further, there is a The compression slot 19 vertical...

Embodiment 2

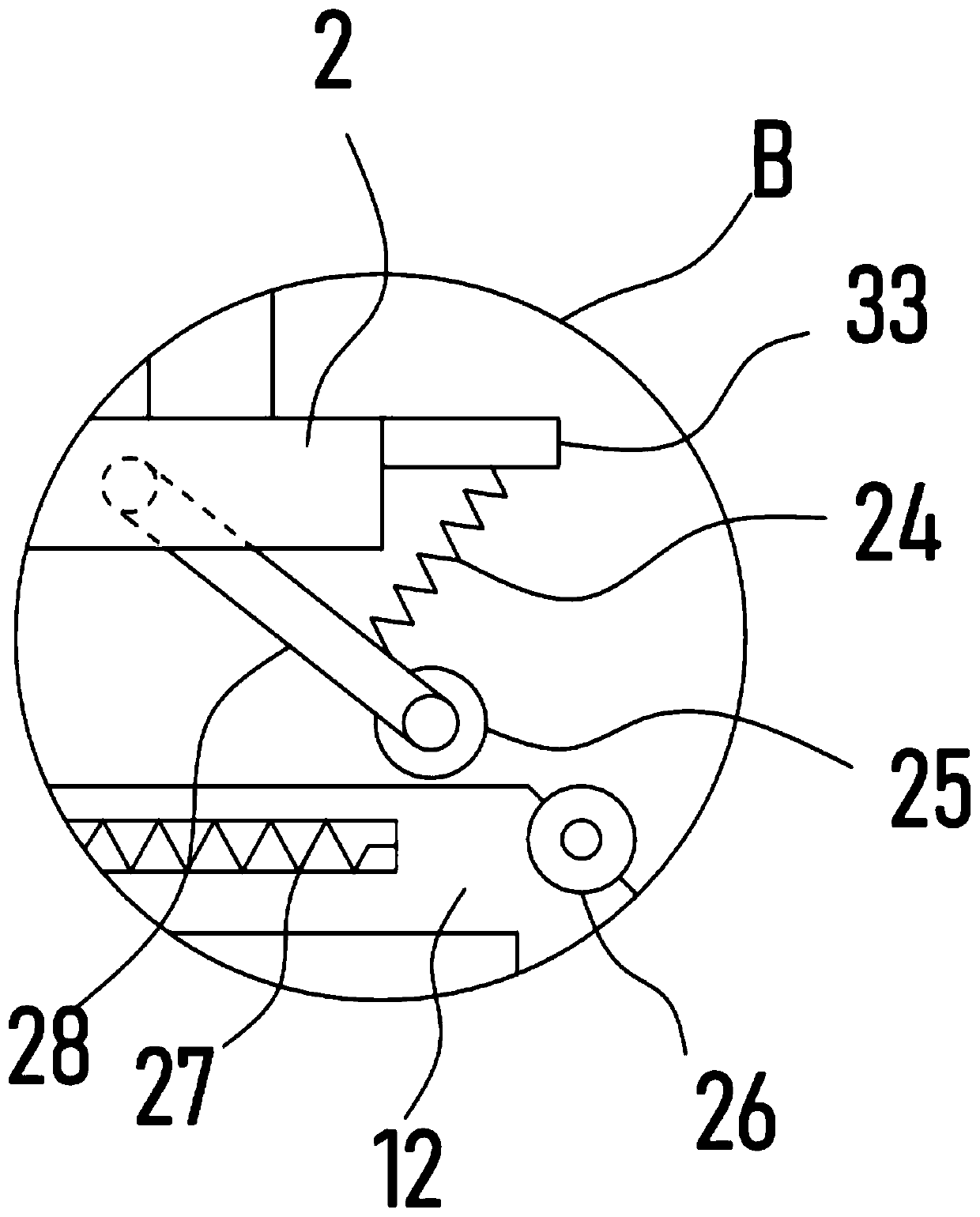

[0034] In order to further improve the leveling effect of the leather surface, on the basis of Embodiment 1, in addition, the bottom of the pressing plate 2 is horizontally provided with an accommodation groove 30, and a turret 28 is hinged in the accommodation groove 30, and a pressure roller 25 is rotatably arranged on the turret 28. An extension plate 33 is fixed on the side wall of the pressing plate 2 , and a return spring 24 is fixedly connected between the extension plate 33 and the turret 28 .

[0035] When the pressure plate 2 moves down, the pressure roller 25 touches the leather, and when the pressure plate 2 continues to press down, the turret 28 swings and deflects, and the pressure roller 25 rolls the leather to both sides of the leather, which promotes the stretching of the leather and To further smooth the leather, and the elastic action of the reset spring 24 provided on the turret 28 downward ensures that the pressure roller 25 has sufficient pressing force on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com