Floor odor-resistant floor drain with water-seepage-preventing clothing

A floor and floor drain technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve problems such as the inability to completely prevent gas leakage in building pipelines and easy water seepage to the bottom of the floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

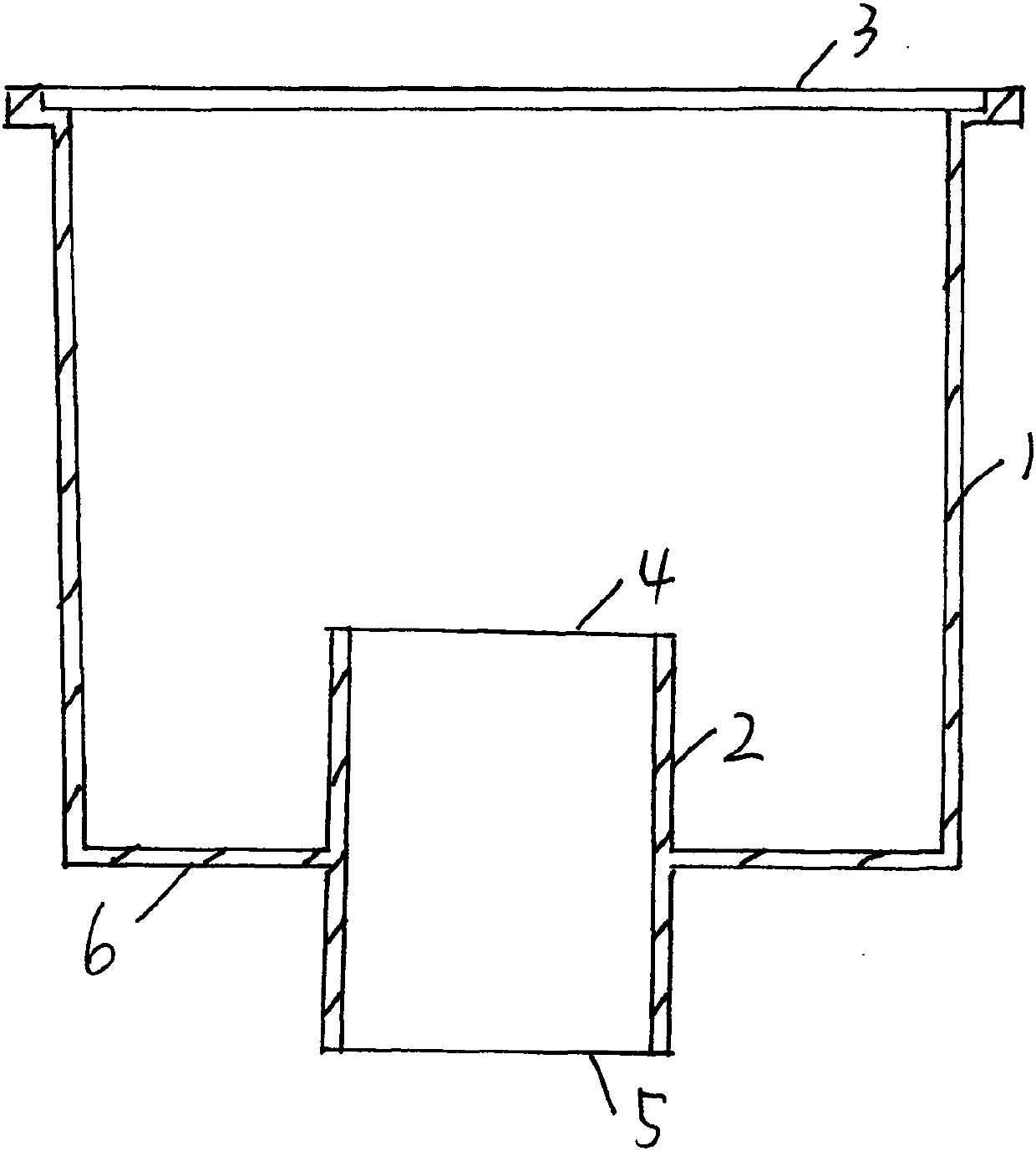

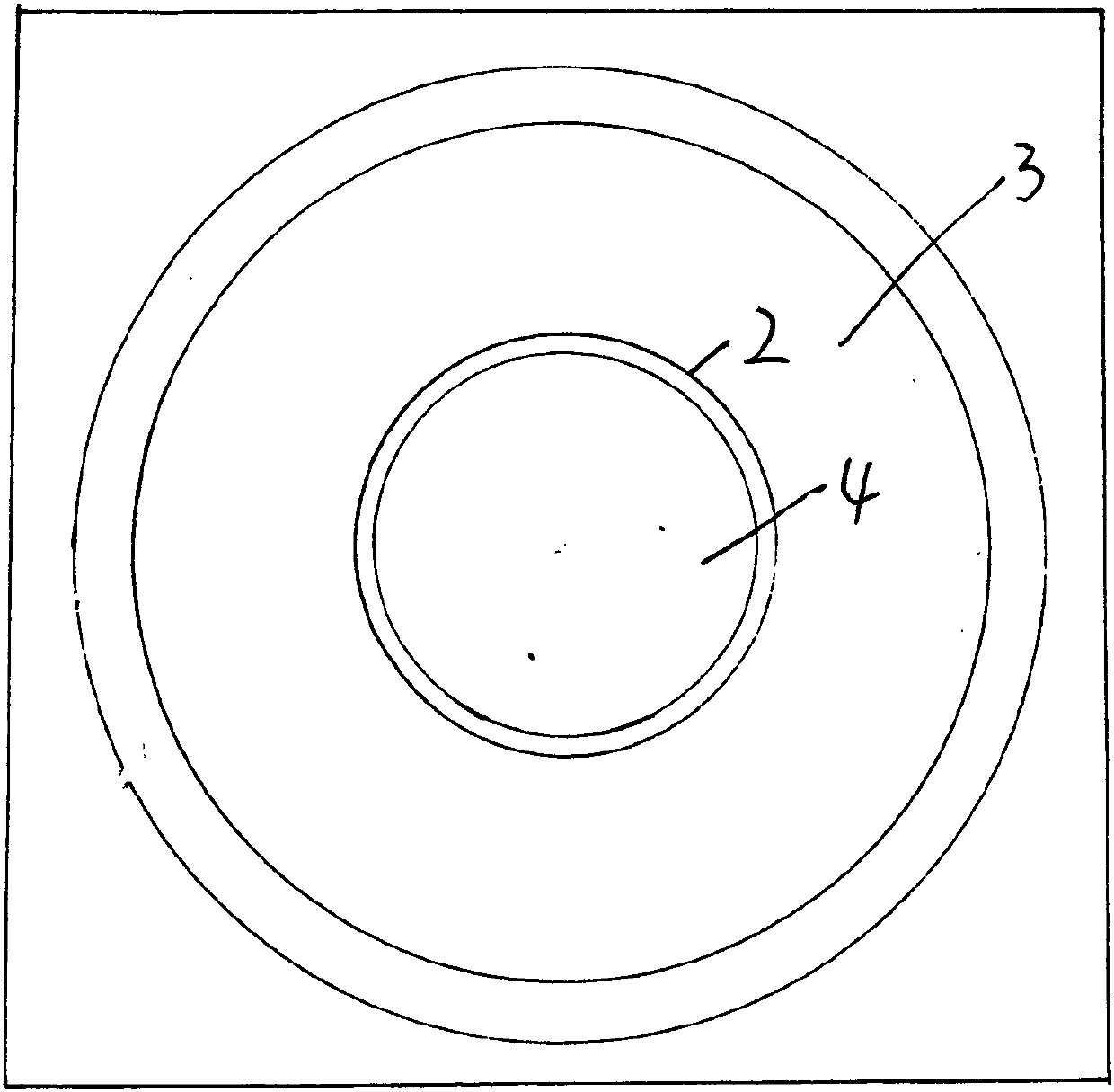

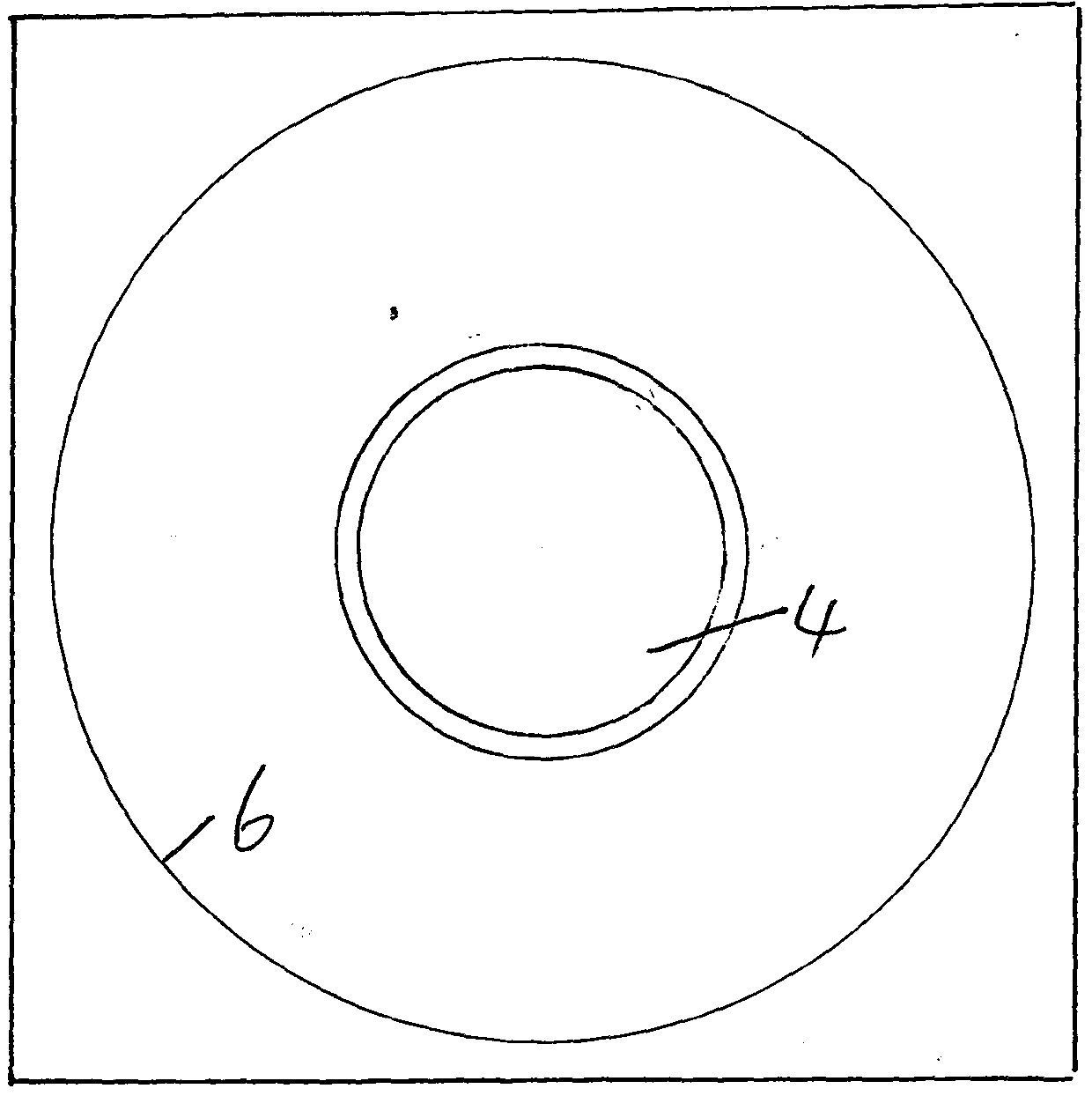

[0014] Step 1: Put a layer of glue on the whole body of the floor drain box, then put the floor drain jacket from the top of the waterproof jacket, put the waterproof jacket on the body of the floor drain box, the floor drain box and the waterproof jacket are integrated, When the anti-seepage clothing lifts up to the bottom of the end face of the floor drain box and can no longer be lifted up, put the water storage pipe outside the floor drain box into the building pipeline, then turn the anti-seepage clothing back down to the floor tile floor and soil surface, and put the anti-seepage Spread the skirt of the water jacket to cover the brick floor and the soil layer. The second step: bury the floor drain box to the end of the floor drain box with cement and other filling materials. The third step: insert the attached pipe into the water storage pipe in the floor drain box and then put the deodorant cover into the floor drain box to complete the first embodiment.

specific Embodiment approach 2

[0016] The first step and the second step are the same as the specific embodiment 1, and the third step: insert the outlet pipe of the n-shaped deodorant pipe into the internal water pipe of the floor drain box and connect it into one, and put the floor drain cover into the upper mouth of the floor drain box to complete the second embodiment.

[0017] The drawings mentioned above only show the structure, the shape and the size of each part are not drawn to scale, and are not limited to the illustrations. The material is metal, plastic, etc., and the process is stretching, elbow forming, stamping, injection molding, casting, etc. In order to facilitate processing, the anti-seepage clothing can be separated from the place where it turns back downwards, and is divided into two parts. During specific implementation, it is placed on the floor drain box in two steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com