Comprehensive rolling production line

A production line and comprehensive technology, applied in the direction of pressing rollers, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of complex processing technology, low efficiency, inconvenient production and manufacturing, etc., to ensure the quality of folding edges, and it is not easy to shift left and right. , to avoid the effect of edge fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

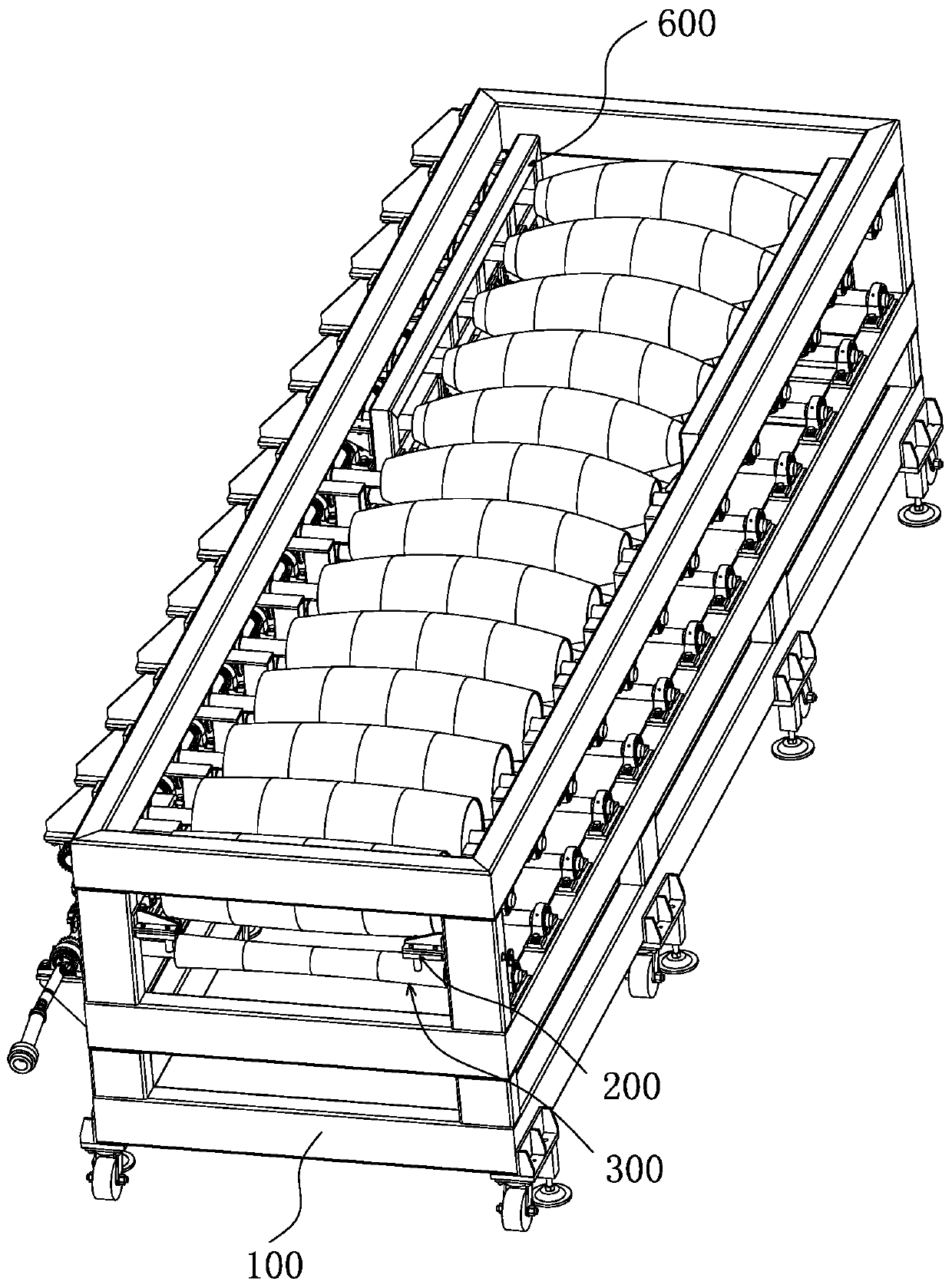

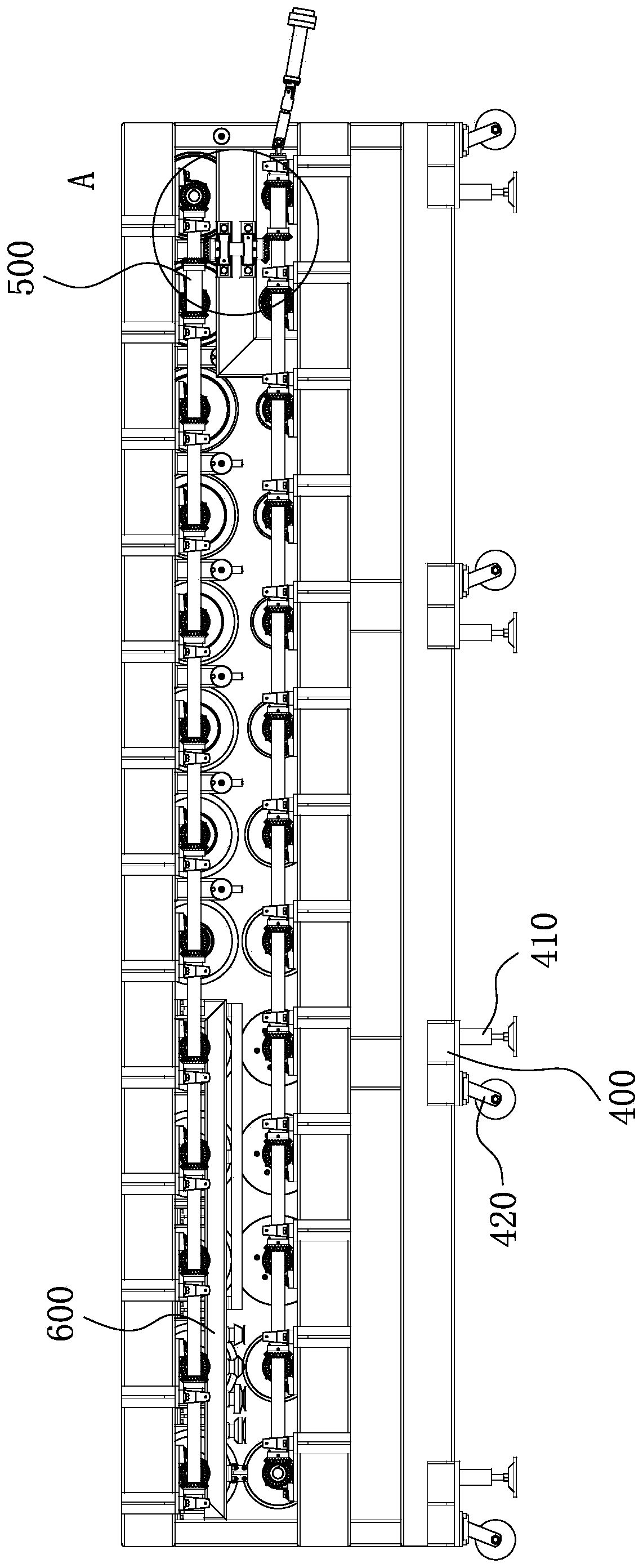

[0037] like Figure 1 to Figure 10 As shown, this comprehensive rolling production line includes:

[0038] Rack 100;

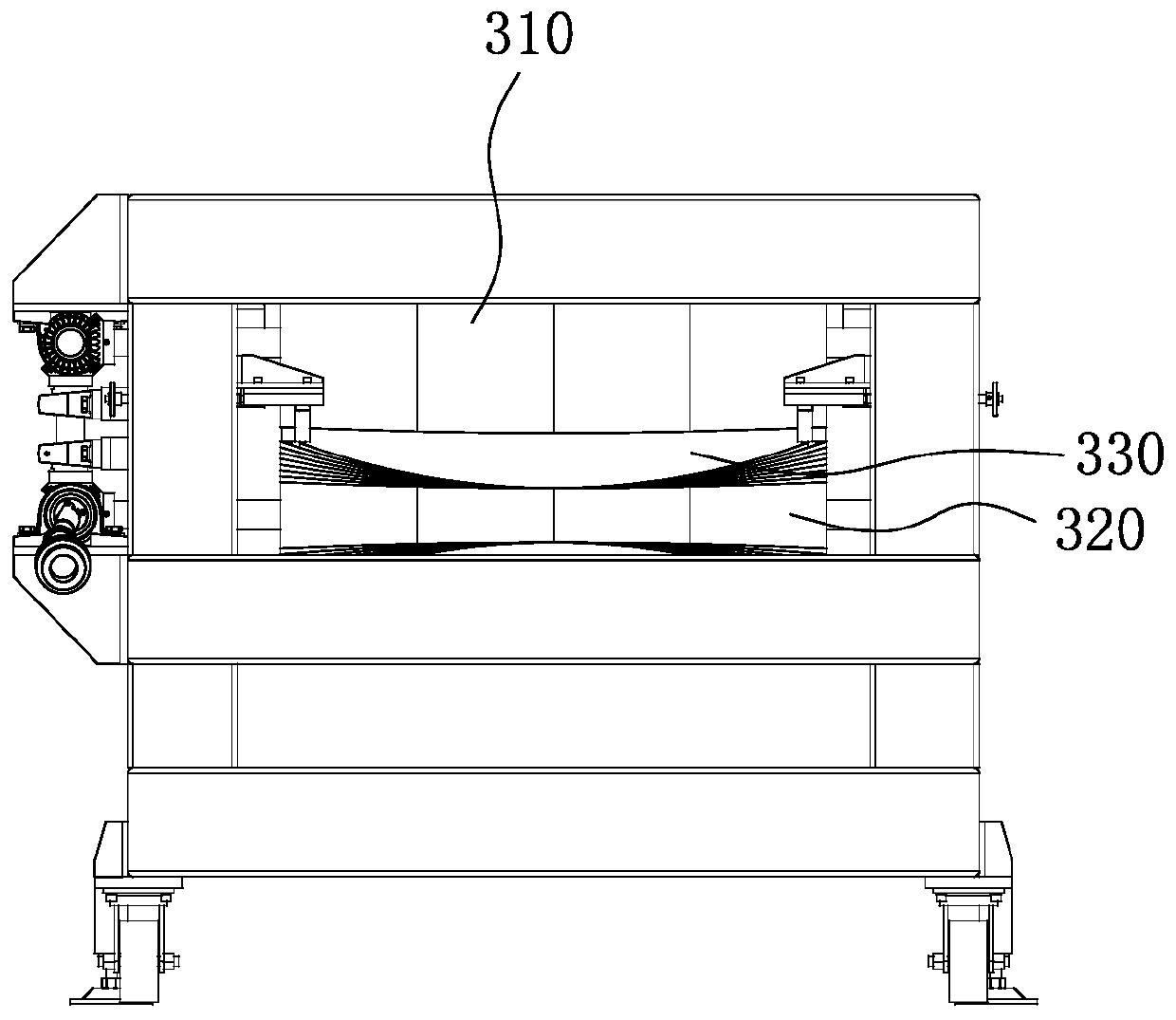

[0039] Several groups of rolling assemblies 300 are installed on the frame 100 and arranged evenly along the horizontal direction. Each group of rolling assemblies 300 includes upwardly convex arc-shaped rollers 310 and downwardly concave arc-shaped rollers 320 correspondingly arranged up and down. The upwardly convex arc-shaped rollers Between 310 and the concave arc-shaped roller 320, there is a rolling channel 330 for the workpiece to pass through;

[0040] The hemming assembly 600 is installed on the left or right side of the frame and extends into the rolling channel, and the hemming assembly 600 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com