Lid pulling and pressing device of sterile filling machine

A filling machine and capping technology, which is applied to electric operating devices, tightly capping containers with lids, packaging, etc., can solve problems such as bottle cap scratches, affecting the appearance of manufactured products, wasting human resources, etc., to ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the content of the present invention is not limited to the following embodiments.

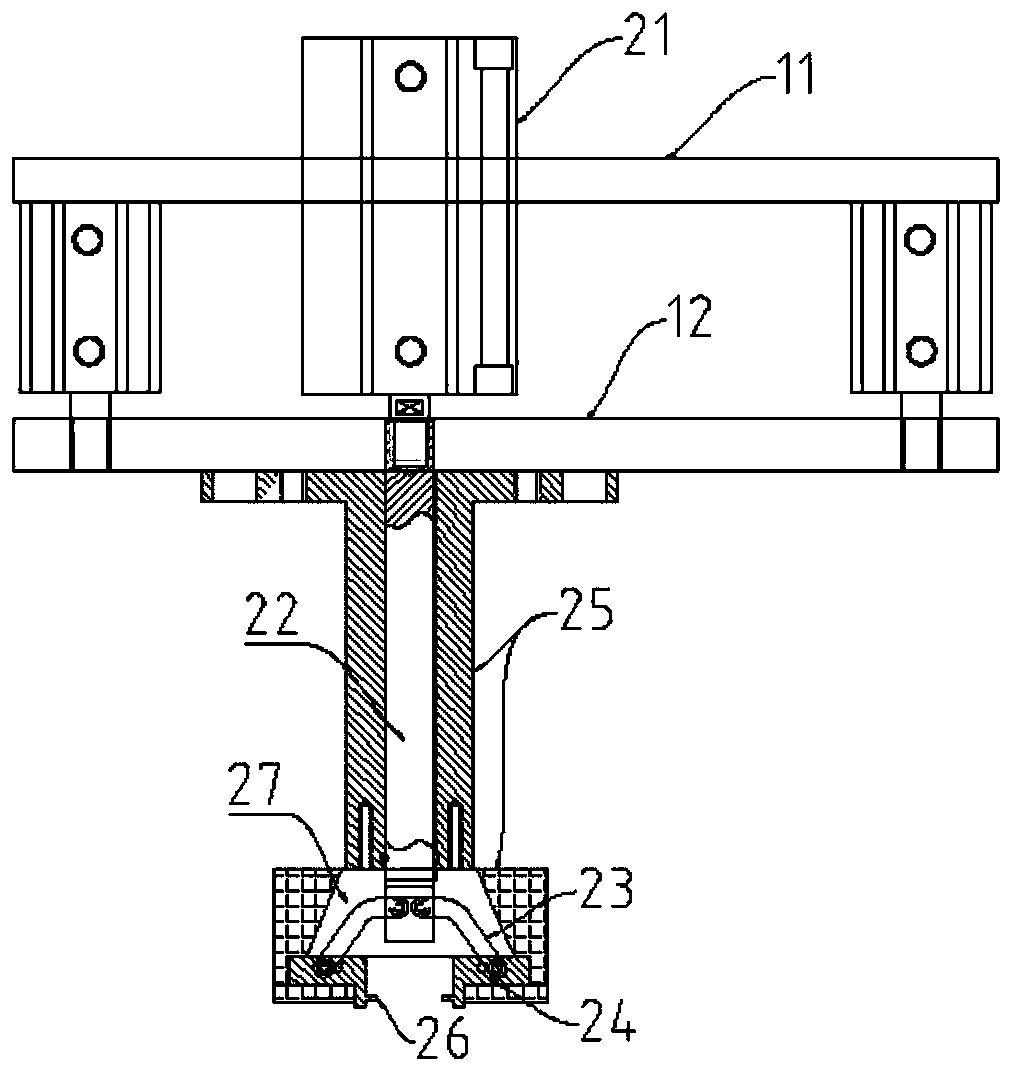

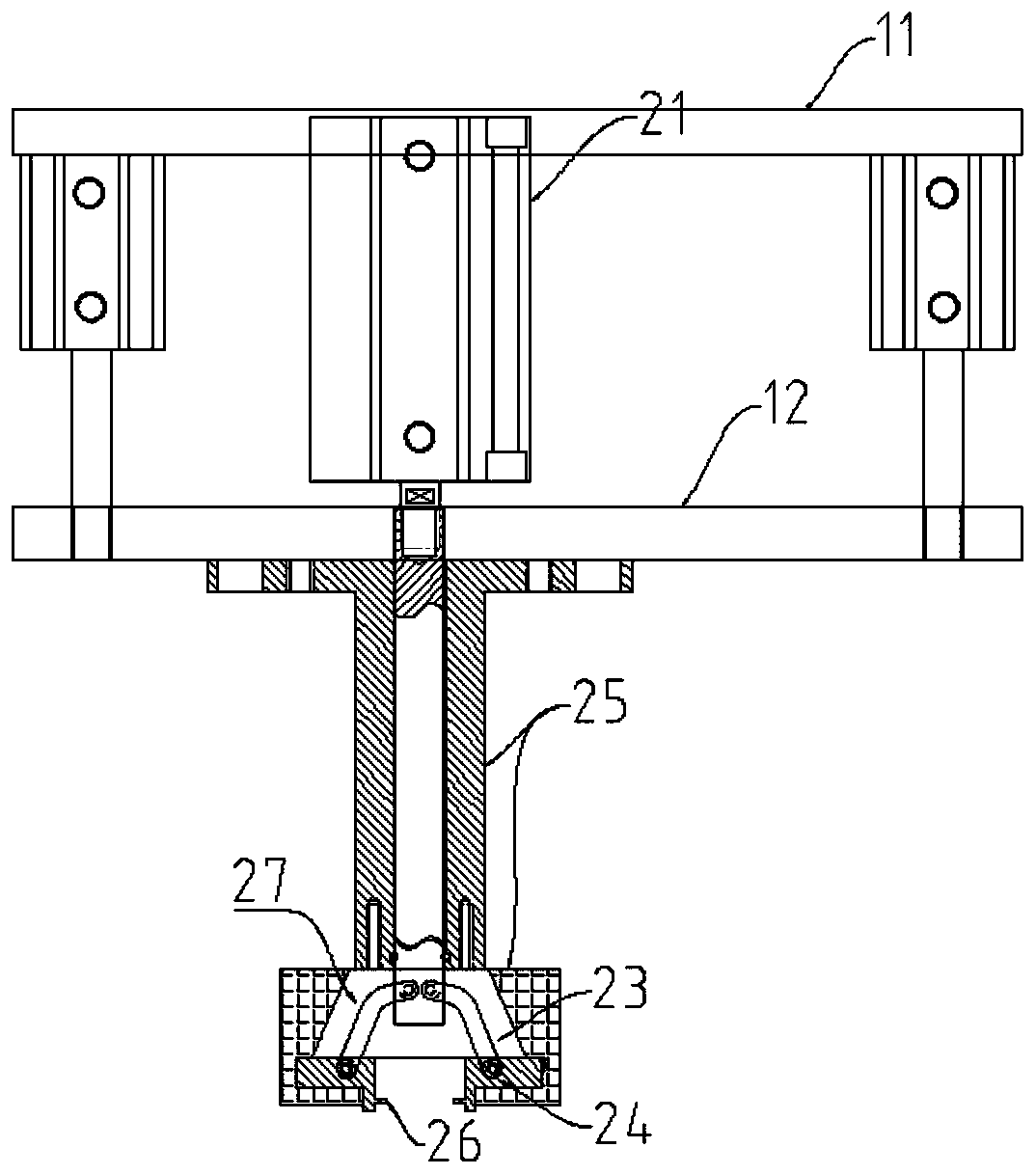

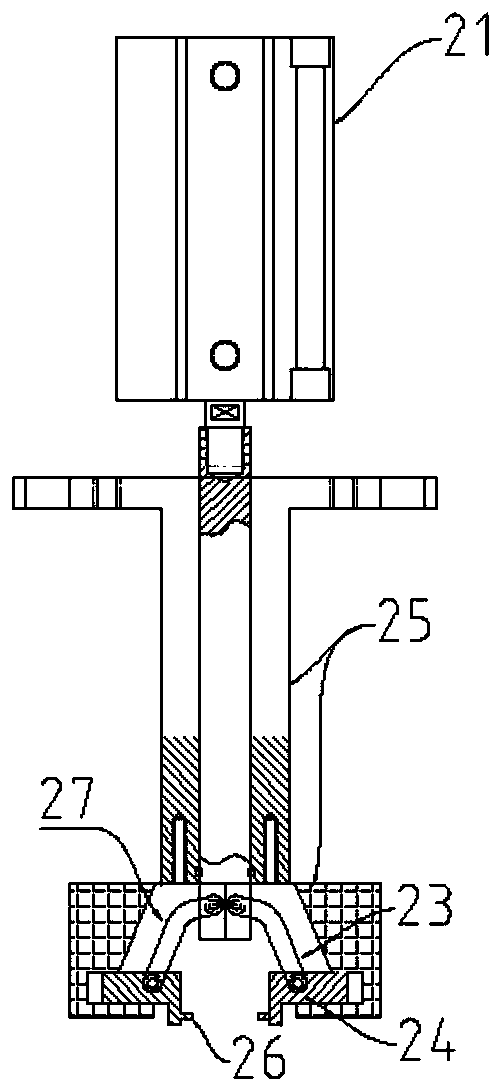

[0035] The invention provides a cap pulling and capping device for an aseptic filling machine, which includes a bottle cap clamping mechanism and a first driving device,

[0036] The bottle cap clamping mechanism is in drive connection with the driving end of the first driving device, and is driven by the driving device to reciprocate up and down,

[0037] The clamping end of the bottle cap clamping device is used to clamp the side of the bottle cap.

[0038] The clamping end of the cap pulling and cap pressing device of an aseptic filling machine provided by the present invention is different from the traditional way of clamping the cap from the upper end of the bottle cap, and the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com