A device and method for detecting verticality of wall column formwork

A detection device and verticality technology, which is applied in the direction of plumb line, fixed angle, etc., can solve the problems that the instrument cannot measure data accurately, the operating space is limited, and the regional data is blank, so as to promote fast standing and increase work Efficiency, the effect of reducing the number of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

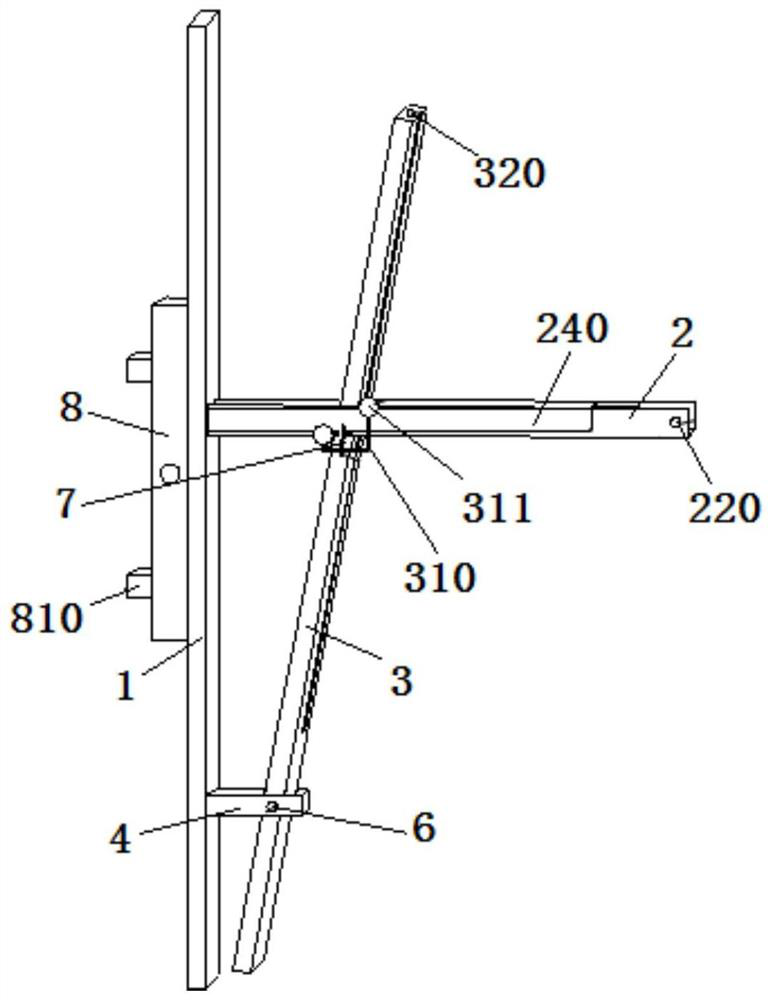

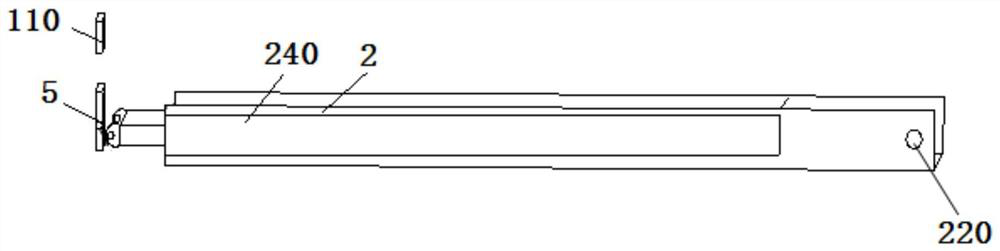

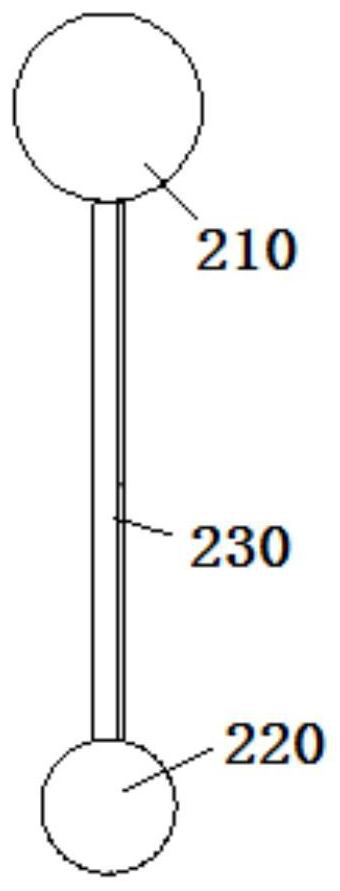

[0037] like Figure 1 to Figure 5 As shown, a verticality detection device for a wall stud formwork includes a vertical rod 1, a horizontal ruler 2, a vertical ruler 3, an extension rod 4, a first shaft locking mechanism 5, a second shaft locking mechanism 6 and a trimmer 7, and the vertical rod 1 is arranged vertically, and the horizontal ruler 2 is arranged horizontally. The left end of the horizontal ruler 2 is connected to the vertical rod 1 through the first lock shaft mechanism 5, the right end of the horizontal ruler 2 is the movable end, and the front side and / or the rear side of the horizontal ruler 2 There is a transparent ruler surface 240 on the top; the extension rod 4 is arranged under the horizontal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com