Anti-wave plate device for liquid tank box

A technology of anti-wave board and tank container, which is applied in the directions of packaging, transportation, packaging, containers, etc. It can solve the problems of weak effect and small effective area of anti-wave board, and achieve good anti-wave effect, convenient installation and subsequent maintenance, and guarantee Anti-sloshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

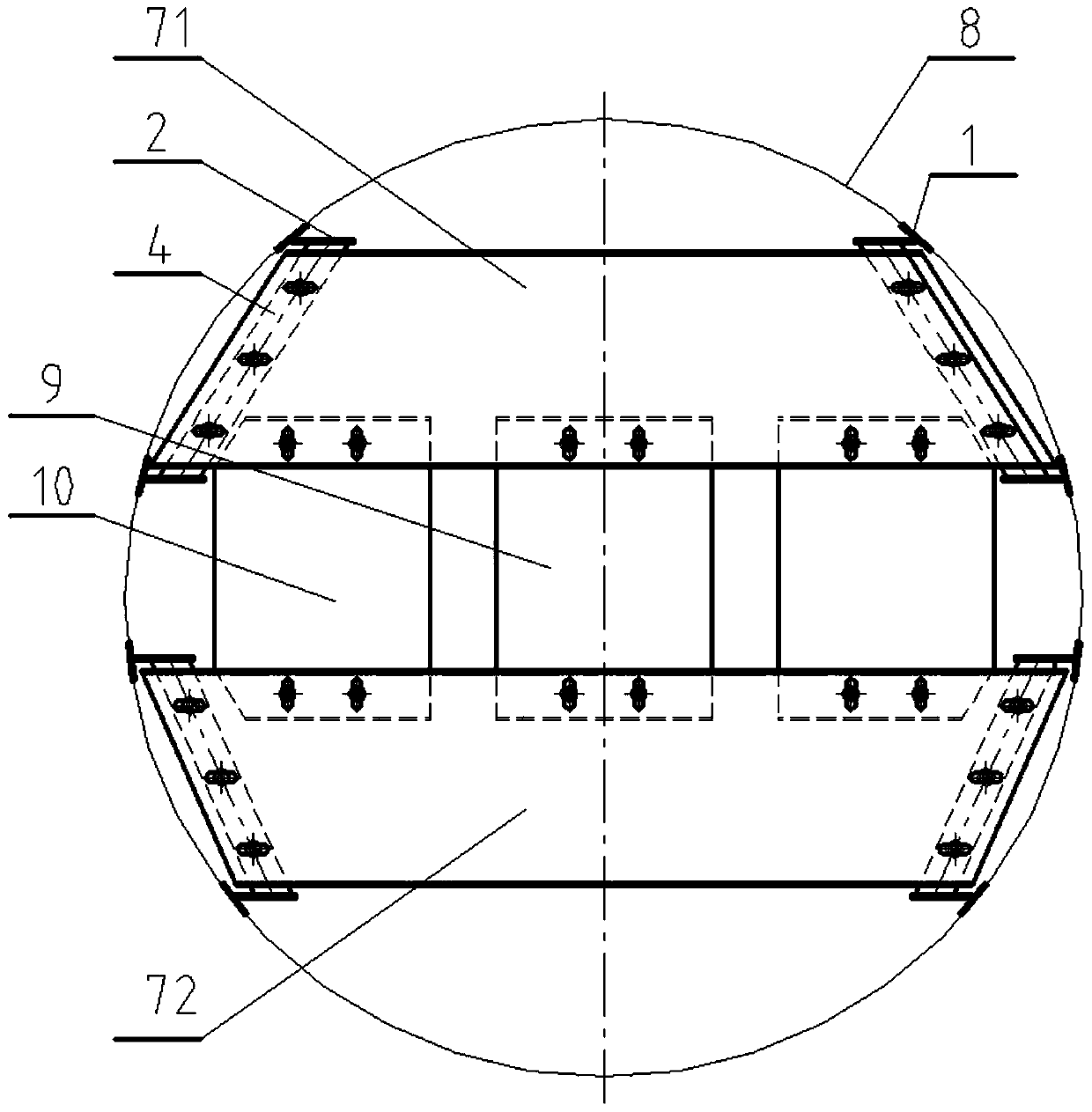

[0038] as attached figure 1As shown, a wave-proof plate device for liquid tanks, whose tank body is marked as 8, includes first wave-proof plates 71, 72, wherein 71 is the first wave-proof plate, and 72 is the first wave-proof plate The lower plate includes the second wave-proof plate 9, 10, the first wave-proof plate 71, 72 is fixedly connected to the tank body 8, and spans the section of the tank box, the upper plate 71 and the lower plate of the first wave-proof plate 72 are arranged side by side on the cross section of the tank, and the two ends of the second anti-wave plates 9, 10 are respectively connected and fixed on the first anti-wave plates 71, 72 to fill the gap between the first anti-wave plates 71, 72 .

Embodiment 2

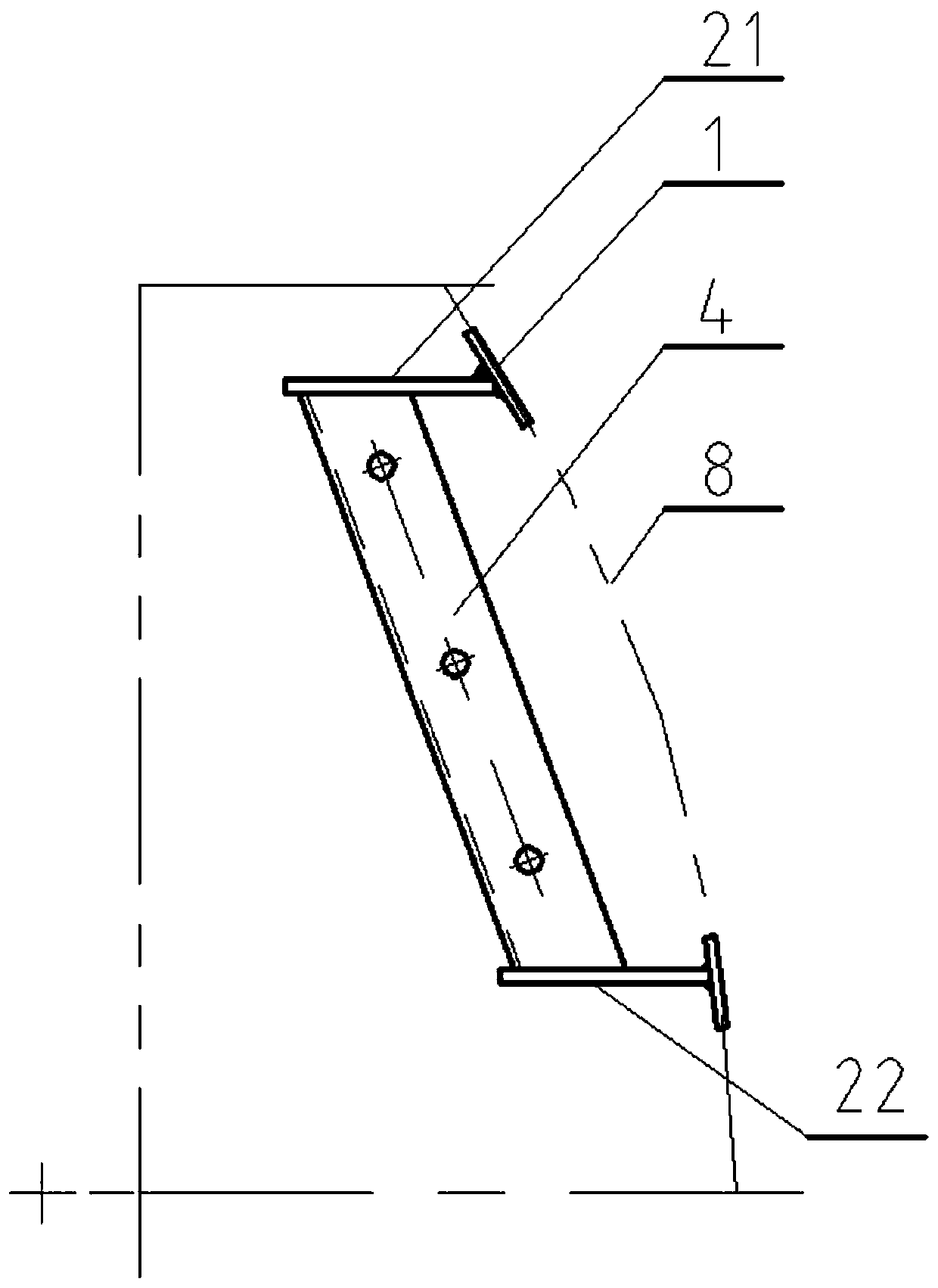

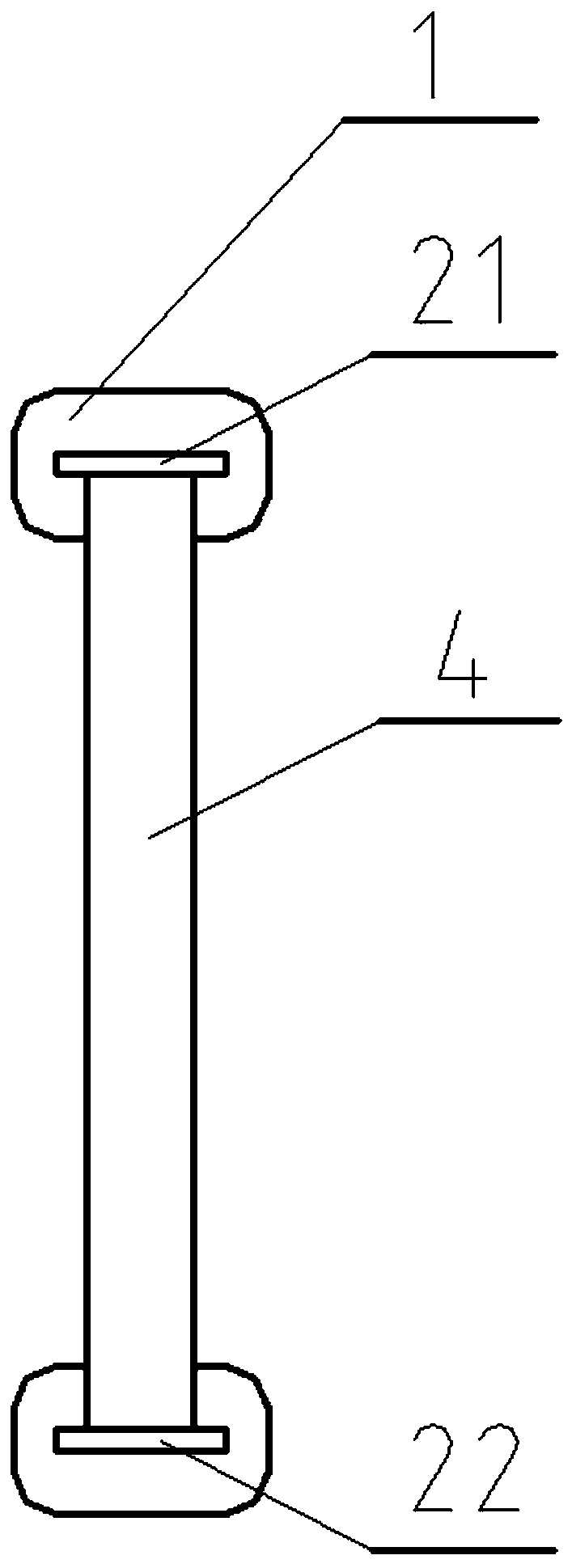

[0040] as attached figure 1 , attached figure 2 , attached image 3 As shown, the anti-wave plate device for liquid tanks also includes a backing plate 1, a column 2 and a support plate 4, the shape of the backing plate 1 is adapted to the inner wall 8 of the tank box, and the backing plate 1 and the inner wall 8 of the tank box are welded and fixed , one end of the column 2 is welded to the backing plate 1, the column body of the column 2 is welded to fix the support plate 4, and the support plate 4 is supported and fixed by at least two columns 21, 22, and the first anti-wave The plates 71, 72 are parallel to the support plate 4, and the support plate 4 is provided with a through hole, and the first anti-wave plates 71, 72 are fixedly connected with the support plate 4 through bolts and nuts.

Embodiment 3

[0042] as attached Figure 4 As shown, the column 2 is in the shape of a vertical plate, the right end of the column 2 is welded to the backing plate 1, and the column body of the column 2 is welded to fix the support plate 4, the support plate 4 is an angle steel plate, the angle steel plate is bent, and one end is welded to fix the column , one end is provided with a through hole, the first wave-proof plate 7 is also provided with a through-hole, the bolt 3 passes through the angle plate through-hole, the wave-proof plate through-hole in turn, cooperates with the nut 6, the angle plate and the wave-proof plate are fixed, in addition, Flat washers 51 and 52 are also provided to increase the contact area between bolts or nuts, angle steel plates and anti-wave plates, and prevent bolts or nuts from easily slipping off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com