A device for assembling the main load-bearing frame of an engine thrust reverser

A technology of reverse thrust device and main bearing force, which is applied in the field of devices for assembling sheet metal parts, which can solve the problems of difficult assembly, difficulty in ensuring the accuracy of assembly size and positional relationship, etc., to reduce assembly difficulty, increase assembly speed, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other implementations obtained by persons of ordinary skill in the art without making creative efforts fall within the protection scope of the present invention.

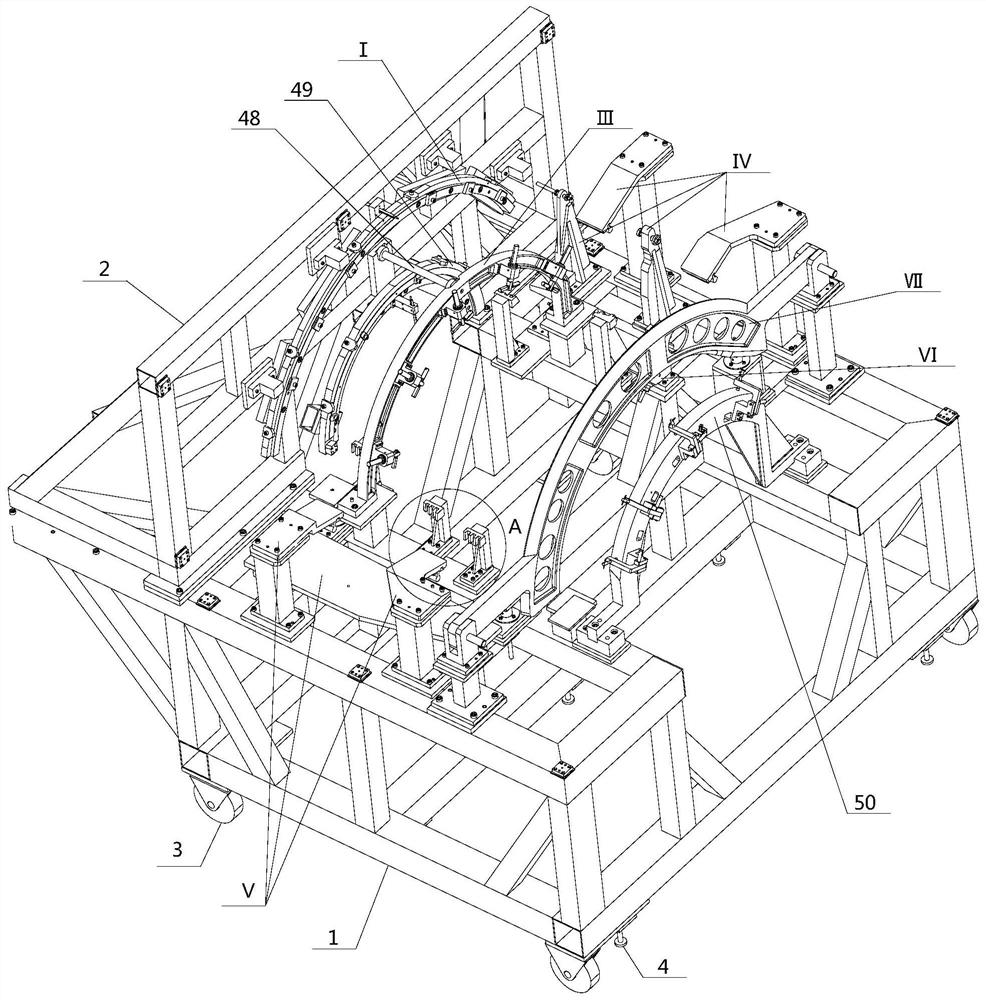

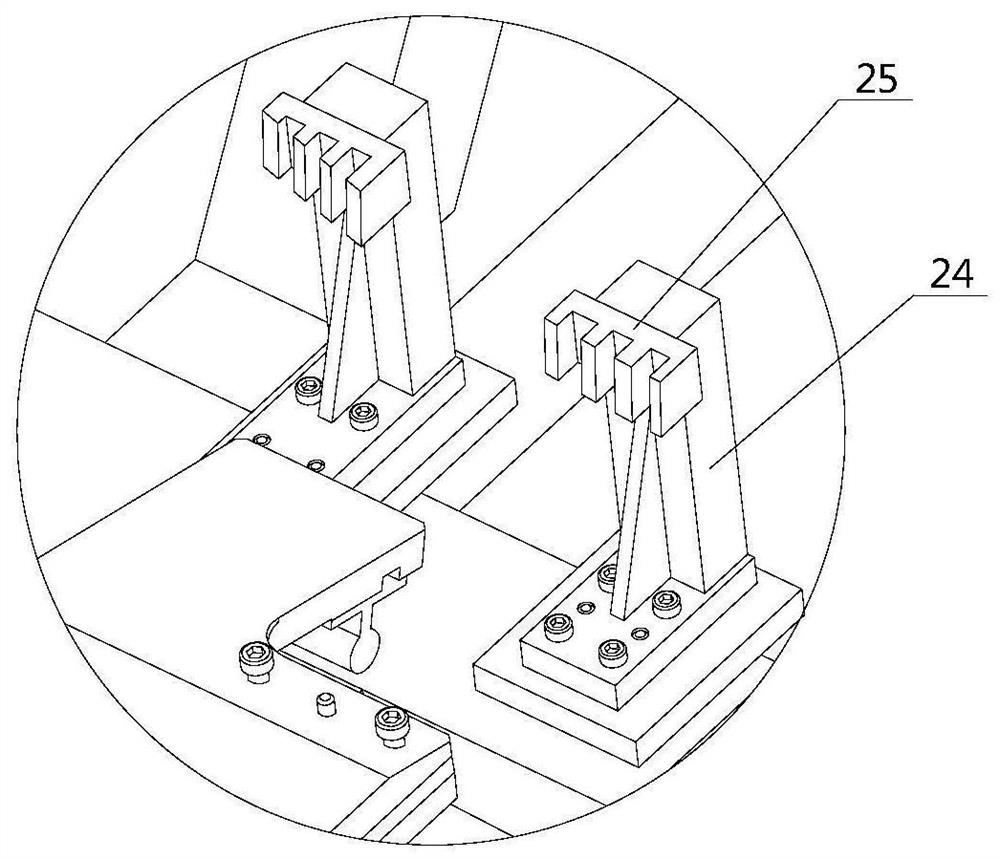

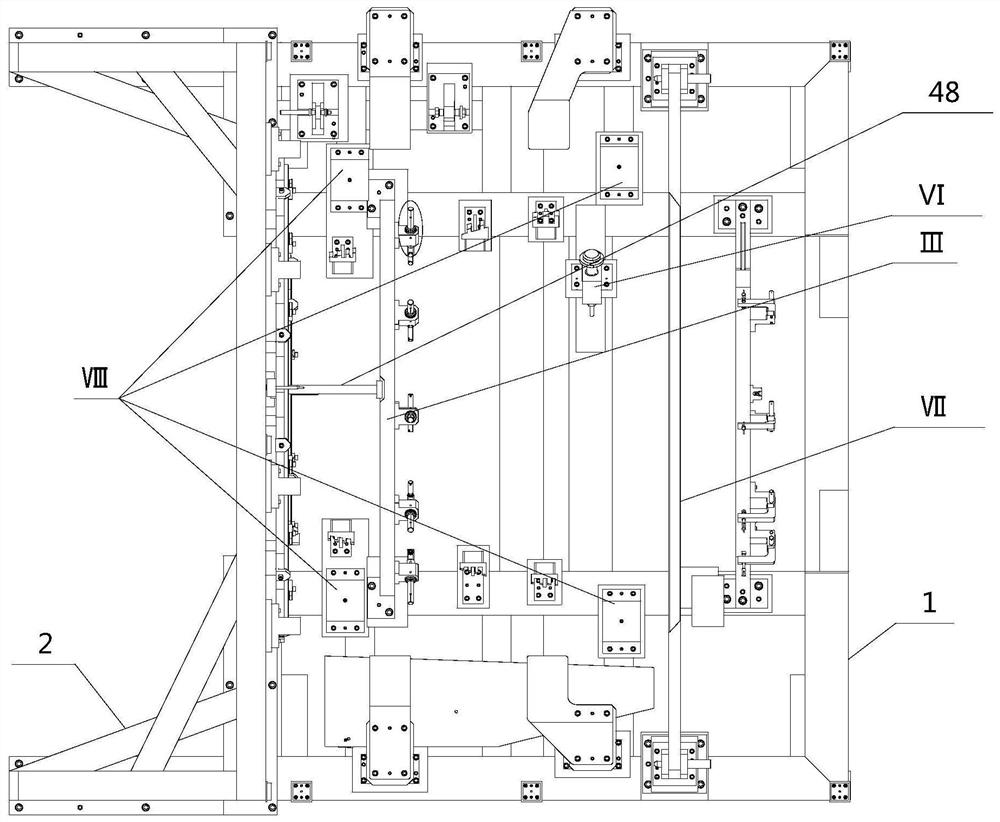

[0074] like Figure 1-Figure 22 Shown:

[0075] The present invention provides a device for assembling the main load-bearing frame of the engine thrust reverser, including a bracket, and the bracket is provided with a torque box assembly positioning mechanism I for fixing the main load-bearing frame torque box assembly 54, for Outer culvert and inner wall assembly positioning mechanism II for fixing the outer culvert inner wall assembly 55 of the main load-bea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap