Tube-type line strander

A stranding machine, tubular technology, used in auxiliary equipment for rope making, textile and paper making, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

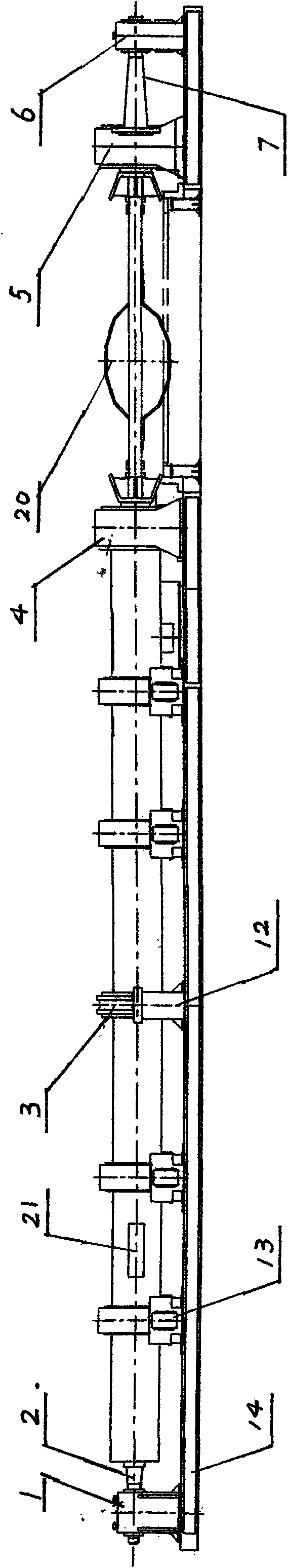

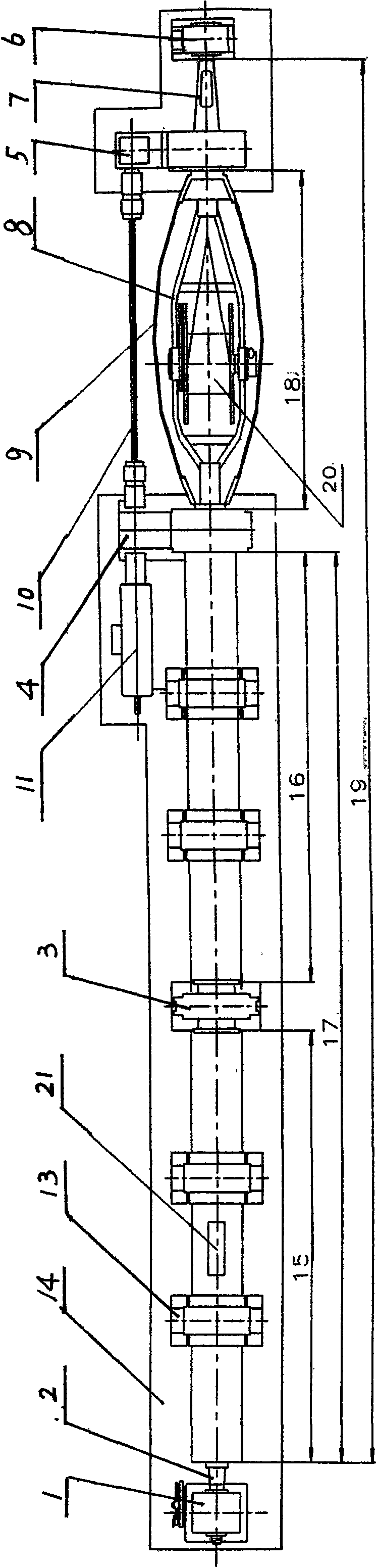

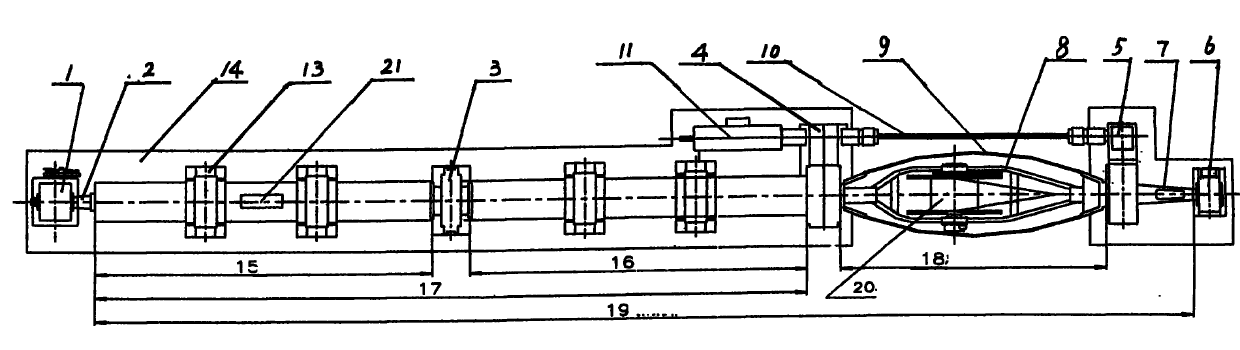

[0022] see figure 1 , figure 2 : This tubular stranding machine mainly includes a machine base 14, a rotating strand 19, a gear transmission box 4,5, and a drive motor 11, and the rotating strand 19 is supported on a support shaft 2,7 by supporting shafts 2,7 at both ends of the head and tail. On the seats 1 and 6, the support seats 1 and 6 are fixed on the machine base 14, driven by the motor 11, and transmitted by the gear transmission box 4, 5, so that the rotating twisted body 19 is rotated; the machine base 14 is arranged with multiple brackets The wheel assembly 13 is distributed longitudinally along the base 14 and is supported on the waist of the rotating twisted body 19 . A plurality of circumferential wire pay-off reels 21 are arranged in the rotating twisted body 19 .

[0023] The characteristic of this tubular stranding machine is that the rotating stranding body 19 is composed of cylinder body 15, 16 and double-bow type wire reel support body 18. The cylinder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com