Fastening sand tooling and turbine casing casting system

A turbine shell and sand mold technology, which is applied to casting molding equipment, cores, molds, etc., can solve the problems of sand mold cracking and leaking molten iron, turbine shell sand mold cracking, and leaking molten iron, etc., to solve cracking, ensure casting quality, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

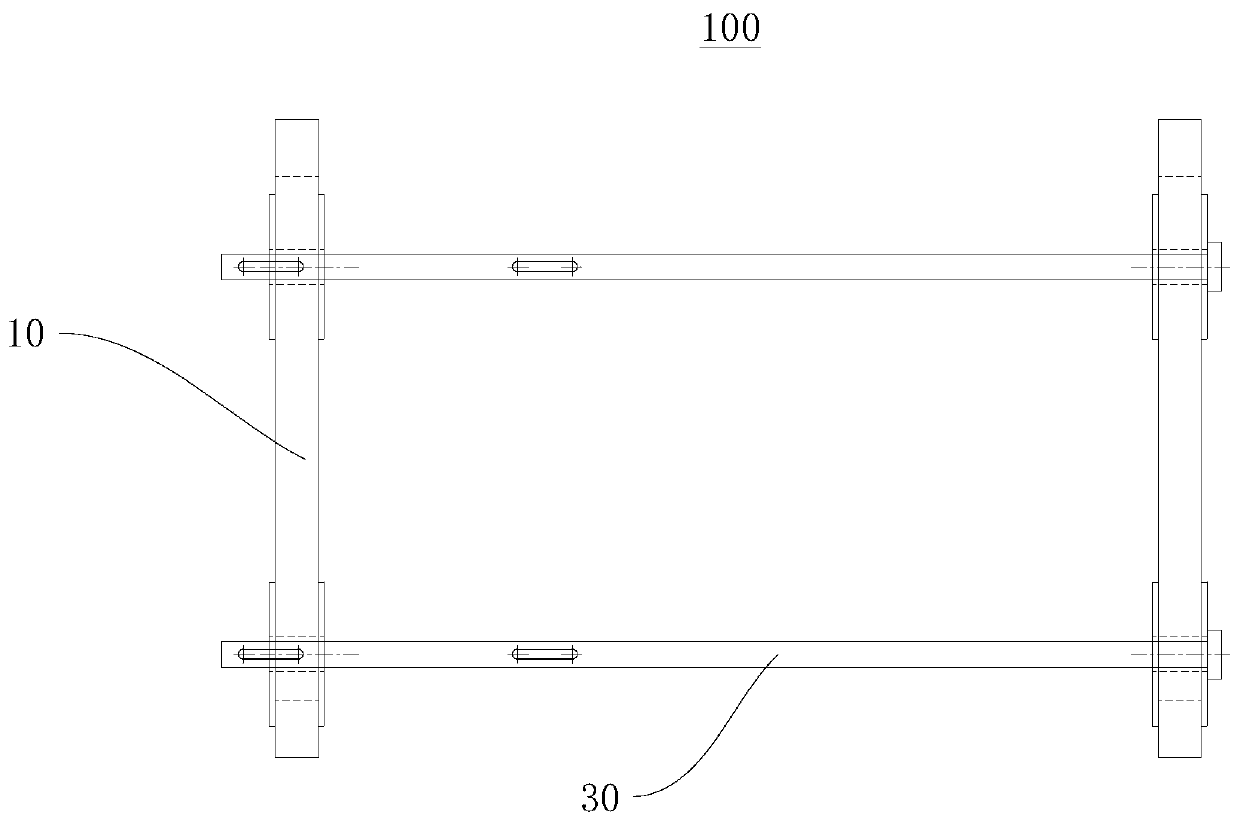

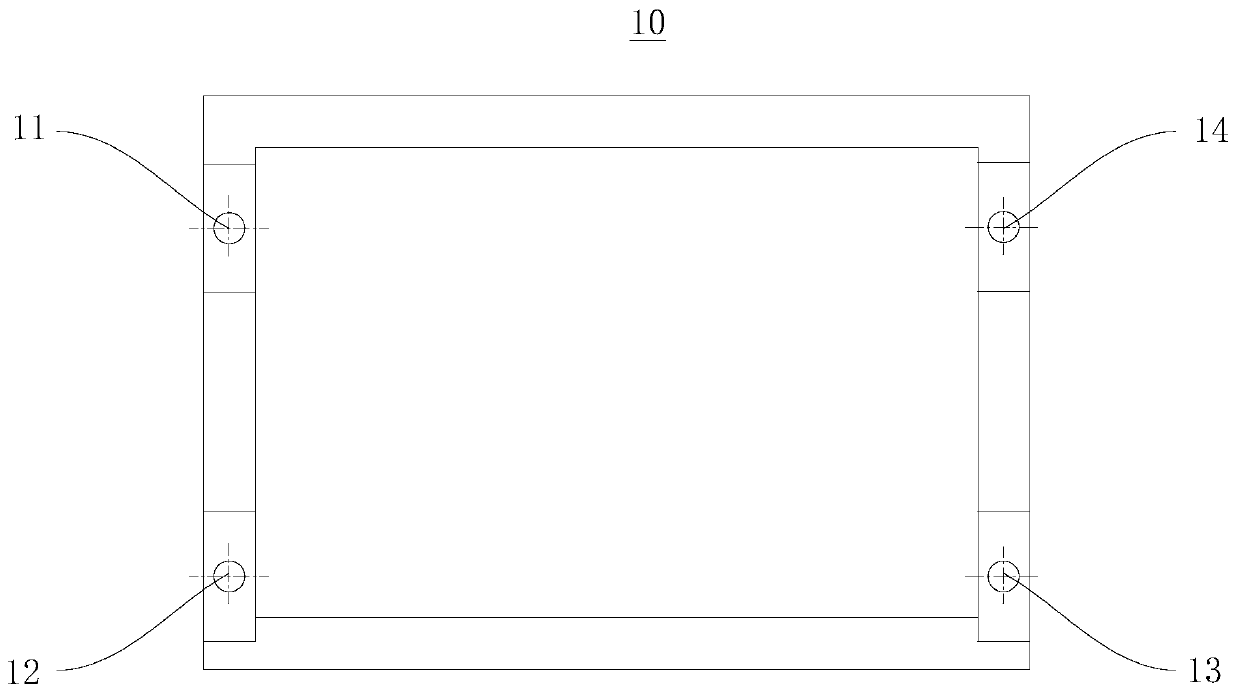

[0040] Please refer to figure 1 , the present embodiment provides a sand mold fastening tool 100, including a pressing frame 10, a connecting rod 30 and a fixing pin.

[0041] Specifically, please combine Figure 2 to Figure 7 . The pressing frame 10 is used to be arranged on both sides of the sand mold in the horizontal direction, and the pressing frame 10 has at least two connection holes and is respectively located on opposite sides of the pressing frame 10 .

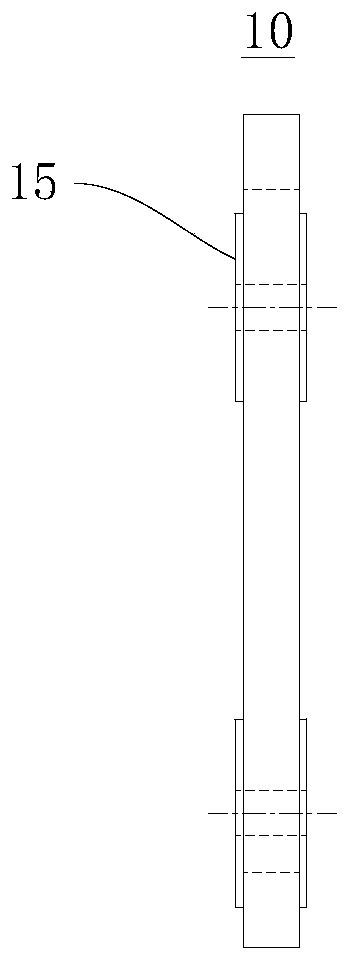

[0042] The connecting rod 30 includes a limiting end 31 and a rod body 33 , the limiting end 31 is disposed at one end of the rod body 33 , and the rod body 33 has a pin hole. When press-fitting the sand mold, the connecting rod 30 is passed through the connection holes of the compression frame 10 on both sides of the sand mold, the limit end 31 is located on the side of one of the compression frames 10 away from the sand mold, and the pin hole is located on the other side of the compression frame 10. On the side ...

Embodiment 2

[0073] This embodiment provides a turbine casing casting system, including a turbine casing sand mold 101 and the fastening sand mold tooling 100 in Embodiment 1.

[0074] The fastening sand mold tooling 100 clamps and fixes the turbine casing sand mold 101 in the horizontal direction. The sizes of the used pressing frames 10 , connecting rods 30 and fixing pins are determined according to the turbine casing sand mold 101 .

[0075] like Figure 8 As shown, the fastening sand mold tooling 100 can also press-fit three turbine shell sand molds 101 at the same time, which is more conducive to increasing the output for the manufacture of the same type of turbine shell.

[0076] By adopting the fastening sand mold tooling 100 in Embodiment 1, the turbine casing casting system can perform the casting work of the turbine casing with quality and quantity, improve the casting quality and efficiency, and benefit the production efficiency of the enterprise.

[0077] In summary, the fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com