Slow decent receiving mechanism and method used for flaky materials

A technology of receiving mechanism and lifting mechanism, applied in stack receiving device, thin material handling, packaging, etc., can solve the problems of inconsistent stacking uniformity of upper and lower layers, large falling distance of sheet materials, scattered sheet materials, etc., to avoid The effect of turning over sheet materials, improving stacking uniformity, and stacking neatly and consistently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

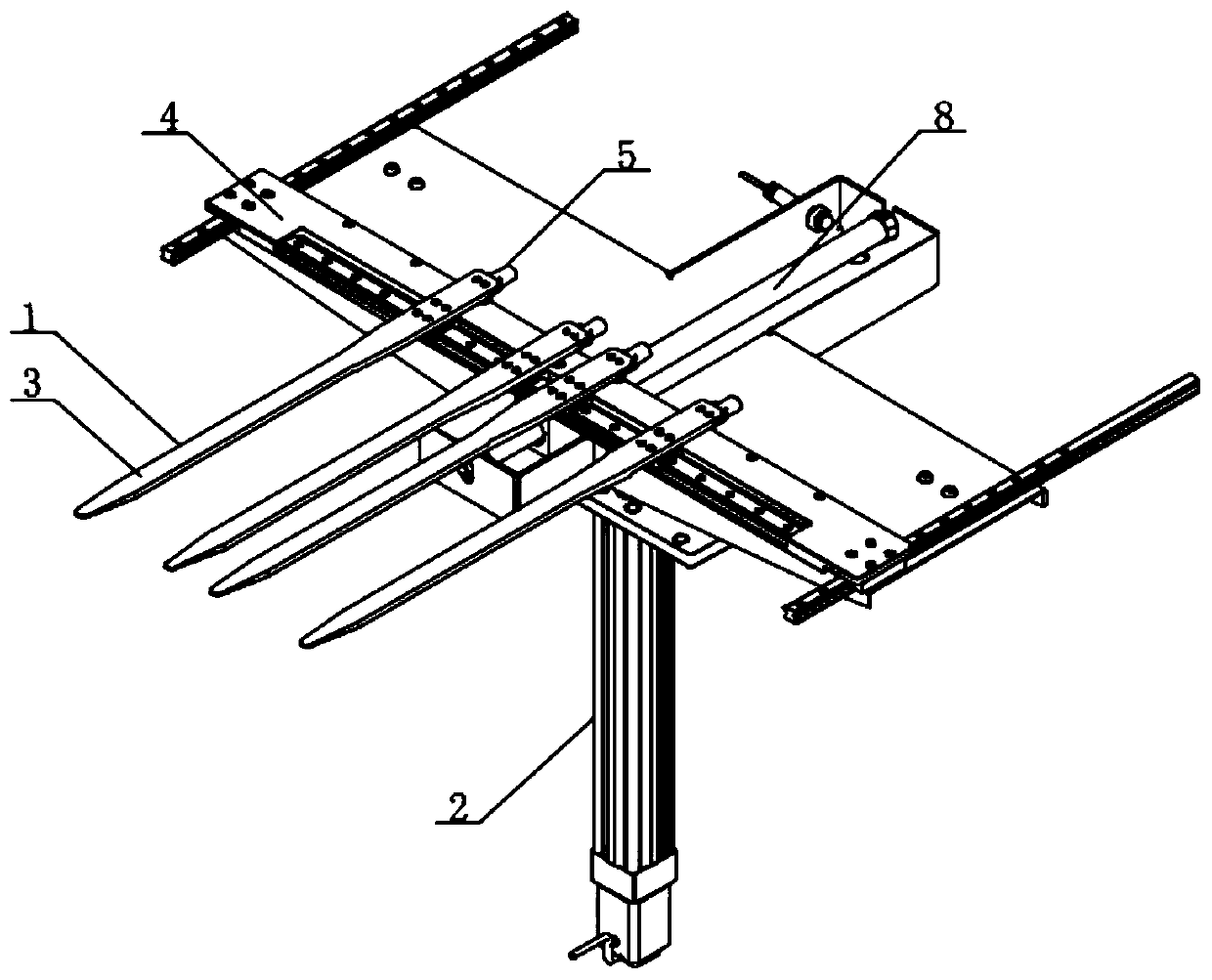

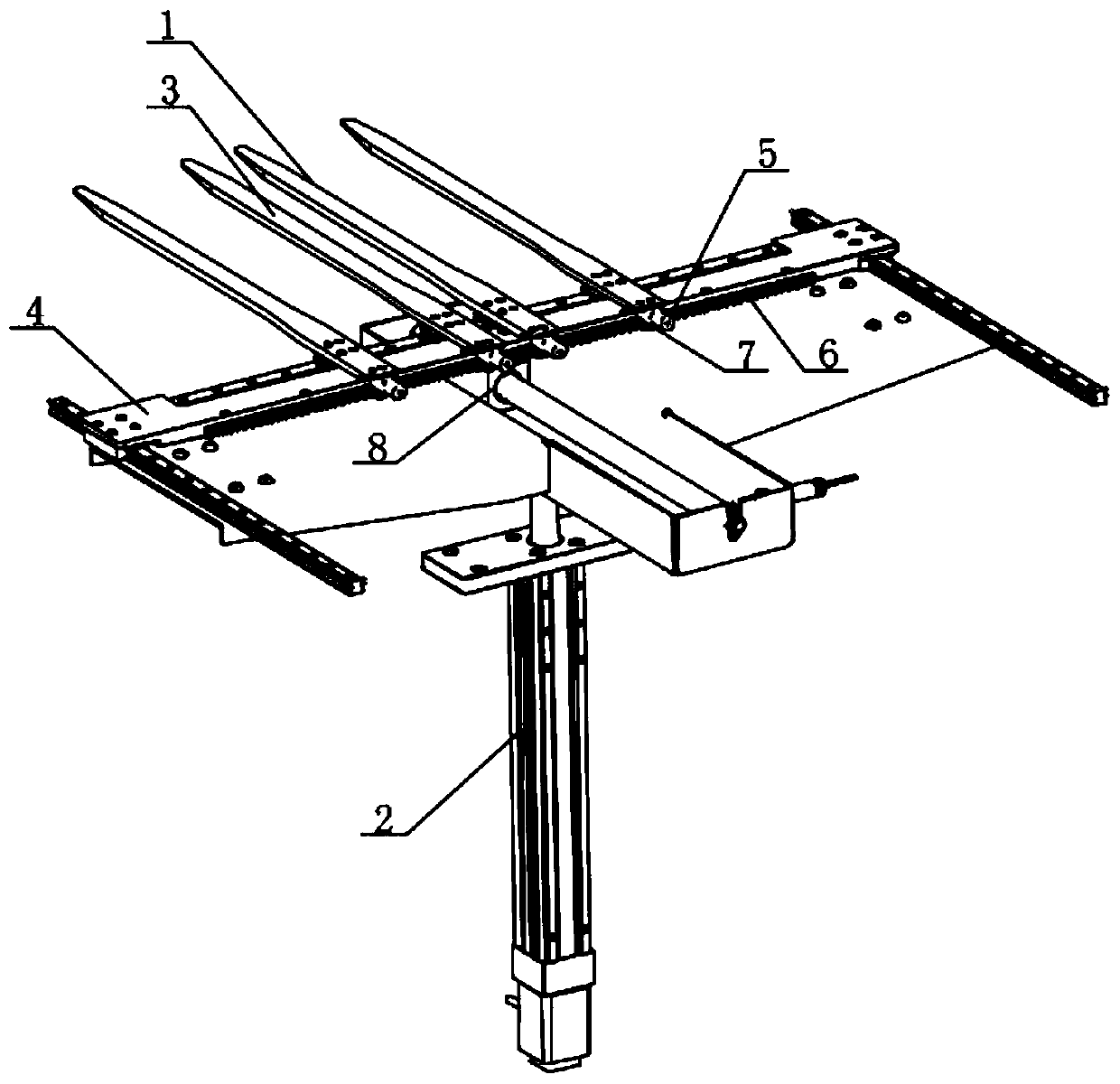

[0031] The slow-fall receiving mechanism for sheet material of embodiment 1 is as figure 1 and figure 2 As shown, the slow-down receiving mechanism includes a receiving module 1 and a lifting mechanism 2. The receiving module 1 is located in the receiving area and is used to receive sheet materials stacked into stacks. The lifting mechanism 2 is used to drive the receiving module 1 increase and decrease slowly.

[0032] When the receiving module 1 receives sheet materials stacked in the receiving area, as the stacking height increases, the receiving module 1 slowly descends to keep the height change of the receiving surface of the receiving module 1 within the set range; the most preferred way is to follow the The stacking height increases, and the receiving module 1 slowly descends to keep the height of the receiving surface of the receiving module 1 constant; so that the distance of the sheet material falling from the top to the receiving surface changes within the set ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com