Special safe power-off device for electric power machine maintenance personnel

A technology for maintenance personnel and power-off devices, applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of not having safe power-off, unable to perform stable lifting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

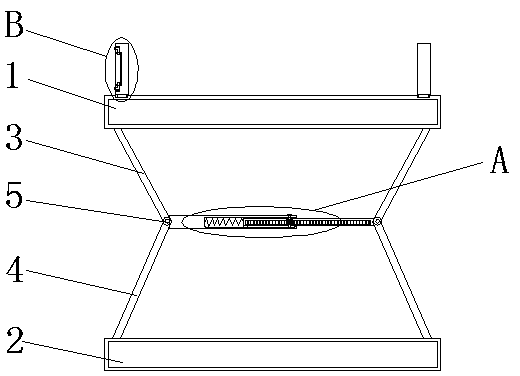

[0025] refer to Figure 1-5 , a special safety power-off device for electric machine maintenance personnel, including a base 2, two first support rods 4 are installed on the top side of the base 2 for rotation, and the tops of the two first support rods 4 are installed with a second rotation through a rotating shaft 5 Two support rods 3, the top ends of the two second support rods 3 are fixedly installed with the same console 1;

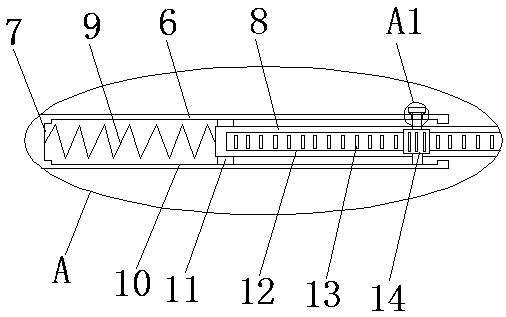

[0026] The sides of the two rotating shafts 5 close to each other are respectively movably installed with a fixed rod 6 and a sliding rod 8, and one end of the fixed rod 6 away from the corresponding rotating shaft 5 is provided with a sliding groove 7, and one end of the sliding rod 8 is slidably installed with a sliding groove 7, one side of the sliding rod 8 is provided with a placement groove 12, and a rack 13 is fixedly installed in the placement groove 12, and a gear 14 located in the sliding groove 7 is meshed with the rack 13;

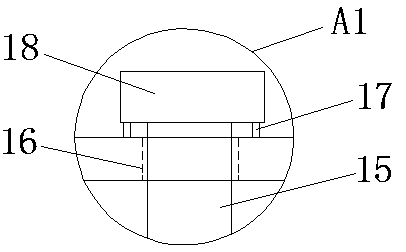

[0027] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com