Wind field test device for planar membrane window

A test device and flat membrane technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of difficult transportation, low test site requirements, high test cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

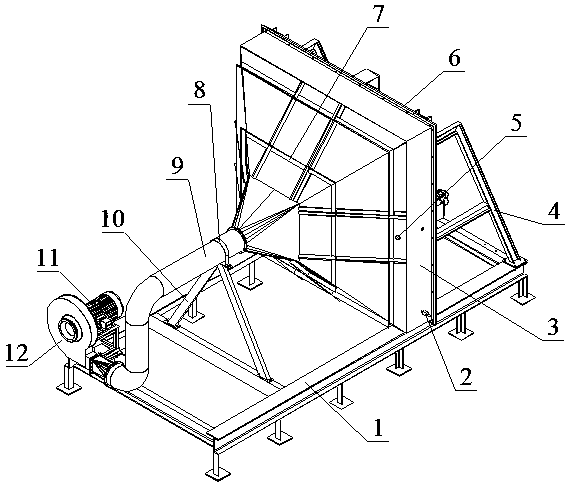

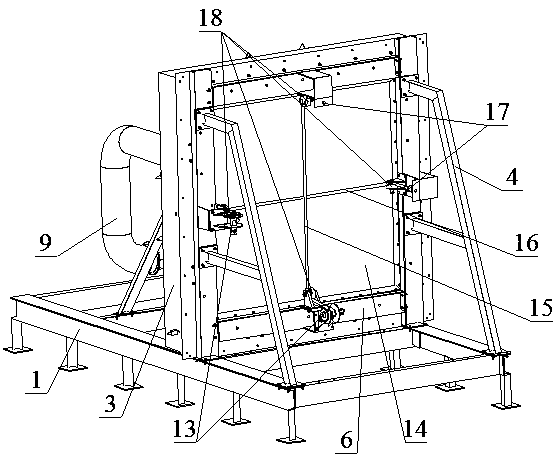

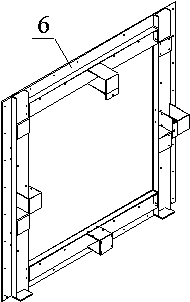

[0018] Such as Figure 1-6 Shown, a kind of wind field test device of plane membrane material window, it comprises base 1, and the upper surface of described base 1 is provided with test frame assembly 6, and wind shield 3 is fixed on the described test frame assembly 6, so The left end of the air cover 3 is connected to the fan 12 through the air duct 9, the fan 12 is connected to the motor 11, and the right end of the air cover 3 is sealed and fixedly connected with a plane film material window 14, and the plane film material The outer side of the window 14 is provided with a cross rope A15 and a rope B16, and one end of the rope A15 and the rope B16 respectively bypasses the pulley assembly 18 and is connected to the tension sensor 17, and the other end of the tension sensor 17 is fixed On the test frame assembly 6, the other ends of the rope A15 and the rope B16 go around the pulley assembly 18 and are connected to the rope fixing shaft 23 of the tensioner assembly 13, bet...

Embodiment 2

[0021] Such as Figure 1-6 Shown, a kind of wind field test device of plane membrane material window, it comprises base 1, and the upper surface of described base 1 is provided with test frame assembly 6, and wind shield 3 is fixed on the described test frame assembly 6, so The left end of the air cover 3 is connected to the fan 12 through the air duct 9, the fan 12 is connected to the motor 11, and the right end of the air cover 3 is sealed and fixedly connected with a plane film material window 14, and the plane film material The outer side of the window 14 is provided with a cross rope A15 and a rope B16, and one end of the rope A15 and the rope B16 respectively bypasses the pulley assembly 18 and is connected to the tension sensor 17, and the other end of the tension sensor 17 is fixed On the test frame assembly 6, the other ends of the rope A15 and the rope B16 go around the pulley assembly 18 and are connected to the rope fixing shaft 23 of the tensioner assembly 13, bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com