Working condition variable reciprocating friction and wear tester based on double-degree-of-freedom flexible hinge

A friction and wear test, flexible hinge technology, applied in the direction of strength characteristics, testing wear resistance, measuring devices, etc., can solve the problem of difficult to achieve fast response to variable load, variable speed, variable friction pair end face pressure, etc., to improve stability stability and measurement accuracy, avoid mutual interference, and avoid the effects of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations. However, what has been described is only a part of the embodiments of the present invention, not all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work all belong to the protection scope of the present invention. In addition, the following "left, right, up, down, front, Orientation words such as "back" are only directions established based on the convenience of illustrations and descriptions, and others should not use them to raise rebuttals.

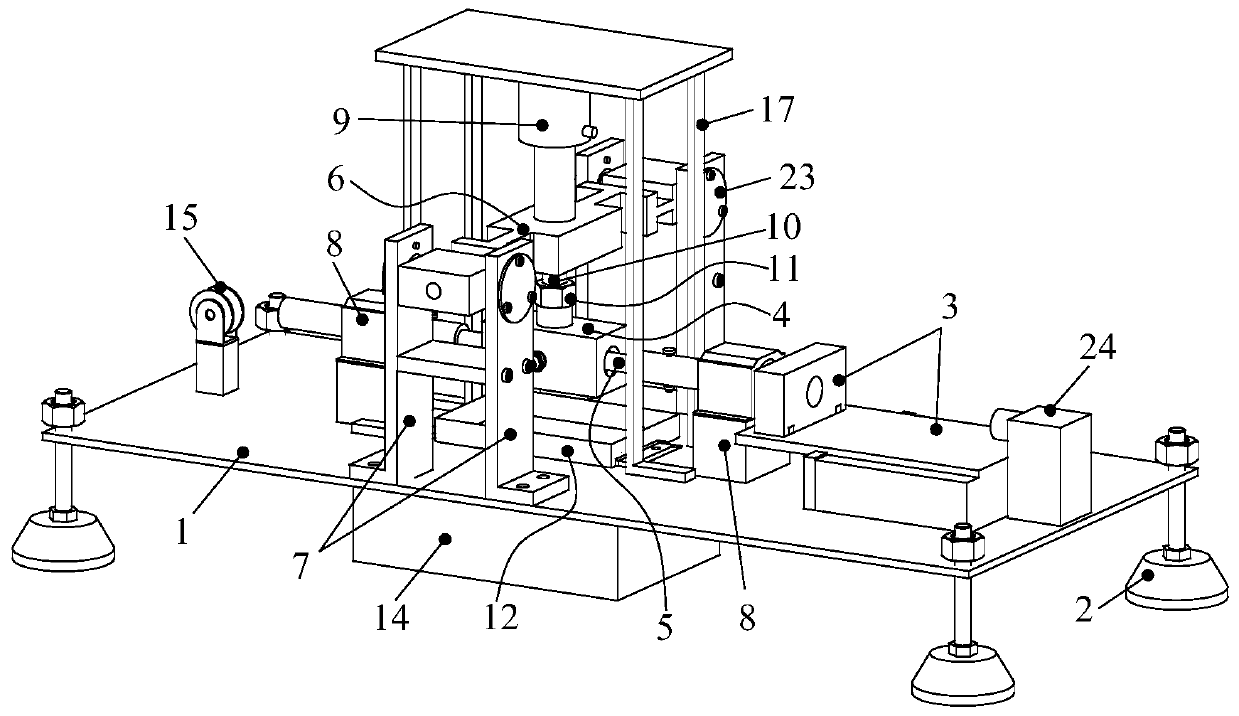

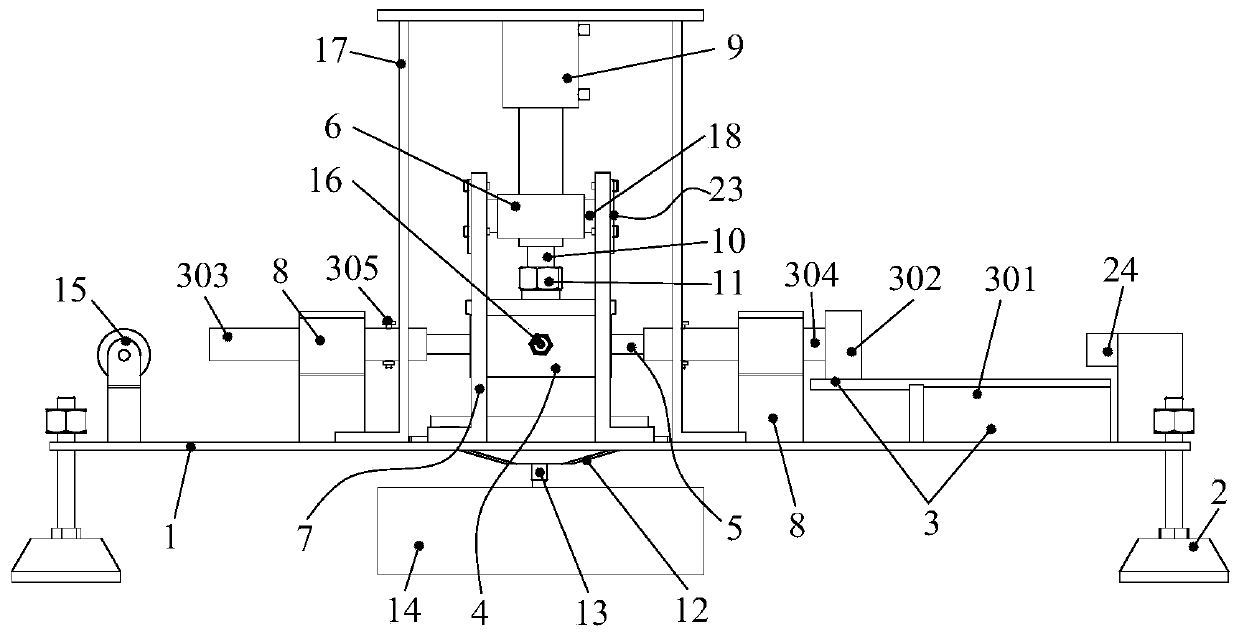

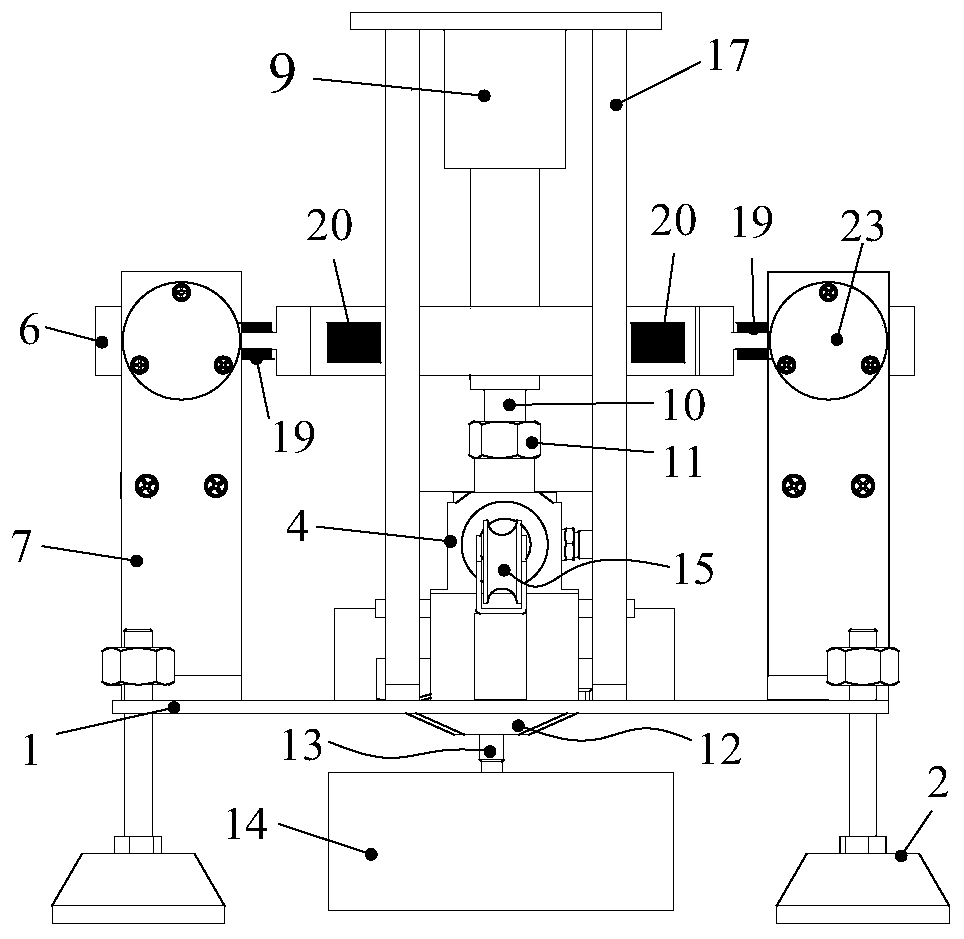

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a reciprocating friction and wear testing machine based on a two-degree-of-freedom flexible hinge, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com