Positioner of bidirectional glass sliding door

A glass door and locator technology, which is applied to building fastening devices, wing leaf fastening devices, buildings, etc., can solve the problems of reduced constant temperature effect, too fast communication, and reduced floor spring elasticity, so as to reduce the strength of force , prolong the service life, reduce the effect of elastic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

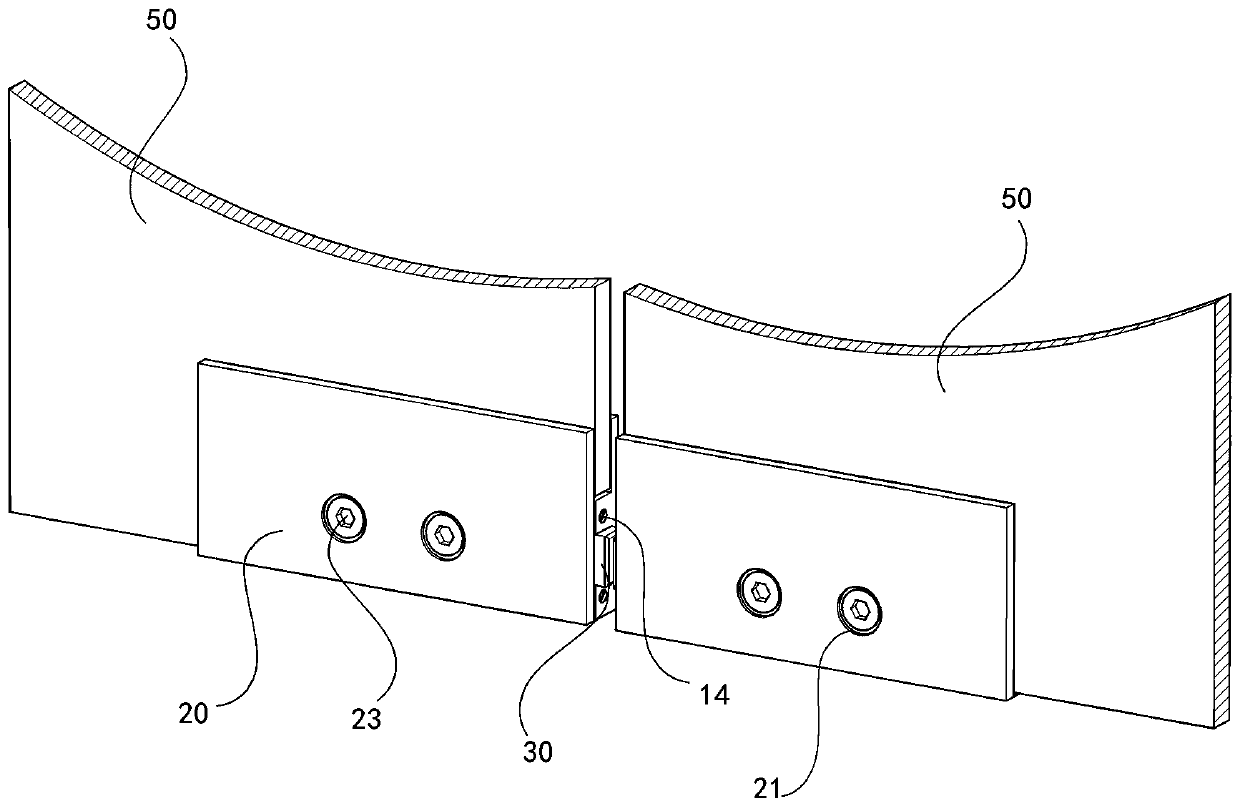

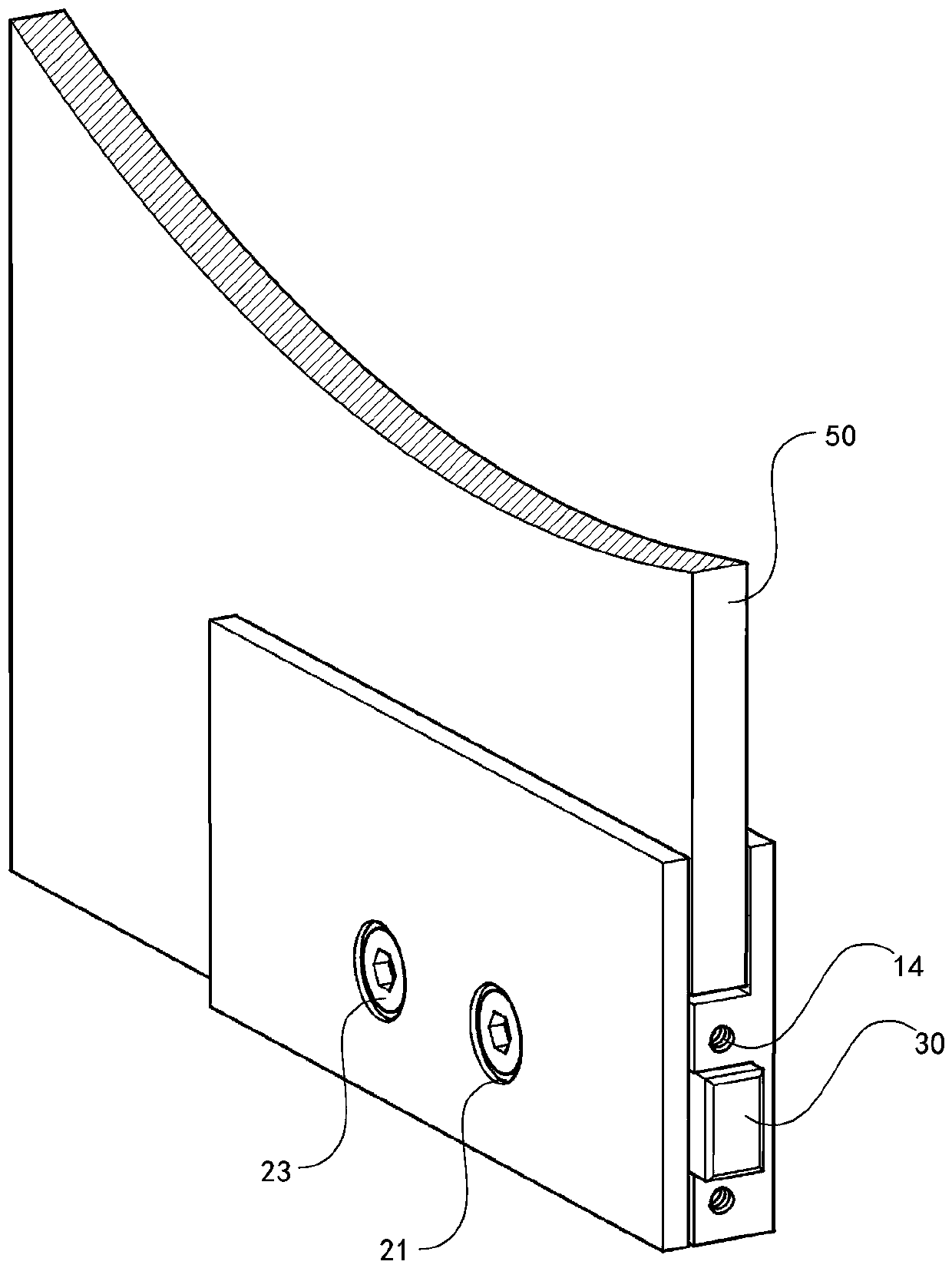

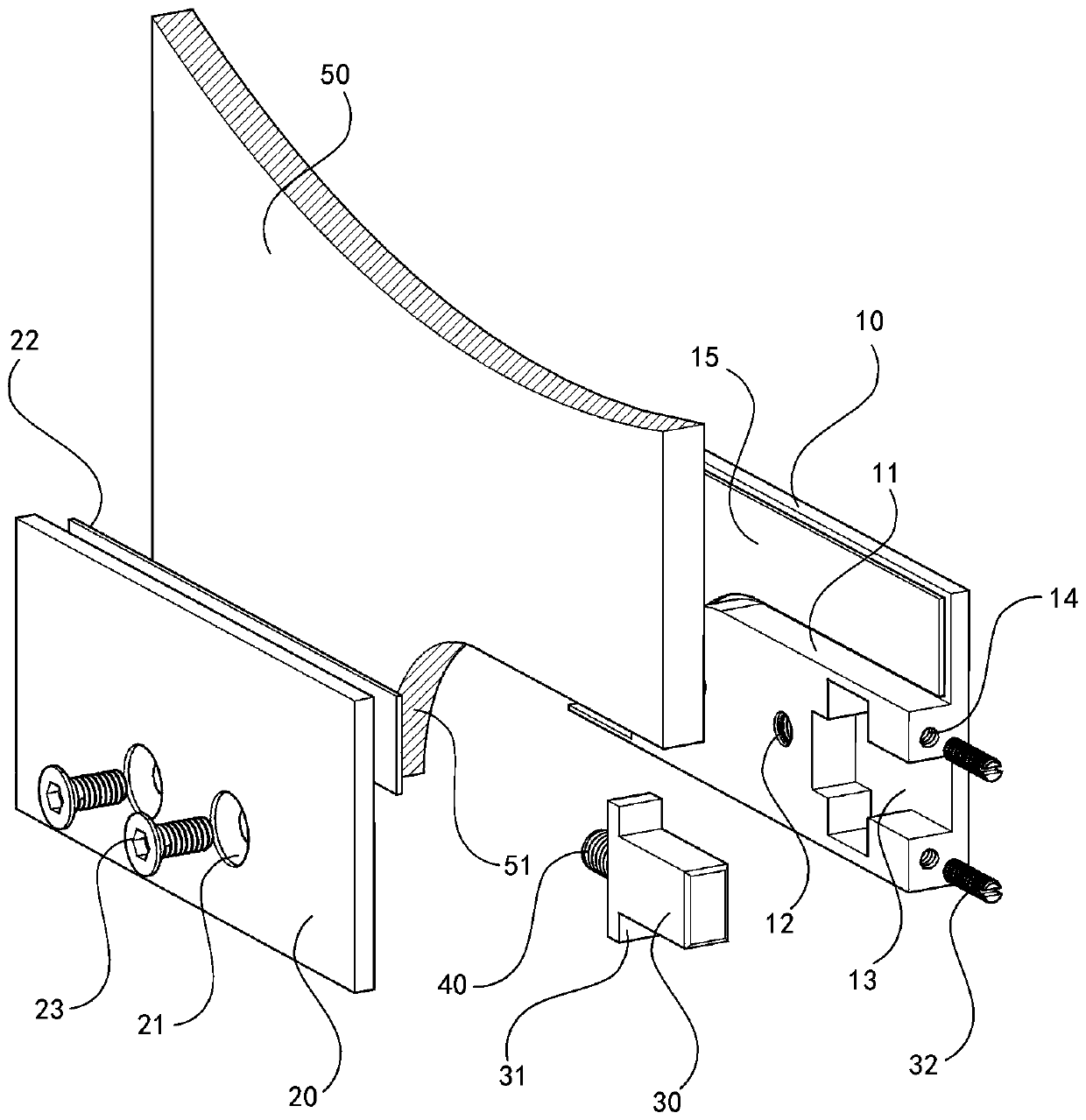

[0016] Below, the present invention will be further described in conjunction with accompanying drawing and embodiment: Figure 1 to Figure 4 As shown, a two-way side-opening glass door positioner includes a main splint 10, an auxiliary splint 20, a strong magnetic head 30, a lug 31, a spring 40, and a glass door 50; the inner side of the main splint 10 is provided with a main splint. Gasket 15 and convex plate 11, the inner side of convex plate 11 is provided with positioning threaded hole 12 and groove 13, and the vertical edge of convex plate 11 is provided with the opening of adjusting threaded hole 14 and groove 13; A through hole 21 is provided, and the inner side is provided with an anti-slip gasket 22 for the auxiliary splint; one end of the strong magnetic head 30 is provided with a lug 31, and the strong magnetic head 30 is placed in the groove 13; the two ends of the spring 40 are respectively opposite to each other. The convex plate 11 and the strong magnetic head 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com