A kind of tpu adhesive and hot melt adhesive film and application

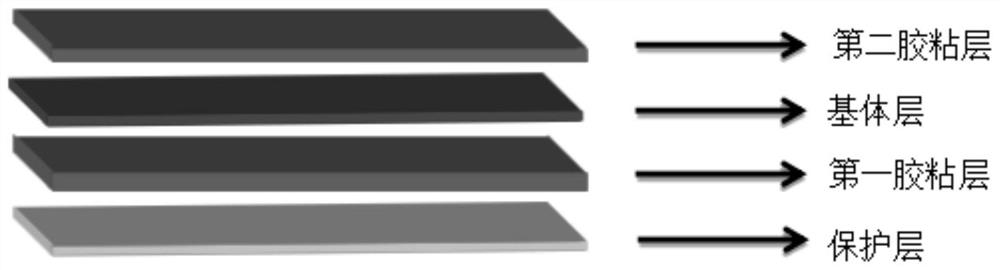

A hot-melt adhesive film and adhesive technology, applied in the direction of adhesive, adhesive type, heat-activated film/sheet, etc., can solve the problems of not improving the quality and beauty of clothing, affecting the comfort of seamless sports clothing, and shortening the service life. , to achieve good adhesion and washing resistance, which is conducive to large-scale and rapid industrial operations, and overcomes the effects of poor resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A TPU adhesive, including the following components of weight sharing:

[0048]

[0049] The dicate polyester TPU particles A are prepared from the following calculated raw materials: 70% polya-ethylene glycol esters 1000, 27% 4,4-dibenzene Okolin diisocyanate, 3% 1,4-butanediol

[0050] The diacorate polyester TPU particles B are prepared by the twin screw extruder by weight percentage of raw materials: 65% polycaricate butanol ester 1000, 30% 4,4-dibenzene Othane diisocyanate, 5% new pentylene glycol.

[0051] The preparation method of the above TPU adhesive includes the following steps:

[0052] The dicate polyester TPU particles A (the melt mass flow rate of 45 g / 10 minutes, the softening point is 110 ° C), the dicate polyester TPU particles B (the melt mass flow rate is 20g / 10) The minute, the softening point is 130 ° C), the modified copolyester 3112, the polycarbonate, the antioxidants 1010, the ultraviolet absorber UV-328 are mixed, and the granulation is extru...

Embodiment 2

[0058] A TPU adhesive, including the following components of weight sharing:

[0059]

[0060] The dicate polyester TPU particles are prepared by a double screw extruder by weight percentage of raw materials: 79% polya-ethylene glycol ester 2000, 18% 4,4-diphenyl group Methane diisocyanate and 3% 1,4-butanediol Download Adobe Reader

[0061] The polytetrahydrofuran polyether TPU particles are prepared from the following calculated raw material by a twin-screw extruder 1500, 29% isophorone diisocyanate, 2% 1, 4 - butanediol and 9% new pentylene glycol.

[0062] The preparation method of the above TPU adhesive includes the following steps:

[0063] The dicate polyester TPU particles (the melt mass flow rate of 35 g / 10 minutes, the softening point is 120 ° C), and the polytex hydrofuran polyether TPU granules (the melt mass flow rate is 25 g / 10 minutes, softened The point is 135 ° C), the polycarbonate, an antioxidant 1076, and the ultraviolet absorber UV-9 are mixed uniform, a...

Embodiment 3

[0069] A TPU adhesive, including the following components of weight sharing:

[0070]

[0071]

[0072] The diacorate polyester TPU particles A are prepared by the twin-screw extruder by weight percentage of raw materials: 70% polycaricate butanol ester 1000, 27% 4,4-dibenzene Okinane diisocyanate and 3% 1,4-butanediol;

[0073] The dicate polyester TPU particles B are prepared by the twin screw extruder by weight percentage of raw materials: 60% polycaric acid has been added 1000, 30% 4, 4'-two Cyclohexylmetane diisocyanate, 6% 1,4-butanediol and 7% neovanediol.

[0074] The preparation method of the above TPU adhesive includes the following steps:

[0075] The dicate polyester TPU particles A (the melt mass flow rate of 30 g / 10g / 10g, the softening point is 120 ° C), the dicate polyester TPU particles B (the melt mass flow rate is 50g / 10) The minute, the softening point is 115 ° C), the polybiimine, the modified copolyester 5120, the antioxidant 1076, the ultraviolet ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com