Cushion for air bag gas generator

A technology of gas generator and cushioning pad, which is applied in the field of cushioning pads, can solve the problems of inability to obtain elastic force, unsuitable gas generating agent, etc., and achieve the effect of avoiding dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

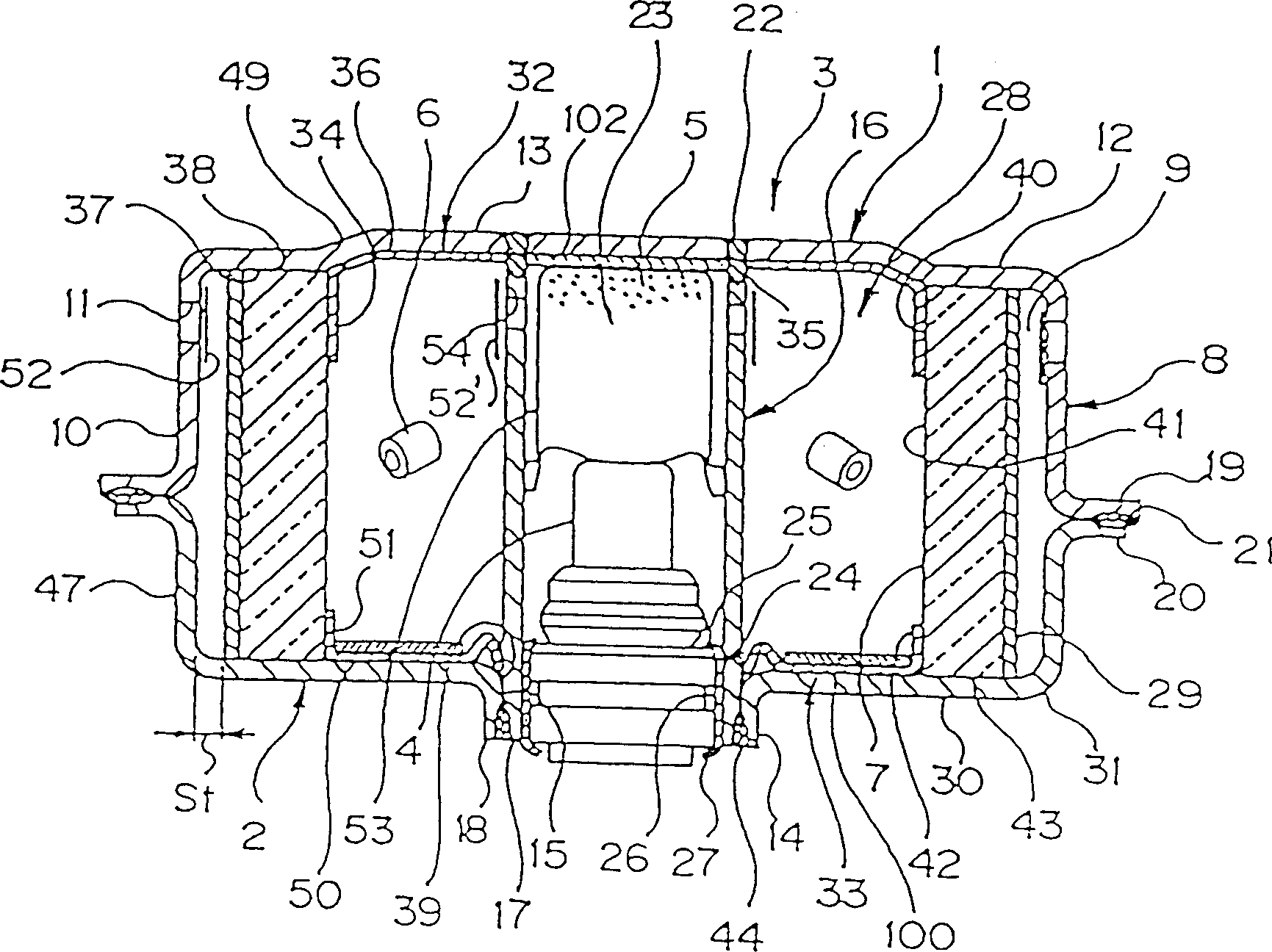

[0034] figure 1 It is a cross-sectional view of the air bag gas generator of the present invention. This embodiment is mainly used as a gas generator having a casing with an outer diameter of about 70 mm. In this gas generator, an inner cylindrical member 16 partitions an outer casing 3 constituted by a diffusion shell 1 and a closing shell 2 into an igniter storage chamber 23 and a combustion chamber 28 for a gas generating agent. An ignition device that ignites and burns the gas generating agent 6 when triggered by an impact, that is, an ignition device including an igniter 4 and a transfer charge 5 in this embodiment, is housed in the ignition device storage chamber 23 . The combustion chamber 28 is provided with: a gas generating agent 6 ignited by an ignition device to generate combustion gas; a first cushion member 100 supporting the gas generating agent and preventing its movement; and a second cushion member 102 supporting a conduction fuel 5 .

[0035] In this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com