A kind of ironing underwear and its preparation process

An underpants and ironing technology, applied in the field of underpants, can solve the problems of poor softness and resilience of rubber, low stretch resilience of underpants fabrics, detachment between layers of underpants fabrics, etc., to achieve high air permeability and improve wearing lightness. , the effect of good softness and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

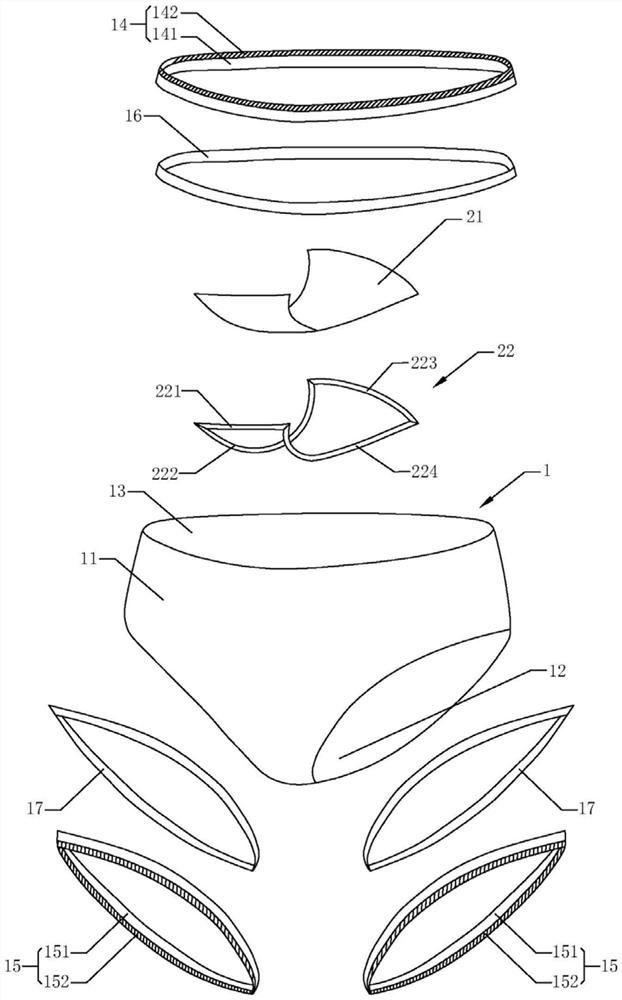

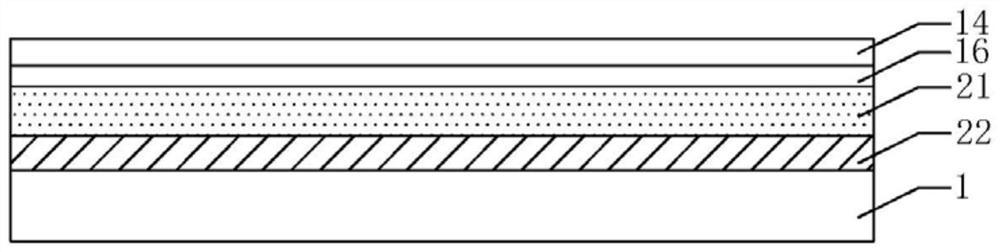

[0067] See Figure 1-4 , a kind of iron-on underwear, including an underwear body 1 and an iron-on member 2, the underwear body 1 includes a one-piece front panel 11, a crotch portion 12 and a rear panel 13; The provided crotch cloth 21, the hot-melt adhesive layer 22 arranged on the periphery of the crotch cloth 21, the release film layer 23 covering the lower surface of the hot-melt adhesive layer 22, the crotch of the underwear body 1 12 is bonded and connected with the crotch cloth 21 through a hot-melt adhesive layer 22; the hot-melt adhesive layer 22 is made of polyurethane composite hot-melt adhesive.

[0068] The thickness of the crotch cloth 21 is 0.8-1.2mm, the thickness of the hot melt adhesive layer 22 is 0.23-0.28mm, and the thickness of the release film layer 23 is 0.8-1.2mm; the hot melt adhesive layer 22 includes The first adhesive area 221 , the second adhesive area 222 , the third adhesive area 223 and the fourth adhesive area 224 are connected end to end. ...

Embodiment 2

[0078] The difference between this embodiment and above-mentioned embodiment 1 is:

[0079] Described polyurethane composite hot-melt adhesive comprises the raw material of following weight portion:

[0080]

[0081] The NCO / OH ratio of the NCO-terminated polyurethane prepolymer is 1.8.

[0082] Each part of the mixed monomer comprises 2 parts of methyl methacrylate, 0.5 part of hydroxyethyl acrylate and 4 parts of N-methylol acrylamide; the filler is made of talcum powder, calcium carbonate and paraffin in a weight ratio of 1.2 : a mixture composed of 1:0.6; the catalyst is a mixture composed of dimorpholine diethyl ether, dimethylethanolamine and dibutyltin dilaurate in a weight ratio of 3:2.0:1.

[0083] Described polyurethane composite hot-melt adhesive is made by following steps:

[0084] Step (1): Add the filler to the NCO-terminated polyurethane prepolymer in parts by weight, add polyisobutylene and mixed monomers in sequence after mixing and dispersing, mix and st...

Embodiment 3

[0100] The difference between this embodiment and above-mentioned embodiment 1 is:

[0101] Described polyurethane composite hot-melt adhesive comprises the raw material of following weight portion:

[0102]

[0103] The NCO / OH ratio of the NCO-terminated polyurethane prepolymer is 1.9.

[0104] Every part of said mixed monomer comprises 2.2 parts of methyl methacrylate, 0.6 part of hydroxyethyl acrylate and 4.5 parts of N-methylol acrylamide; : 1:0.7 mixture; the catalyst is a mixture of dimorpholine diethyl ether, dimethylethanolamine and dibutyltin dilaurate in a weight ratio of 3.5:1.9:1.

[0105] Described polyurethane composite hot-melt adhesive is made by following steps:

[0106] Step (1): In parts by weight, add the filler to the NCO-terminated polyurethane prepolymer, after mixing and dispersing, add polyisobutylene and mixed monomers in sequence, mix and stir at 100°C for 23min, then cool down to 80°C ℃ insulation to prepare the pre-reactant;

[0107] Step (2):...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com