Epoxy resin composition suitable for planar bump packaging and preparation method thereof

A planar bump type, epoxy resin technology, applied in the direction of epoxy resin glue, aldehyde/ketone condensation polymer adhesive, adhesive type, etc., can solve the problems affecting chemical cap opening, Tg high water absorption rate, etc. , to meet the requirements of cap opening and reliability, low water absorption and moderate Tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, an epoxy resin composition suitable for planar bump packaging, the composition mainly includes epoxy resin, phenolic resin, spherical silica powder, wetting and dispersing agent and other additives,

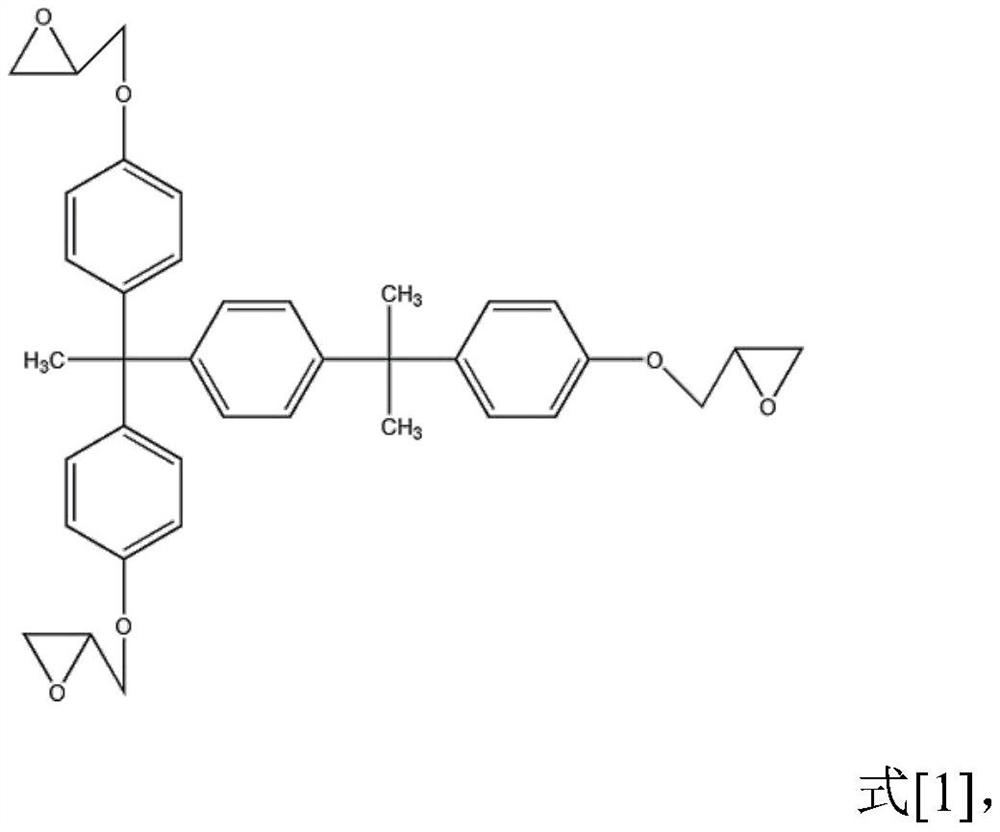

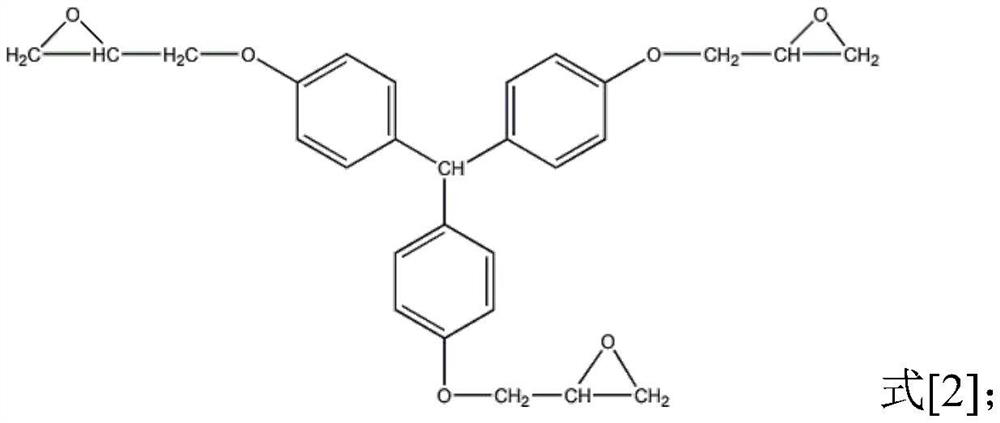

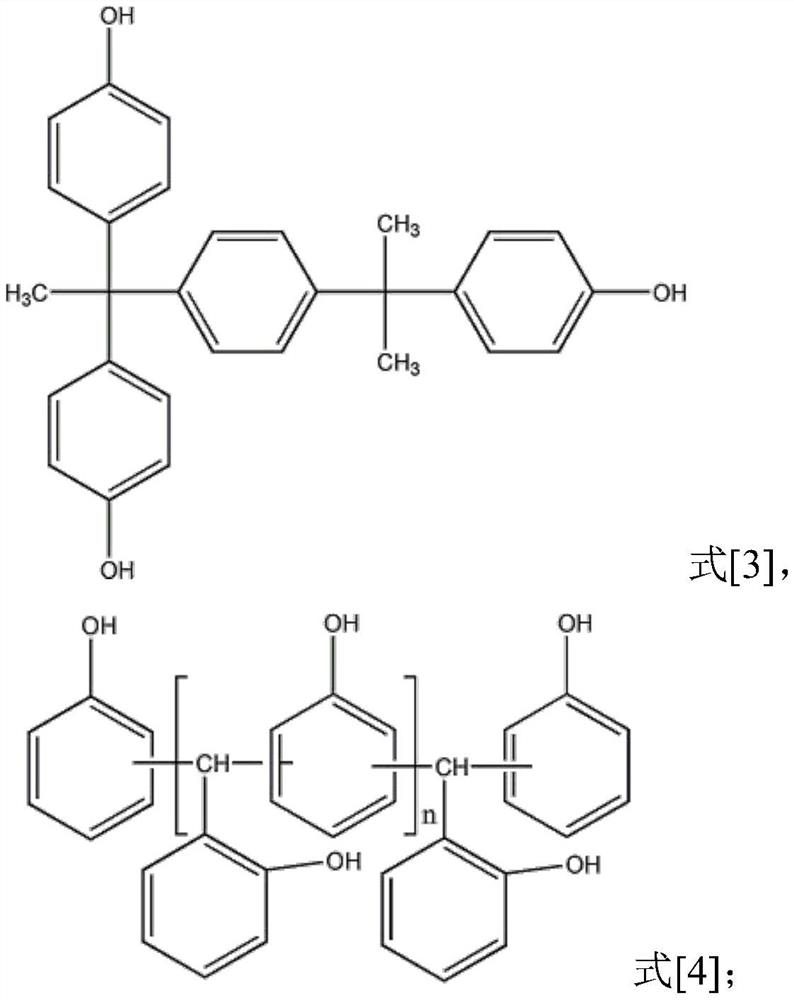

[0023] Described epoxy resin is a kind of in the epoxy resin represented by formula [1] and formula [2], and its content is 3% of composition gross mass, and described phenolic resin is formula [3] and formula One of the phenolic resins represented by [4], the content of which is 2% of the total mass of the composition;

[0024] Spherical silicon powder is silicon powder with a maximum particle size of 75um and silicon powder with a maximum particle size of 5um. Silicon powder with a maximum particle size of 5um accounts for 15% of the total mass of spherical silicon powder, and silicon powder with a maximum particle size of 75um occupies spherical 85% of the total mass of microsilica powder, and the content of spherical microsilica powder is 92% of the total...

Embodiment 2

[0027] Embodiment 2, an epoxy resin composition suitable for planar bump packaging, the composition mainly includes epoxy resin, phenolic resin, spherical silica powder, wetting and dispersing agent and other additives,

[0028] Described epoxy resin is a kind of epoxy resin represented by formula [1] and formula [2], and its content is 10% of composition gross mass, and described phenolic resin is formula [3] and formula [ 4] a kind of phenolic resin represented, its content is 3% of composition gross mass;

[0029] Spherical silica powder contains silica powder with a maximum particle size of 75um and 20um. The silica powder with a maximum particle size of 20um accounts for 19% of the total mass of spherical silica powder, and the maximum particle size of 75um accounts for 81% of the total mass of spherical silica powder. %, the content of spherical silica powder is 86% of the total content of the composition;

[0030] The wetting and dispersing agent is a polar long-chain ...

Embodiment 3

[0032] Embodiment 3, an epoxy resin composition suitable for planar bump packaging, the composition mainly includes epoxy resin, phenolic resin, spherical silica powder, wetting and dispersing agent and other additives,

[0033] Described epoxy resin is the mixture that is formed by the epoxy resin represented by formula [1] and formula [2], and its content is 5% of composition gross mass, and described phenolic resin is formula [3] and formula [ 4] represents the mixture of phenolic resins, the content of which is 3% of the total mass of the composition;

[0034] Spherical silicon powder is a mixture of silicon powders with a maximum particle size of 75um, 20um and 5um. Silicon powder with a maximum particle size of 5um, silicon powder with a maximum particle size of 20μm, and silicon powder with a maximum particle size of 75um account for 7% of the total content of spherical silicon powder. %, 17% and 76%, the content of spherical silica powder is 89% of the total content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com